Конические лепестковые круги

- Главная

- Конические лепестковые круги

Категории

Конические лепестковые круги

Обзор продукта

Лепестковые круги для работы по углам, кромкам и профилям — лучший доступ и контроль

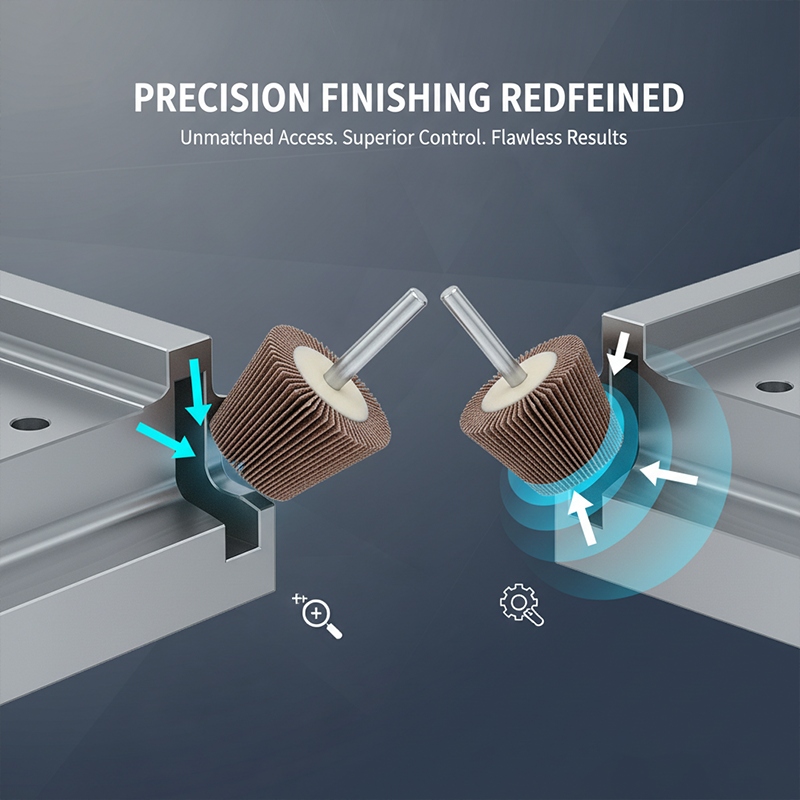

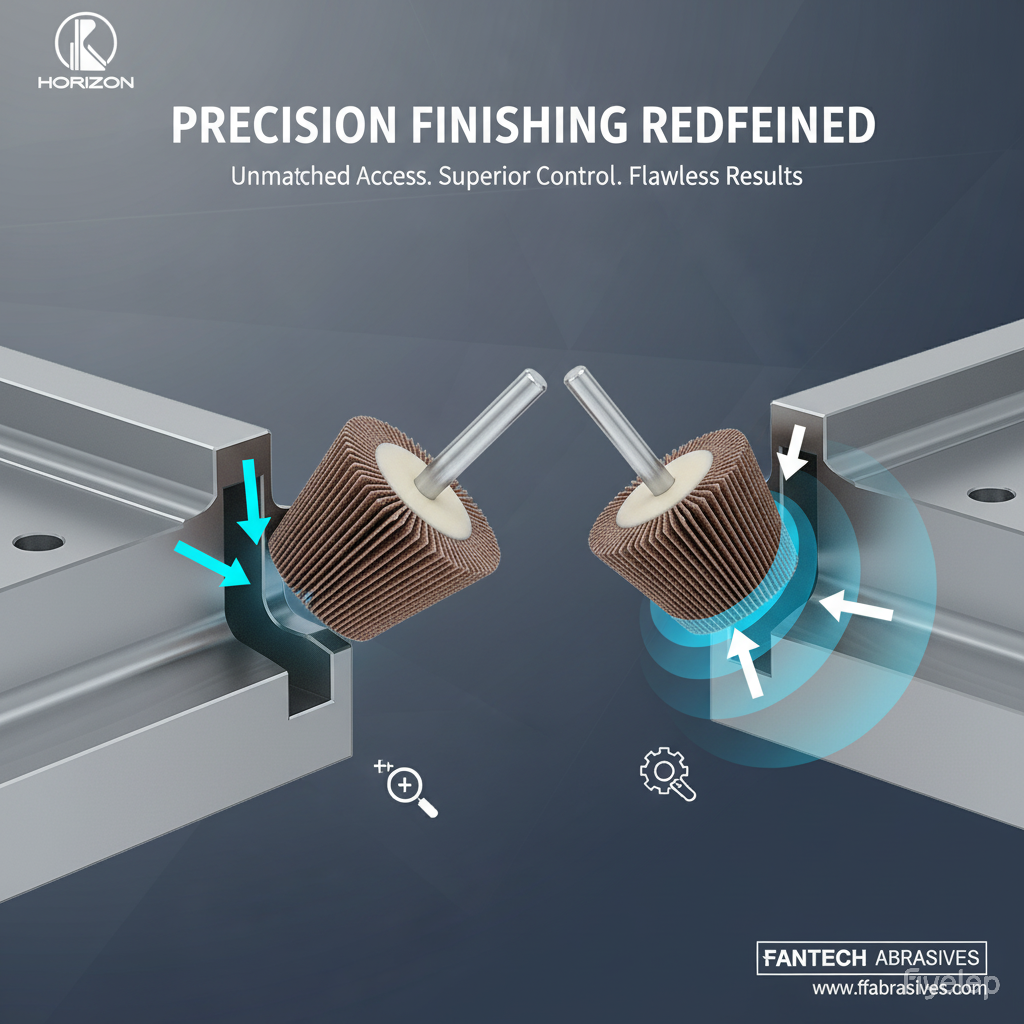

Конические лепестковые круги имеют радиальные абразивные лепестки на коническом (сужающемся) корпусе.Такая геометрия обеспечивает:

- Лучший доступ: узкий носик заходит в углы и кромки профиля;

- Контролируемый контакт: площадь контакта меняется с глубиной «врезания», что помогает лучше управлять съёмом и равномерностью риски.

Поэтому они широко применяются там, где важны обработка углов и стабильный внешний вид.

Описание продукта

Позиционирование продукта

Круги, специально разработанные для углов, наклонных плоскостей и профилей

Конические лепестковые круги позиционируются как финишный инструмент для профилей и углов.По сравнению с цилиндрическими кругами они лучше достают внутренние углы, наклонные поверхности и кромки профиля, а распределение давления получается более управляемым.

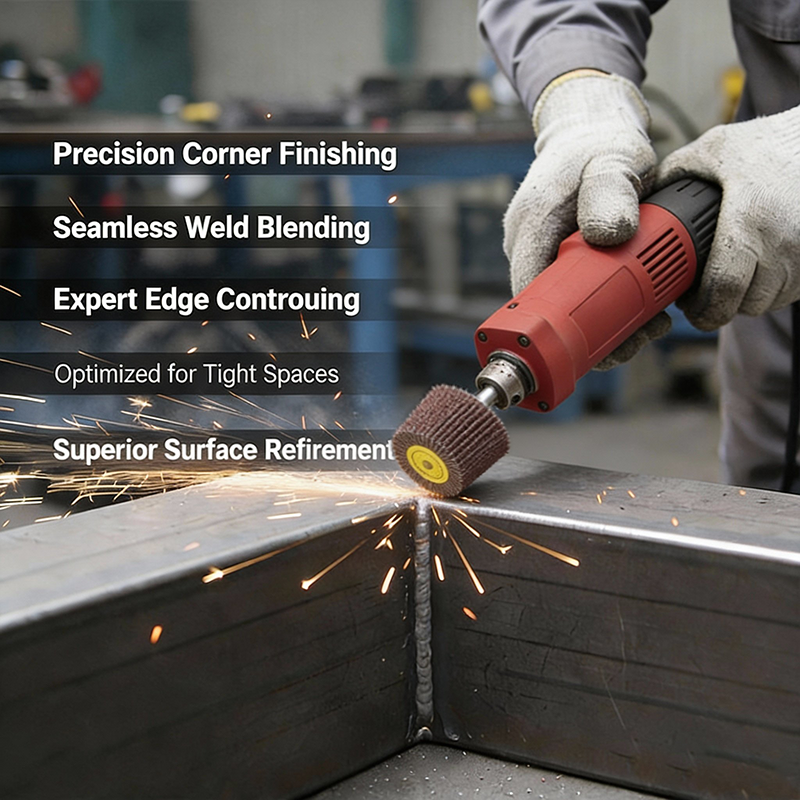

Идеальны для блендинга сварных швов, правки профиля, «сатинирования» кромок и выравнивания текстуры на профильных поверхностях — особенно когда критична обработка углов.

