Backing Pads&Grinding Pads

- Главная

- Backing Pads&Grinding Pads

Категории

Backing Pads&Grinding Pads

Обзор продукта

Backing Pad + Interface = Controlled Contact, Secure Attachment and Better Dust Management

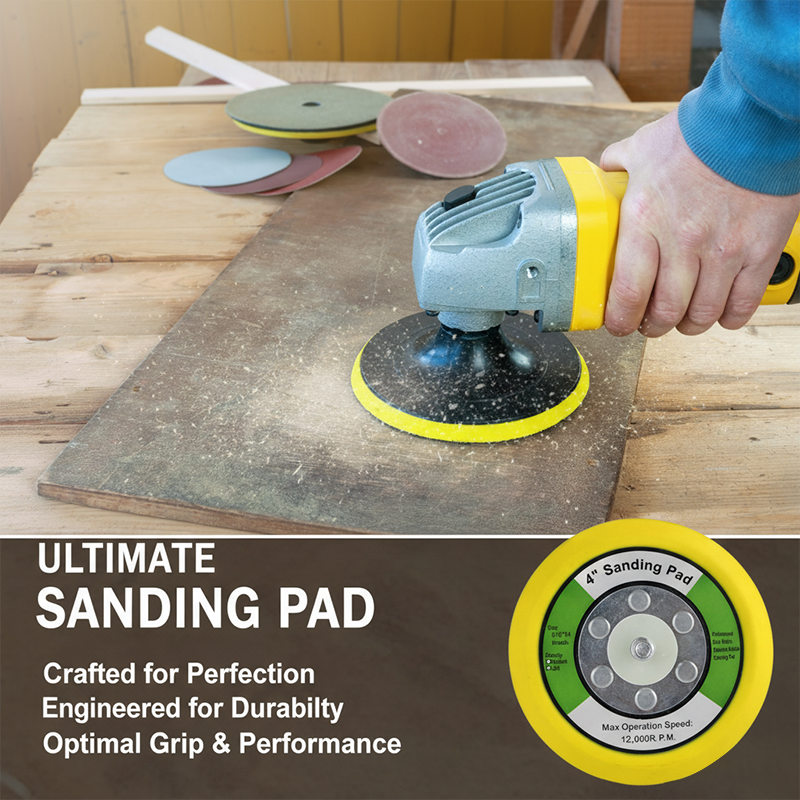

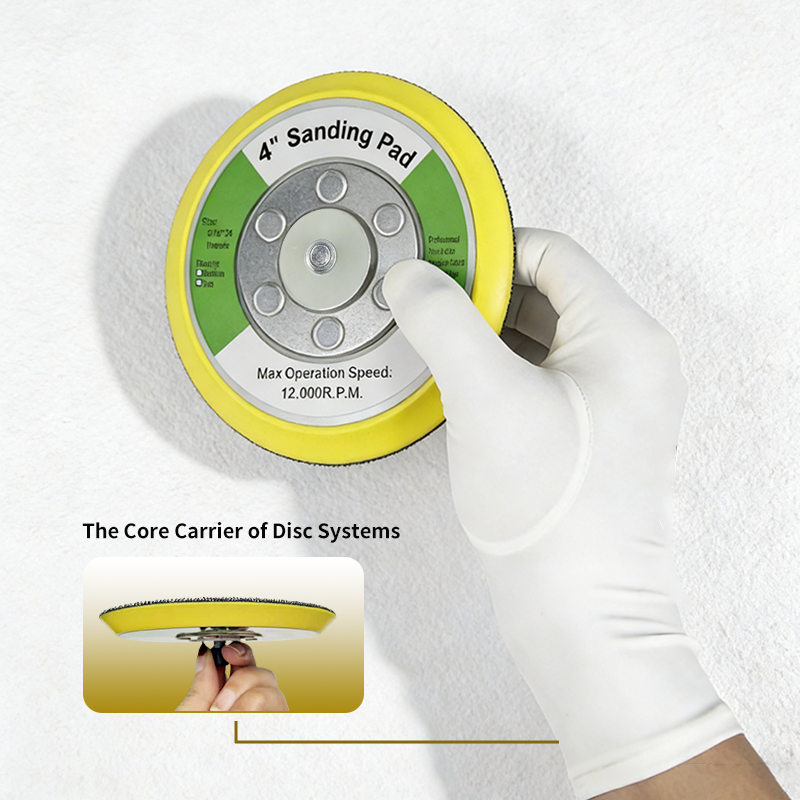

The “Carrier Component” of Disc Systems—Controls Cut, Finish, Vibration & Dust Extraction

