Nonwoven Sanding Belts

- Home

- Nonwoven Sanding Belts

Categories

Nonwoven Sanding Belts

Product Overview

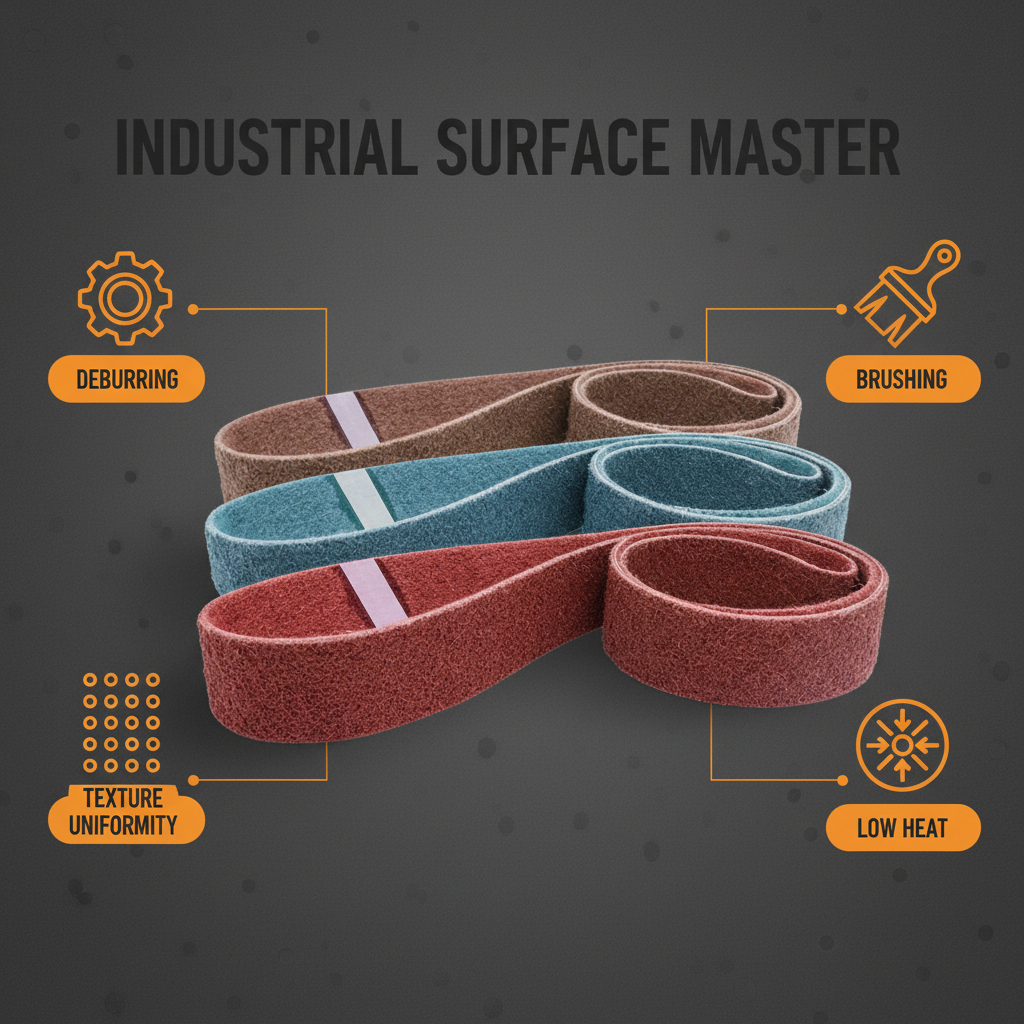

Surface Conditioning Belts for Deburring, Blending and Finishing

The open-web structure of nonwoven belts reduces heat buildup and loading, maintaining consistent surface finishes during extended operation.

The finishing result depends more on fiber-abrasive interaction than aggressive grain cutting.

Product Description

Technical Specifications

|

Item |

Specification |

| Material |

Non-woven fiber impregnated with abrasive |

|

Grade |

Coarse / Medium / Fine (C / M / F) |

| Abrasive Type |

Aluminum Oxide / Silicon Carbide |

|

Backing |

Scrim-reinforced / Light-duty backing / None |

| Joint Type |

Butt Joint |

|

Dimensions |

Custom Sizes Available |

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Non-Cutting Belts for Controlled Surface Treatment

Nonwoven sanding belts are surface conditioning abrasives based on an open fiber web structure, primarily used for deburring, edge radiusing, blending, and surface texturing rather than heavy stock removal.

————————————————————————————————————————————————————————————————————————————————————

Nonwoven Structure & Grade Selection

Matching Aggressiveness to Finishing Requirements

- Coarse grade: Deburring and weld blending

- Medium grade: Surface blending and scratch refinement

- Fine / Very Fine grade: Decorative and final finishing

————————————————————————————————————————————————————————————————————————————————————

Non-Cutting Process Logic

How Nonwoven Belts Work

Nonwoven belts condition surfaces through multi-point, low-pressure contact, refining rather than cutting the workpiece while preserving dimensional accuracy.

————————————————————————————————————————————————————————————————————————————————————

Machine, Tension & Operating Parameters

Stable Performance Under Controlled Conditions

- Recommended medium to low belt tension

- Moderate belt speed is sufficient

- Avoid excessive feed pressure

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison with Coated Abrasive Belts

|

Comparison |

Nonwoven Belts | Coated Abrasive Belts |

| Process | Surface conditioning |

Cutting |

|

Heat control |

Excellent | Moderate |

| Finish consistency | ★★★★★ |

★★★ |

|

Material removal |

Minimal | Significant |

| Dimensional impact | Very low |

Higher |

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

- Stainless steel brushing and decorative finishing

- Metal deburring and edge radiusing

- Surface uniformity treatment for industrial components

————————————————————————————————————————————————————————————————————————————————————

Grade vs Grit Equivalency

Understanding Finishing Levels

- Coarse: approx. P80 – P120

- Medium: approx. P180 – P240

- Fine: approx. P320 – P400

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Surface Conditioning Belt Customization

We offer OEM and ODM customization for nonwoven density, abrasive type, grade combination, and belt dimensions based on surface finish requirements.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our Nonwoven Sanding Belts

Consistent Finish, Low Heat and Process Control

With controlled fiber structure and proven manufacturing processes, we deliver predictable, low-risk surface conditioning solutions.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

- Avoid excessive pressure

- Replace based on finish consistency

- Store in dry conditions