Aluminum Oxide Sanding Belts

- Home

- Aluminum Oxide Sanding Belts

Categories

Aluminum Oxide Sanding Belts

Aluminum Oxide Sanding Belts

Reliable General-Purpose Sanding Belts for Wood and Metal Processing

Aluminum oxide abrasives offer stable cutting behavior and predictable wear patterns, making them highly reliable for continuous industrial sanding.

Compared to premium abrasives, aluminum oxide belts provide superior cost efficiency and process stability under medium load conditions.

Product Description

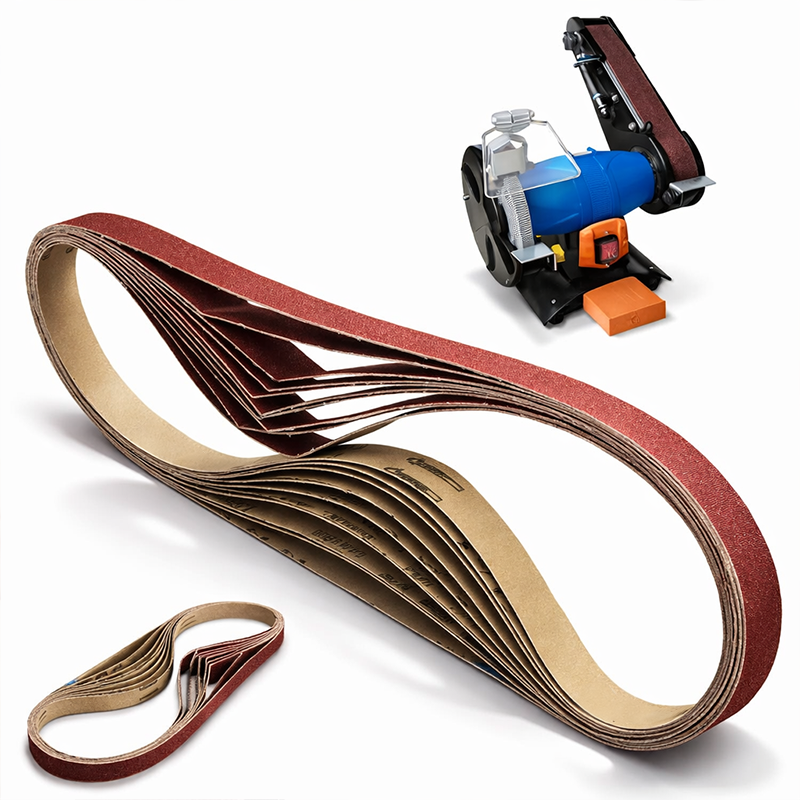

Aluminum Oxide Sanding Belts

Reliable General-Purpose Sanding Belts for Wood and Metal Processing

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

|

Item |

Specification |

| Abrasive |

Aluminum Oxide (AO) |

|

Backing |

X-weight / Y-weight Cloth |

| Grit Range |

P36 – P400 |

|

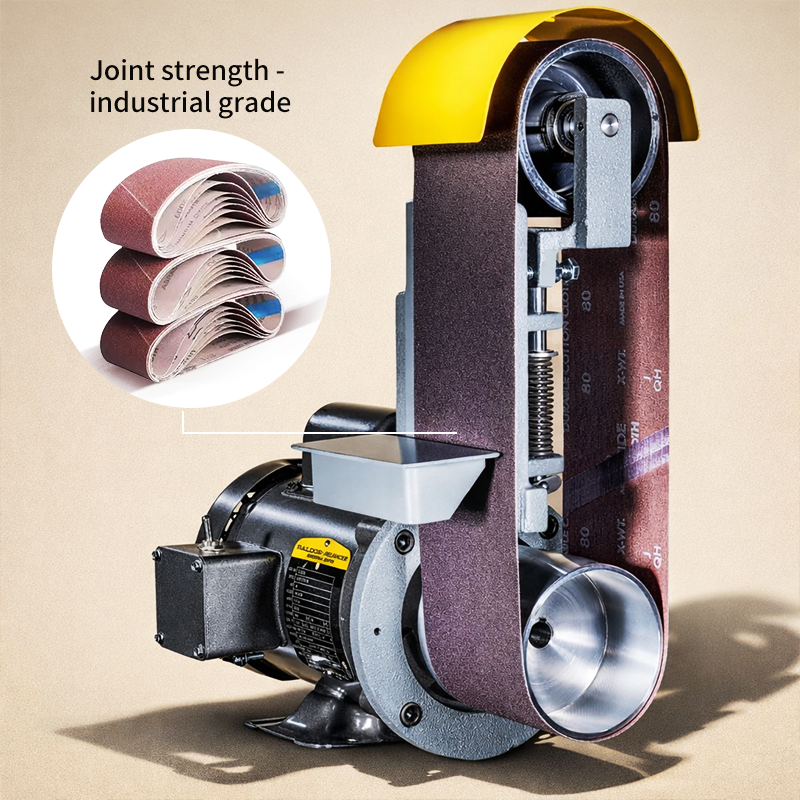

Joint Type |

Lap Joint / Butt Joint |

| Bonding |

Full Resin Bond |

|

Dimensions |

Customized per machine specifications |

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Core Sanding Belt for Standard Industrial Applications

Aluminum oxide sanding belts are general-purpose industrial belts designed for wood, carbon steel, and composite materials. They are widely used on wide belt sanders, vertical belt grinders, and edge sanding machines.

————————————————————————————————————————————————————————————————————————————————————

Product Overview

Stable Cutting, Predictable Wear and Long Service Life

Aluminum oxide abrasives offer stable cutting behavior and predictable wear patterns, making them highly reliable for continuous industrial sanding.

Compared to premium abrasives, aluminum oxide belts provide superior cost efficiency and process stability under medium load conditions.

————————————————————————————————————————————————————————————————————————————————————

Belt Backing & Machine Compatibility

Selecting Backing by Tension and Machine Type

Belt backing selection directly affects tension resistance and dimensional stability during operation and must match machine requirements.

X-weight cloth backing

Suitable for medium-tension machines such as vertical belt grinders and edge sanders.

Y-weight cloth backing

Designed for high-tension wide belt sanders with superior tensile strength.

————————————————————————————————————————————————————————————————————————————————————