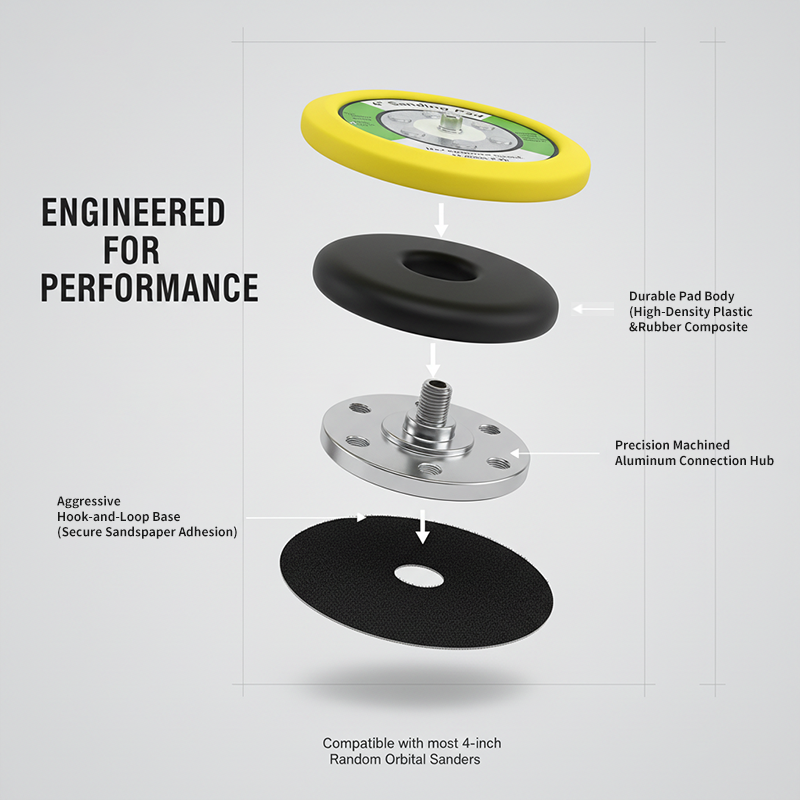

Backing pads typically consist of a pad body (plastic/rubber composite), center mount (thread/quick-change), and attachment face (hook & loop or PSA base), often with multi-hole dust channels.

They transmit rotation and pressure to the abrasive and the workpiece in a controlled way:

- Hardness governs aggressiveness and edge safety;

- Flatness/concentricity govern vibration and scratch consistency;

- Hole pattern and channels govern dust extraction and loading behavior.

Описание продукта

Позиционирование продукта

The Core Carrier of Disc Systems—Defines Stability and Finish Consistency

Backing pads are system-level carriers for disc consumables (sandpaper discs, mesh discs, nonwoven discs, sponge discs, etc.). They do not grind directly, but they define pressure distribution, vibration, edge gouging risk, cutting efficiency, scratch uniformity, and dust extraction performance.

In production and cosmetic finishing, backing pads are a “hidden determinant”—a mismatched pad can cause wobble, streaking, edge burn-through, loading, and inconsistent disc life even with premium abrasives.

