Heavy Paper Backing Sanding Belts

- Home

- Heavy Paper Backing Sanding Belts

Categories

Heavy Paper Backing Sanding Belts

Flatness-Driven Wide Belt Solutions for Panel Sanding

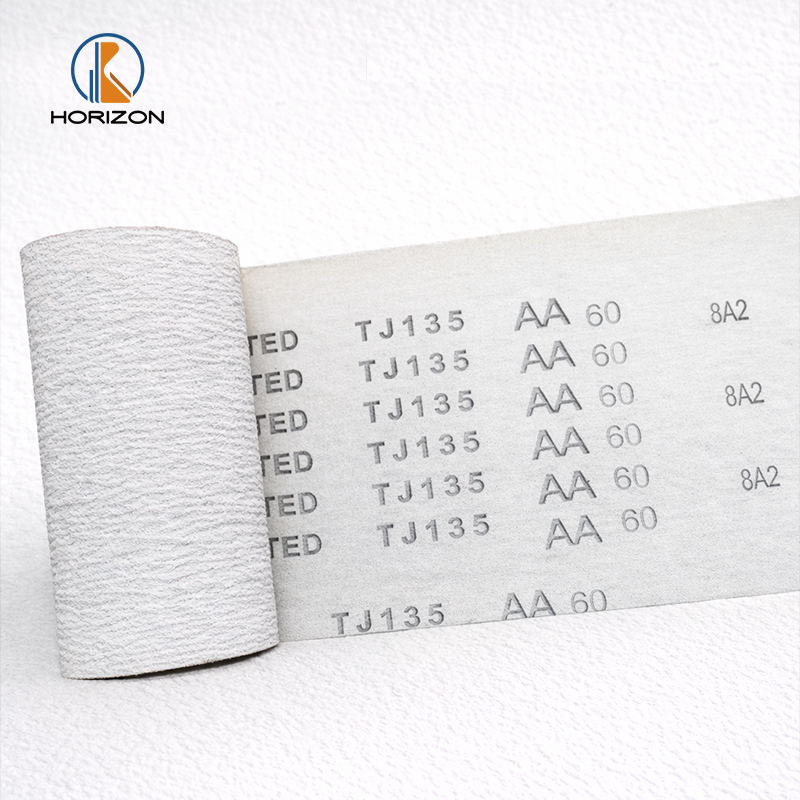

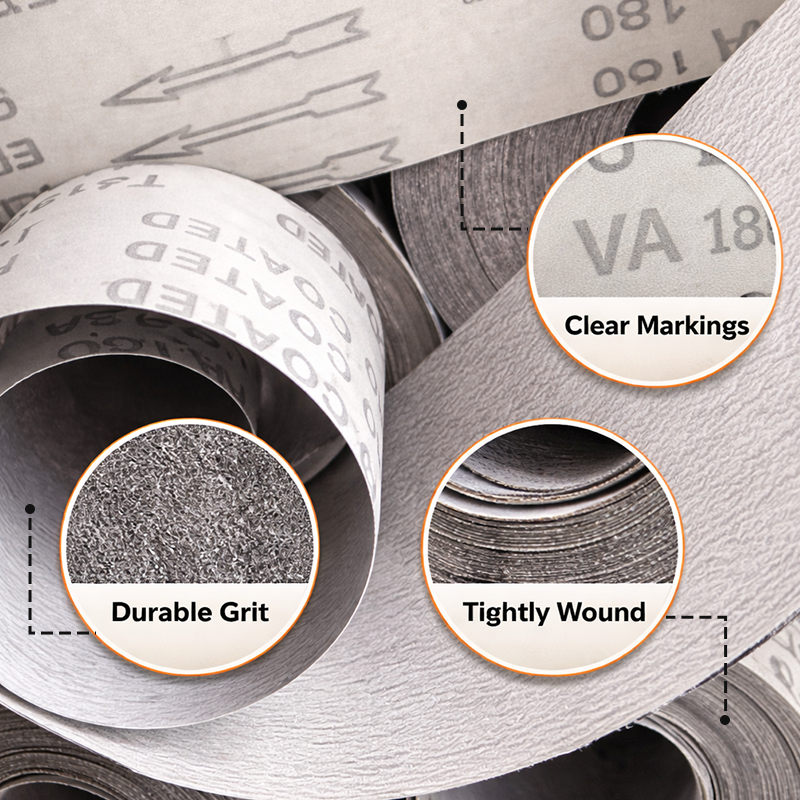

Heavy paper belts use reinforced thick paper backing combined with uniform abrasive coating, maintaining stable geometry during wide belt operation.

Their predictable wear pattern and consistent scratch formation make them ideal for initial and intermediate sanding stages.

Product Description

Product Positioning

Flatness-Oriented Belts for Wide Belt Sanding Systems

Heavy paper backing sanding belts are positioned as flatness-oriented abrasives for wide belt sanding systems.

Rather than extreme tensile strength or aggressive cutting, they focus on stable contact and surface consistency across large sanding areas.

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

|

Item |

English |

| Abrasive |

Aluminum Oxide / Silicon Carbide |

|

Backing |

Heavy-duty paper backing (E-wt / F-wt / G-wt) |

| Grit Range |

P40–P240 |

|

Joint Type |

Butt Joint |

| Bonding |

Full Resin Bond |

|

Dimensions |

Custom Sizes Available |

————————————————————————————————————————————————————————————————————————————————————

Processing Logic

Why Paper Backing Works Better for Flat Panels

In wide belt sanding, surface quality depends more on contact consistency than peak cutting force.

Heavy paper backing creates a stable contact interface, minimizing waviness, chatter marks, and localized over-cutting.

————————————————————————————————————————————————————————————————————————————————————

Backing Structure & Performance Limits

Knowing When to Use—and When Not to Use

- High flatness with low elasticity

- Not suitable for high-tension or heavy impact grinding

- Best for continuous, stable feed applications

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility & Operating Conditions

- Machine type: Wide belt sanders

- Tension range: Medium to low

- Belt speed: Medium to high

- Process type: Continuous sanding

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison with Cloth Belts

|

Comparison |

Heavy Paper Belts | Cloth Belts |

| Flatness | ★★★★★ |

★★★★ |

|

Contact consistency |

★★★★★ | ★★★★ |

| Tension resistance | Medium |

High |

|

Typical use |

Panel sanding | General grinding |

| Cost efficiency | High |

Medium |

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

- Engineered and solid wood panels

- Furniture manufacturing lines

- Flooring, doors, decorative panels

————————————————————————————————————————————————————————————————————————————————————

Grit Range & Recommended Use

- P40–P80: Initial leveling

- P100–P150: Intermediate shaping

- P180–P240: Surface uniforming and pre-finishing

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Panel Sanding-Focused Customization

OEM and ODM customization is available based on wide belt sander specifications, panel materials, and production throughput.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Us

Consistency Comes from Manufacturing Control

As a direct manufacturer, we control paper backing strength, coating uniformity, and batch consistency to ensure reliable performance in production environments.

————————————————————————————————————————————————————————————————————————————————————

Usage & Storage Recommendations

- Ensure correct splice orientation before use

- Avoid excessive tension

- Remove belts during extended downtime

- Store in a dry, temperature-controlled environment