Jumbo Sandpaper Rolls

- Home

- Jumbo Sandpaper Rolls

Categories

Jumbo Sandpaper Rolls

Product Overview

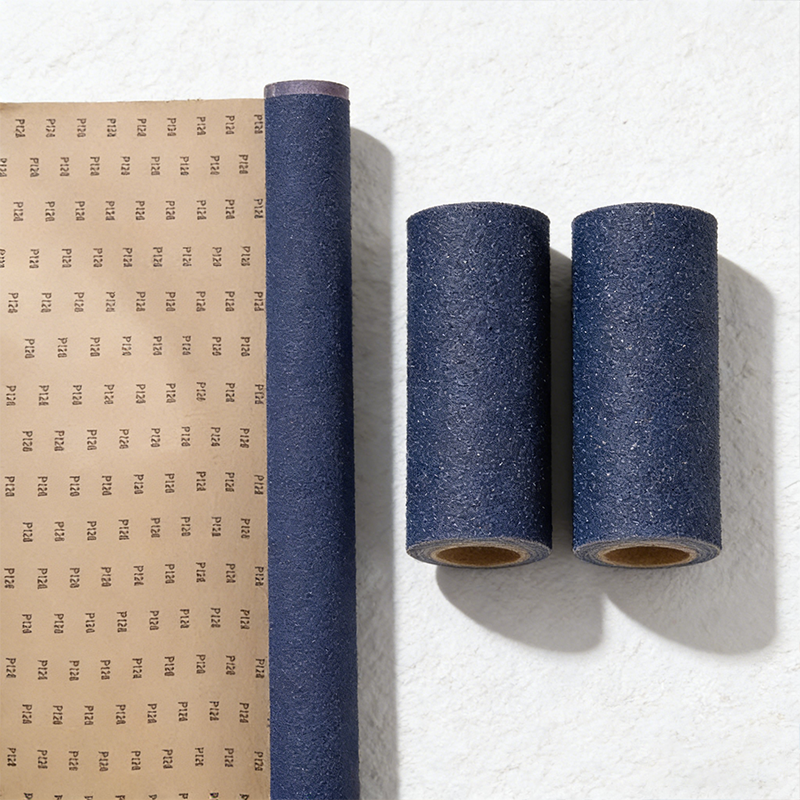

Stable Coating and Consistent Performance from Start to End

Our jumbo sandpaper rolls are manufactured using stable coating processes and strict abrasive grain distribution control, ensuring consistent cutting performance and surface finish from the beginning to the end of each roll.

They are specifically designed for industrial slitting and die-cutting operations, balancing cutting efficiency, paper backing strength, flexibility, and processing stability for high-volume continuous production.

Product Description

Technical Specifications of Jumbo Sandpaper Rolls

Grit Range, Roll Size and Customization

| Item |

Specification |

|

Abrasive Type |

Aluminum Oxide (AO) / Silicon Carbide (SiC) |

| Grit Range |

P40 – P3000 |

|

Backing Grade |

C / D / E weight paper |

|

Coating Method |

Electrostatic coating |

| Bonding |

Resin over Resin (Full resin bond) |

|

Roll Width |

Available in customized widths |

| Roll Diameter |

Standard or custom diameters |

| OEM / ODM Service |

Supported(Fully supported) |

Jumbo Sandpaper Rolls

Coated Abrasive Jumbo Rolls for Industrial Converting and Manufacturing

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Base Material for Sandpaper Sheets, Discs and Custom Shapes

Jumbo sandpaper rolls are the base raw material for sandpaper sheets, sanding discs, and various custom-shaped abrasives. They are primarily used for slitting, die-cutting, and automated converting, making them one of the most essential semi-finished forms in coated abrasive systems.

————————————————————————————————————————————————————————————————————————————————————

Product Overview

Stable Coating and Consistent Performance from Start to End

Our jumbo sandpaper rolls are manufactured using stable coating processes and strict abrasive grain distribution control, ensuring consistent cutting performance and surface finish from the beginning to the end of each roll.

They are specifically designed for industrial slitting and die-cutting operations, balancing cutting efficiency, paper backing strength, flexibility, and processing stability for high-volume continuous production.

————————————————————————————————————————————————————————————————————————————————————

Abrasive Grain Selection & Workpiece Compatibility

Choosing the Right Abrasive for Cutting Behavior and Surface Finish

Different workpiece materials require different cutting sharpness, durability, and surface consistency. Jumbo sandpaper rolls are available with various abrasive systems to match specific applications.

Aluminum Oxide

Suitable for wood, carbon steel, and general metal processing. It offers stable cutting performance and balanced service life, making it the most cost-effective and widely used industrial abrasive.

Silicon Carbide

Ideal for fine sanding, stainless steel, non-metal materials, and coating preparation applications where surface consistency is critical.

