Керамические шлифовальные ленты (керамический корунд)

- Главная

- Керамические шлифовальные ленты (керамический корунд)

Категории

Керамические шлифовальные ленты (керамический корунд)

Премиальные самозатачивающиеся ленты для автоматизированного и высокопроизводительного шлифования

Керамический абразив имеет равномерную микрокристаллическую структуру, которая в процессе шлифования постоянно и предсказуемо формирует новые острые режущие кромки, обеспечивая эффект непрерывного самозатачивания.

По сравнению с традиционными абразивами керамические ленты дольше сохраняют режущую способность и имеют более стабильную кривую износа.

Описание продукта

Керамические шлифовальные ленты (керамический корунд)

Премиальные самозатачивающиеся ленты для автоматизированного и высокопроизводительного шлифования

————————————————————————————————————————————————————————————————————————————————————

Технические характеристики

|

Параметр |

Спецификация |

| Абразив |

Абразив: керамический корунд (премиум) |

|

Основа |

Основа: тяжёлая полиэстеровая ткань Y-weight (класс Y) |

| Диапазон зернистости |

P24 – P150 |

|

Тип стыка (соединения) |

Тип стыка: встык / усиленный стык |

| Связка |

Связка: полная смоляная (resin over resin) |

|

Размеры |

Размеры: на заказ по запросу |

————————————————————————————————————————————————————————————————————————————————————

Позиционирование продукта

Топовый уровень лент для автоматизированных линий

Керамические шлифовальные ленты — это премиальные промышленные ленты для высокой производительности, стабильной работы и непрерывных автоматизированных процессов. Они идеально подходят для задач, где критичны максимальный съём и повторяемость результата.

————————————————————————————————————————————————————————————————————————————————————

Обзор продукта

Микрокристаллический абразив и непрерывно «острый» рез

Керамический абразив имеет равномерную микрокристаллическую структуру, которая в процессе шлифования постоянно и предсказуемо формирует новые острые режущие кромки, обеспечивая эффект непрерывного самозатачивания.

По сравнению с традиционными абразивами керамические ленты дольше сохраняют режущую способность и имеют более стабильную кривую износа.

————————————————————————————————————————————————————————————————————————————————————

Сравнение механизма самозатачивания

Инженерные различия: керамика vs циркониевый корунд (zirconia)

- Керамический абразив: контролируемое микротрещинообразование и стабильное самозатачивание

- Абразив zirconia: «блочное» разрушение, для самозатачивания требуется высокий прижим

Керамические ленты сохраняют «остроту» при средних и высоких нагрузках, тогда как ленты zirconia сильнее зависят от режима с высоким прижимом.

————————————————————————————————————————————————————————————————————————————————————

Совместимость с автоматизацией и производственными линиями

Разработано для стабильности, скорости и снижения простоев

Керамические ленты оптимальны для автоматизированных и безлюдных линий: стабильный съём заметно снижает частоту замены ленты и повышает общую эффективность оборудования.

- Совместимо с роботизированными шлифсистемами

- Подходит для многопозиционных непрерывных линий шлифования

- Разработано для высокопроизводительного промышленного выпуска

————————————————————————————————————————————————————————————————————————————————————

Основа, натяжение и работа на высокой скорости

Конструкционная стабильность на промышленных скоростях

Тканевая основа Y-weight (класс Y): Предпочтительно для высокого натяжения и высокой скорости (в исходнике нет подлежащего)

- Сохраняет стабильность размеров при высокой скорости ленты

- Прочность стыка критична для автоматизированной работы

————————————————————————————————————————————————————————————————————————————————————

Технологический процесс и производительность

Максимизация производительности и качества поверхности

- Высокий съём материала сокращает число операций

- Более стабильное качество поверхности

- Снижение совокупной себестоимости на деталь

————————————————————————————————————————————————————————————————————————————————————