————————————————————————————————————————————————————————————————————————————————————

Технические характеристики

Configurable by Taper Geometry, Bore and Abrasive System

|

Параметр |

Спецификация |

| Тип продукта |

Конические лепестковые круги |

|

Абразив |

Варианты абразива: AO / zirconia / ceramic |

| Конструкция |

Радиальная лепестковая конструкция (коническая) |

|

Наружный диаметр |

Наружный диаметр 1,25″–12″ (30–300 мм) (возможно расширение) |

| Ширина |

Ширина 3/8″–8″ (10–200 мм) (возможно расширение) |

|

Посадочное отверстие |

Посадочное отверстие 1/4″–2″ (на заказ) |

| Диапазон зернистости |

P60–P240 (возможно расширение) |

|

Макс. об/мин (Max RPM) |

Маркировка по размеру и стандарту |

————————————————————————————————————————————————————————————————————————————————————

Логика обработки

Переменная площадь контакта стабилизирует обработку углов/наклонов

При обработке углов часто возникает нестабильный контакт, что приводит к задиркам, глубокой риске или «пересъёму».Конические круги стабилизируют процесс за счёт геометрии:

- При лёгком прижиме работает небольшая зона у носика — для доводки и выравнивания риски;

- При большем прижиме зона контакта расширяется, повышая производительность при сохранении плавного блендинга;

- Идеальны при непрерывном движении вдоль профиля для стабильного направления «сатина» и ровных переходов.