————————————————————————————————————————————————————————————————————————————————————

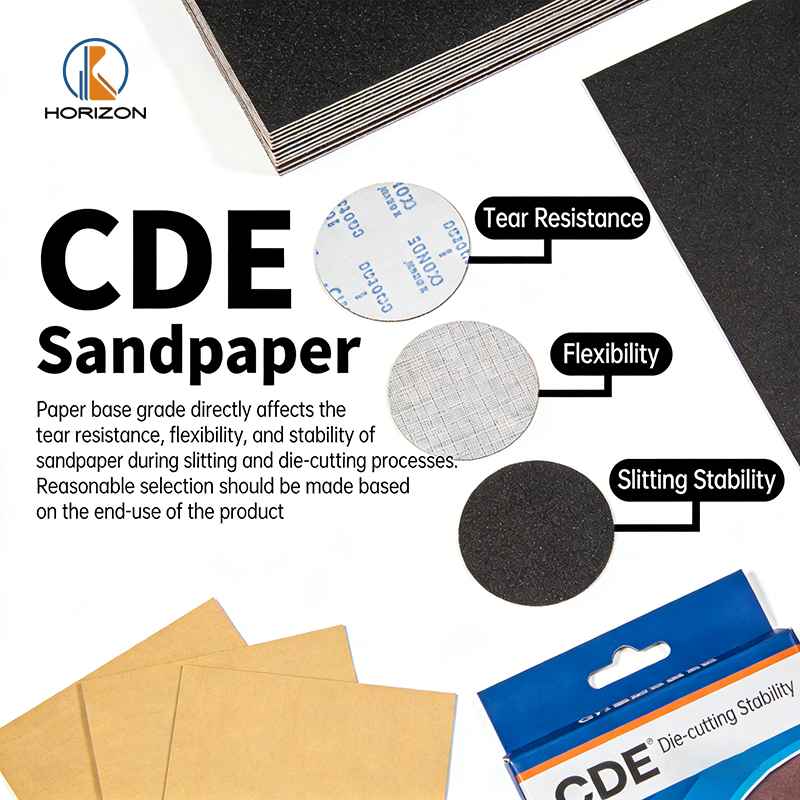

Paper Backing Selection by Application

Balancing Flexibility, Strength and Converting Stability

Paper backing weight directly affects tear resistance, flexibility, and stability during slitting and die-cutting. It should be selected according to the finished product and sanding method.

C-weight paper

High flexibility for hand sanding sheets, small die-cut products, and light-duty applications.

D-weight paper

Balanced strength and flexibility, ideal for most sandpaper sheets and sanding discs.

E-weight paper

High-strength paper backing designed for machine sanding and heavy-duty applications requiring dimensional stability.

————————————————————————————————————————————————————————————————————————————————————

Coating Density & Grit Selection

Optimizing Cutting Efficiency and Finished Product Yield

Coating density and grit range directly affect cutting aggressiveness, chip clearance, and product consistency, and should be matched to the sanding stage.

P40 – P80: Coarse sanding and rapid stock removal

P100 – P180: Medium sanding and surface leveling

P220 – P400: Fine sanding and coating preparation

Above P600: Fine finishing and surface improvement

————————————————————————————————————————————————————————————————————————————————————

Key Advantages of Jumbo Sandpaper Rolls

High Yield, Low Loss and Consistent Quality

- Uniform coating for consistent cutting performance

- High roll stability to reduce slitting and converting loss

- Suitable for high-speed automated processing

- Excellent batch consistency for finished products

- Long-term stable supply and customized production supported

————————————————————————————————————————————————————————————————————————————————————

Abrasive Grain and Paper Backing Options

Flexible Combinations for Different Applications

Abrasive grain options:

Aluminum Oxide: General woodworking and metal sanding

Silicon Carbide: Fine finishing and surface preparation

Paper backing options:

- C-weight paper: Good flexibility for hand sanding

- D-weight paper: Balanced strength and flexibility

- E-weight paper: High strength for machine sanding

————————————————————————————————————————————————————————————————————————————————————

Coating and Bonding Technology

Electrostatic Coating with Full Resin Bond

Electrostatic coating technology is used to orient abrasive grains for improved cutting efficiency and consistency. Combined with a full resin bonding system, it enhances grain retention and extends product service life.

————————————————————————————————————————————————————————————————————————————————————

Applications and Converting Uses

Ideal for Industrial Abrasive Converting

- Sandpaper sheet production

- Velcro sanding discs

- PSA sanding discs

- Custom-shaped and die-cut abrasives

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Custom Abrasive Manufacturing from Direct Factory

OEM Manufacturing

We provide reliable OEM manufacturing services based on proven product structures, including specification customization, packaging design, and private labeling.

ODM Development

With extensive coated abrasive manufacturing experience, we support ODM development from application analysis and material optimization to sample development and mass production.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our Jumbo Sandpaper Rolls

Direct Coated Abrasive Manufacturer

As a direct coated abrasive manufacturer, we offer stable jumbo roll production capacity with strict quality control, providing long-term, consistent, and traceable industrial-grade sandpaper materials.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

Maintain Quality Before Converting

- Store in a dry, temperature-controlled environment

- Allow acclimation before converting

- Avoid moisture, heavy pressure, and direct sunlight