Лепестковые круги на стекловолоконной основе

- Главная

- Лепестковые круги на стекловолоконной основе

Категории

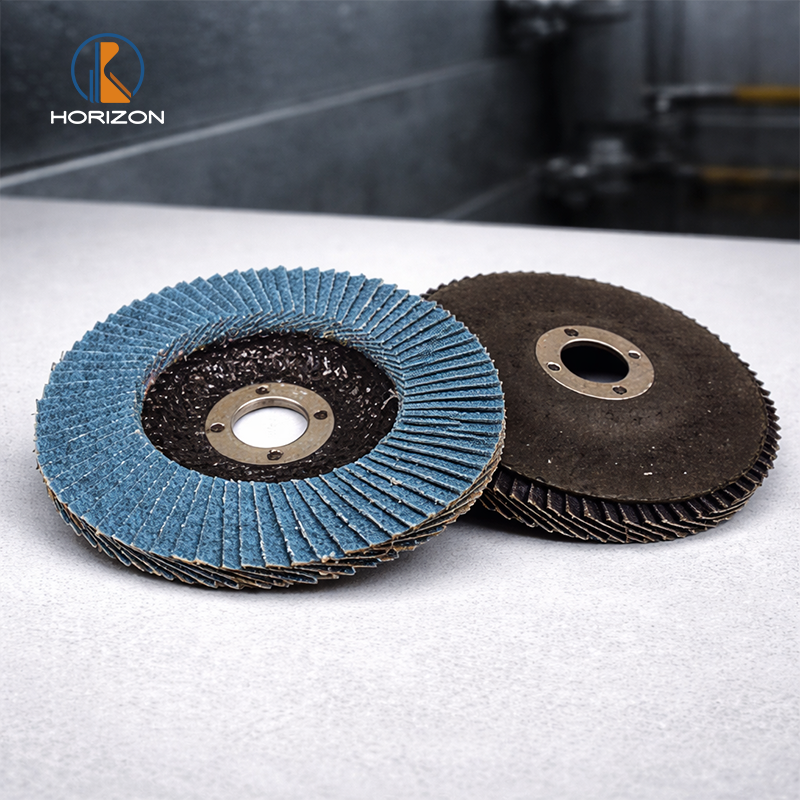

Лепестковые круги на стекловолоконной основе

Лепестковые круги для УШМ: быстрый съём материала и плавный блендинг сварных швов

Несколько лепестков из абразивной ткани (обычно ткань с покрытием AO / zirconia / ceramic) закрепляются на армированной стекловолокном опорной тарелке. В работе лепестки включаются постепенно, обеспечивая более стабильный съём и более плавный блендинг, а стеклопластиковая основа даёт жёсткость и термостойкость.

Описание продукта

Обзор продукта

Жёсткая безопасная основа + непрерывно работающие лепестки

Несколько лепестков из абразивной ткани (обычно ткань с покрытием AO / zirconia / ceramic) закрепляются на армированной стекловолокном опорной тарелке. В работе лепестки включаются постепенно, обеспечивая более стабильный съём и более плавный блендинг, а стеклопластиковая основа даёт жёсткость и термостойкость.

—————————————————————————————————————————————————————————————————————————————————————————-

Технические характеристики

Конфигурации под стандарты рынка

|

Параметр |

Спецификация |

| Тип продукта |

Лепестковые круги на стеклопластиковой основе |

|

Абразив |

Варианты абразива: AO / zirconia / ceramic |

| Форма |

Тип 27 (плоский) / Тип 29 (конический) |

|

Наружный диаметр |

4″ / 4.5″ / 5″ / 7″ |

| Посадочное отверстие |

5/8″ / 7/8″ (в зависимости от рынка) |

|

Диапазон зернистости |

P36–P120 (возможно расширение диапазона) |

| Опорная тарелка (основание) |

Армированная стекловолокном основа |

|

Макс. об/мин (Max RPM) |

Маркировка по размеру и стандарту |

—————————————————————————————————————————————————————————————————————————————————————————-

Логика обработки

3-в-1: съём, выравнивание, блендинг

Преимущества лепестковых кругов:

- Многоточечный съём: нагрузка распределяется, уменьшая риск задиров и «выгрызания»;

- Постоянное обновление контакта: лепестки изнашиваются постепенно, сохраняя стабильное «ощущение реза»;

- Результат зависит от угла: изменяя угол УШМ, можно перейти от интенсивного съёма к блендингу/доводке — идеально для сглаживания швов и переходов по контуру.