Инженерное сравнение с лентами zirconia

|

Сравнение |

Керамические ленты | Ленты zirconia |

| Самозатачивание | Непрерывная микрофрагментация |

«Блочное» разрушение |

|

Требуемая нагрузка |

Средняя–высокая | Высокая |

| Срок службы | Очень большой |

Большой |

|

Пригодность для автоматизации |

★★★★★ | ★★★★ |

| Стоимость | Выше |

Средний |

————————————————————————————————————————————————————————————————————————————————————

Типовые применения и отрасли

- Автоматизированные линии металлообработки

- Нержавеющая сталь и высоколегированные материалы

- Промышленные детали с высокими требованиями к повторяемости

————————————————————————————————————————————————————————————————————————————————————

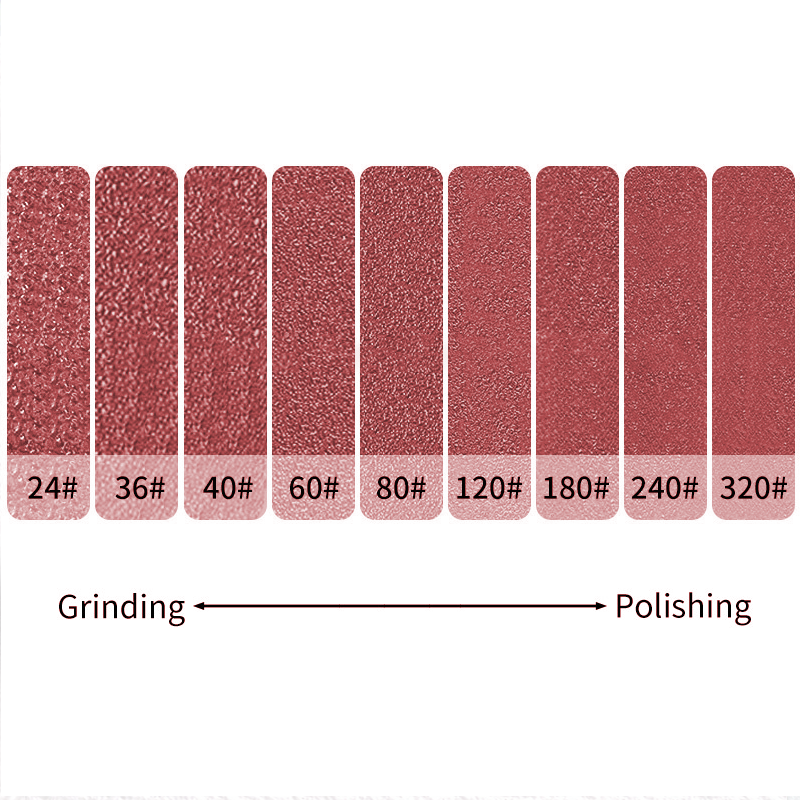

Диапазон зернистости и рекомендации по применению

- P24 – P36: Грубая обдирка и удаление сварного усиления

- P40 – P80: Высокоэффективный съём материала (в исходнике нет подлежащего)

- P100 – P150: Контролируемое формирование и финишная доводка (в исходнике нет подлежащего)

————————————————————————————————————————————————————————————————————————————————————

Возможности OEM/ODM

Премиальные инженерные решения по шлифлентам

Мы обеспечиваем полный цикл OEM/ODM-кастомизации керамических лент, включая усиленный стык, инженерную настройку основы и валидацию применения для автоматизированных линий.

————————————————————————————————————————————————————————————————————————————————————

Почему выбирают наши керамические шлифовальные ленты

Максимальная производительность для требовательных задач

Благодаря глубокой экспертизе в премиальных абразивах и инженерии лент мы предлагаем керамические решения с исключительной стабильностью, эффективностью и предсказуемостью.

————————————————————————————————————————————————————————————————————————————————————

Рекомендации по использованию и хранению

- В начале эксплуатации работайте при рекомендованной нагрузке (обкатка)

- Убедитесь в правильной ориентации стыка

- Храните в сухих условиях при контролируемой температуре