Process Stages & Grinding Strategy

From Stock Removal to Surface Preparation

- Rough grinding: Rapid stock removal and shape establishment

- Medium grinding: Surface leveling and scratch reduction

- Fine preparation: Preparing surfaces for coating or finishing

Aluminum oxide belts effectively cover rough to medium grinding stages.

————————————————————————————————————————————————————————————————————————————————————

Tension, Speed & Load Control

Key Parameters for Belt Stability and Life

Belt stability is highly dependent on machine parameter settings:

- Low tension: Belt tracking issues and slippage

- Excessive tension: Increased risk of belt breakage

- High belt speed: Accelerated abrasive dulling and heat buildup

- Excessive feed pressure: Reduced belt life

Proper tension and speed balance is critical for maximizing belt service life.

————————————————————————————————————————————————————————————————————————————————————

Typical Machines & Applications

- Wide belt sanders (panels, furniture)

- Vertical belt grinders (metal, weld grinding)

- Edge and contour sanding machines

————————————————————————————————————————————————————————————————————————————————————

Grit Range & Recommended Use

- P36 – P60: Heavy grinding and weld removal

- P80 – P120: Medium shaping

- P150 – P240: Surface leveling

- P320 – P400: Pre-finishing sanding

————————————————————————————————————————————————————————————————————————————————————

Splice Type & Belt Performance

Ensuring Smooth Belt Tracking

- Lap joint: Standard option with controlled cost

- Butt joint: Smoother operation for precision machines

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Sanding Belt Engineering Customization

We offer OEM and ODM customization based on machine type, tension range, belt speed, and workpiece material, including backing, abrasive, joint type, and belt dimensions.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our Aluminum Oxide Belts

Process Stability and Long-Term Supply Reliability

With proven belt manufacturing expertise, stable splicing technology, and strict quality control, we deliver sanding belts designed for long-term, stable operation.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

- Verify machine tension before installation

- Run-in new belts at low load

- Store in dry, light-protected conditions