————————————————————————————————————————————————————————————————————————————————————

Технические характеристики

Match Diameter, Mount, Hardness and Hole Pattern to Your Sander System

|

Параметр |

Спецификация |

| Тип продукта |

Backing pads / Sanding pad holders |

|

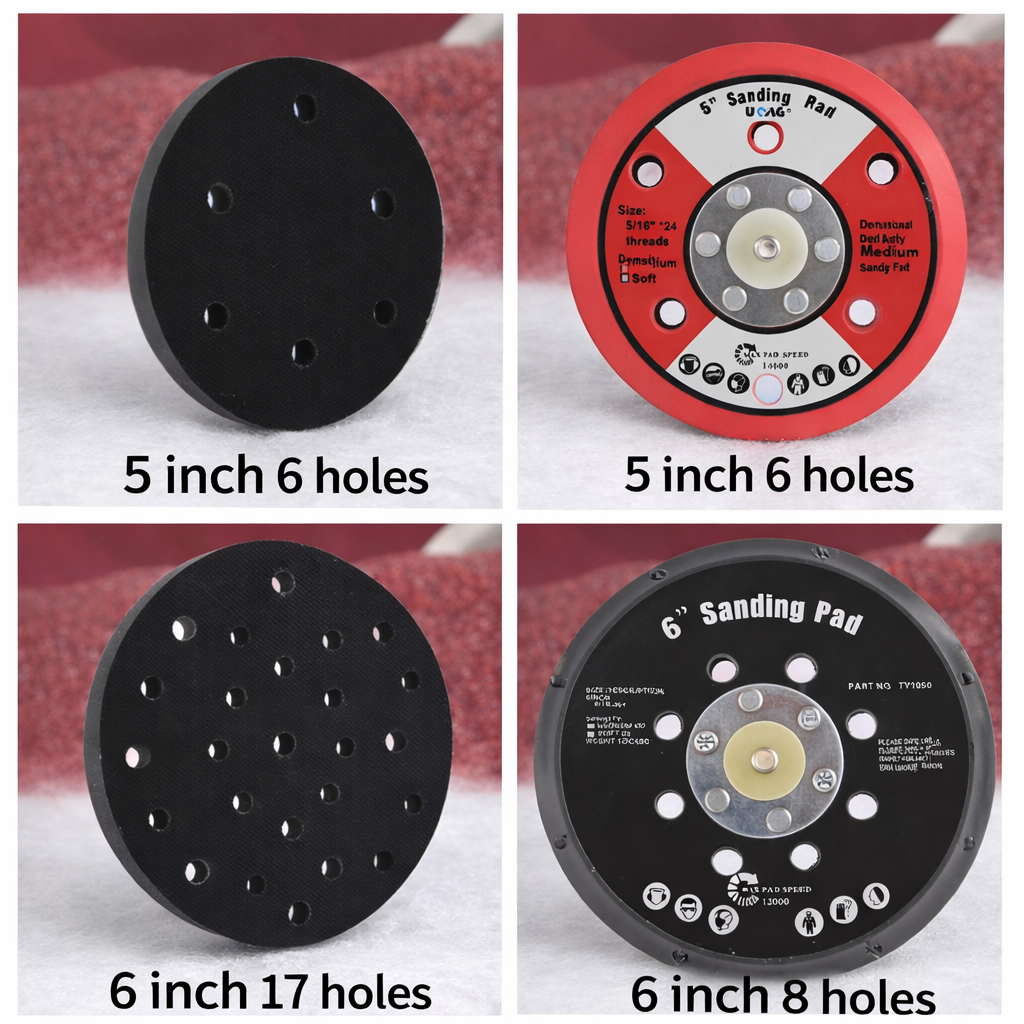

Диаметр |

3″ / 4″ / 5″ / 6″ / 7″ (75–180 mm)(Extendable) |

| Тип крепления |

M6 / M8 / 5/16″-24, etc.(Threaded) |

|

Face Type |

Hook & Loop (Velcro) / PSA (Vinyl) base(Optional) |

| Hardness |

Soft / Medium / Hard (Customizable) |

|

Hole System |

Non-hole / Multi-hole / Custom brand patterns |

| Материал |

Plastic-rubber composite/PU options |

|

Precision |

High-precision balance & concentricity control |

| Макс. об/мин (Max RPM) |

Rated per spec (Never overspeed) |

————————————————————————————————————————————————————————————————————————————————————

Key Features

Hardness Grading, Flatness, Balance and Dust Path Design

- Hardness grading: soft pads conform and protect edges; hard pads cut more directly and help flatten; medium is general-purpose.