————————————————————————————————————————————————————————————————————————————————————

Конструкция основы и пределы применения

Лучше для углов/профилей, не для выравнивания больших плоскостей

- Плюсы: Отличный доступ к углам, контролируемая обработка по углу, проще выровнять риску

- Ограничения / пределы применения :not for large flat leveling or heavy stock removal; use cylindrical wheels/belts/heavy-duty flap discs for productivity

В зоне носика локальное давление выше: избыточный прижим или задержка увеличивают риск перегрева и неравномерного износа

————————————————————————————————————————————————————————————————————————————————————

Совместимость с оборудованием и условия работы

Круги с посадочным отверстием для финишных станков и профильных постов

- Оборудование: Финишные станки, шлифовально-полировальные машины, специальные оправки (посадка через отверстие)

- Рекомендуемые условия: Средний–низкий прижим, стабильная окружная скорость, непрерывное движение вдоль профиля

- Обязательно: Соответствие отверстия оправке, ширины/конуса и скоростного класса (не превышать Max RPM)

————————————————————————————————————————————————————————————————————————————————————

Инженерное сравнение

Конический vs цилиндрический: доступ и контроль контакта

|

Сравнение |

Конические лепестковые круги | Цилиндрические лепестковые круги |

| Доступ к углам/профилям | ★★★★★ |

★★★ |

|

Контроль по наклонным поверхностям |

★★★★★ | ★★★★ |

| Эффективность на больших плоскостях | ★★★ |

★★★★★ |

|

Стабильность риски |

Отличный | Отличный |

| «Прощаемость» (устойчивость к ошибкам техники) | Средний–высокий |

Высокая |

|

Типичное применение |

углы/профили |

плоскости/наружные диаметры — непрерывный финиш |

————————————————————————————————————————————————————————————————————————————————————

Типовые применения и отрасли

Профильная доводка для металлоконструкций и косметических деталей

- Сатинирование углов и блендинг на поручнях, профилях и декоративных деталях из нержавейки

- Блендинг угловых швов, снятие заусенцев и фаски

- Доводка алюминиевых профилей, правка отверстий/кромок

- Непрерывная обработка внутренних углов, пазов и сложных контуров на фурнитуре/метизах

————————————————————————————————————————————————————————————————————————————————————

Диапазон зернистости и рекомендации по применению

Стратегия зернистости для угловой доводки и блендинга

Типовые рекомендации

- P60–P80: блендинг угловых швов и правка профиля (баланс)

- P100–P120: универсальное сатинирование углов и выравнивание риски (самый распространённый)

- P150–P240: косметическая доводка и исправление переделок на углах/профилях

————————————————————————————————————————————————————————————————————————————————————

Возможности OEM/ODM

Инженерная настройка круга под профильные задачи

OEM/ODM: геометрия конуса (угол/размер носика), стандарты OD/ширины/посадки, плотность и жёсткость лепестков, абразивная система, материал сердечника и класс балансировки, private label/упаковка — инженерно под требования профильной и угловой доводки.

————————————————————————————————————————————————————————————————————————————————————

Почему выбирают нас

Стабильность в углах требует геометрии, балансировки и контроля укладки

Для стабильного результата в углах нужны три контроля: постоянство геометрии конуса, динамическая балансировка и стабильная укладка/связка лепестков.Геометрия и балансировка задают вибрации и направление риски; укладка и связка определяют кривую износа.Мы обеспечиваем стабильность партий, чтобы профильная доводка была воспроизводимой.

————————————————————————————————————————————————————————————————————————————————————

Рекомендации по использованию и хранению

Избегайте перегрева носика — контролируйте прижим и движение

- Не превышайте Max RPM; соблюдайте допустимые обороты и обеспечьте надёжный монтаж с защитой

- По углам работайте со средним–низким прижимом и постоянно перемещайтесь, чтобы избежать перегрева носика и неравномерного износа

- Для косметических деталей переходите по зернистостям ступенчато, чтобы уменьшить глубокую риску и переделки

- Храните в сухом месте в тени; избегайте влаги и сдавливания; после вскрытия повторно герметизируйте упаковку