- Flatness/concentricity: reduce vibration and streaking, critical for cosmetic and fine-grit work.

- Hole/channel design: matching dust extraction improves life and cleanliness while reducing loading.

- Attachment reliability: durable hook face and bonding prevent disc slippage and uneven wear.

————————————————————————————————————————————————————————————————————————————————————

Логика обработки

The Pad “Shapes” Pressure Distribution—Which Shapes Your Result

Think of a backing pad as a pressure and contact geometry controller:

- Hard pads concentrate pressure on a stable plane for stronger cutting/flattening but are more edge-sensitive.

- Soft pads spread pressure and buffer irregularities for contour following and edge safety with reduced aggressiveness.

- Dust holes remove debris from the contact zone, reducing heat, loading, and random scratching from “dust cushioning.”

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility

Orbit Size, Mount Thread and Dust System Must Match

- Оборудование: random orbital/orbital sanders, some polishers (mount standard dependent)

- Обязательно: diameter, mount (M6/M8/5/16″-24, etc.), orbit size, and RPM rating

- Dust system alignment: hole pattern must align with the disc and machine extraction path—otherwise extraction efficiency drops sharply

————————————————————————————————————————————————————————————————————————————————————

Инженерное сравнение

Soft vs Medium vs Hard Backing Pads—Choose by Defect Level and Surface Geometry

|

Сравнение |

Soft | Средний | Hard |

| Contour/edge safety | ★★★★★ | ★★★★ |

★★★ |

|

Flattening/productivity |

★★★ | ★★★★ | ★★★★★ |

| Cosmetic consistency | ★★★★ | ★★★★★ |

★★★★ |

|

«Прощаемость» (устойчивость к ошибкам техники) |

Высокая | Med–High | Средний |

| Typical pairing | sponge discs, fine grit | general discs, nonwoven |

coarse grit, defect leveling |

————————————————————————————————————————————————————————————————————————————————————

Типовые применения и отрасли

Anywhere Disc Sanding Requires Consistency and Dust Control

- Автоперекраска: filler/primer sanding with dust extraction systems

- Дерево/мебель: large-area finishing and edge transition control

- Cosmetic metal finishing: refinement and streak control

- Industrial manufacturing: standardized stations for batch consistency and reduced rework

————————————————————————————————————————————————————————————————————————————————————

Диапазон и рекомендуемое применение

Quick Selection by Process Stage

- Defect leveling/flattening: harder pad + coarse paper discs (ensure extraction)

- General finishing/unifying: medium pad + common grit paper or nonwoven discs

- Contours/edges/final pre-paint: soft pad + sponge discs/fine paper/mesh discs

- High dust/loading materials: multi-hole pad + mesh discs or matched hole patterns

————————————————————————————————————————————————————————————————————————————————————

Customization (OEM & ODM)

Mount Standards, Hole Patterns and Private Label Programs

OEM/ODM:

diameter/thickness, hardness grading, mount standards (thread/quick-change), hole patterns (universal/brand/no-hole), hook face material and durability grades, body materials/colors, packaging and private label. We can engineer system-matched solutions across mesh/paper/nonwoven/sponge disc families.

————————————————————————————————————————————————————————————————————————————————————

Почему выбирают нас

System-Level Reliability: Balance + Flatness + Hole Alignment

Backing pads create system stability:

concentricity and balance affect vibration/streaking, flatness affects contact consistency, and hole alignment affects extraction and disc life. We provide machine-and-consumable matched solutions to reduce wobble, uneven wear, loading, and rework—improving station repeatability.

————————————————————————————————————————————————————————————————————————————————————

Рекомендации по использованию и хранению

Safe Mounting and Clean Interfaces Preserve Finish Quality

- Verify mount engagement (thread/quick-change), ensure pad is not cracked/warped (never overspeed)

- Keep hook face clean—dust build-up reduces holding power and causes wobble/uneven wear

- Align hole patterns to create a continuous extraction path

- Store dry and shaded; avoid compression/warping; store flat for long periods