—————————————————————————————————————————————————————————————————————————————————————————-

Конструкция основы и пределы применения

Стеклопластик: прочность и термостойкость;

Ограничения: скоростной класс и боковые нагрузки

- Плюсы: стеклопластиковая основа даёт жёсткость, термостойкость и контроль деформации при средних–высоких нагрузках УШМ.

- Ограничения / пределы применения лепестковые круги — это абразивы с покрытием, а не жёсткие шлифкруги; избегайте сильных боковых нагрузок и «поддевания» на острых кромках.

—————————————————————————————————————————————————————————————————————————————————————————-

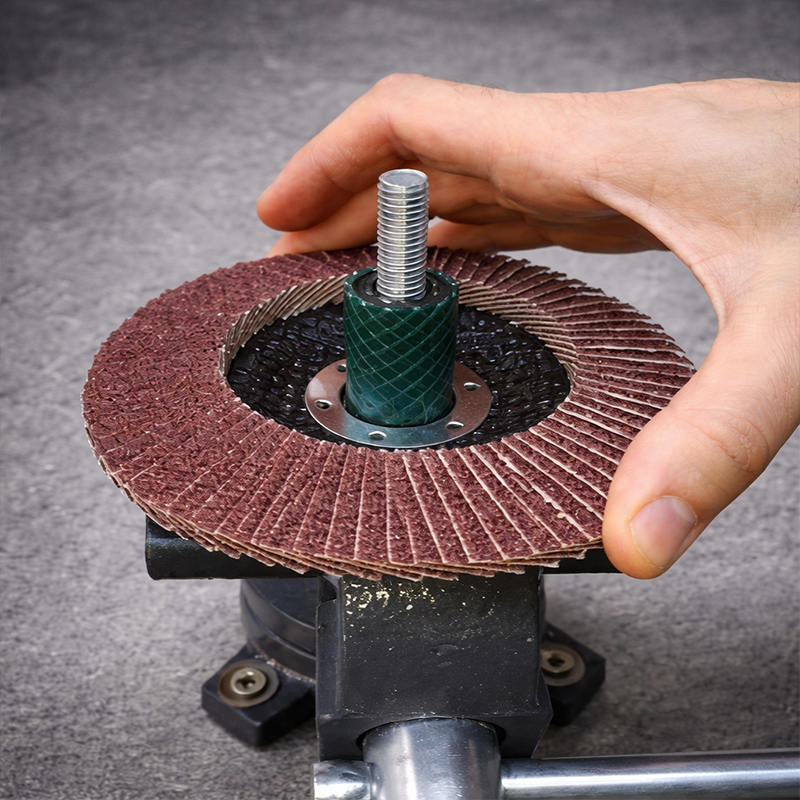

Совместимость с оборудованием и условия работы

УШМ: соответствие по оборотам, защитный кожух и монтаж

- Оборудование: УШМ (электрические/пневматические).

- Обязательно: соответствие диаметра и посадочного отверстия; обороты УШМ ≤ Max RPM круга; правильный кожух и комплект фланцев/прижимных шайб.

Выбор профиля:

- Тип 27 (плоский): лучше для блендинга поверхности и более плоского контакта;

- Тип 29 (конический): лучше для агрессивного съёма, снятия усиления шва и работы по кромкам.

—————————————————————————————————————————————————————————————————————————————————————————-

Инженерное сравнение

Где лепестковые круги относительно шлифкругов и фибровых дисков

|

Сравнение |

Лепестковые круги на стеклопластике | Шлифовальные круги (жёсткие) | Фибровые диски (с опорной тарелкой) |

| Способность к съёму материала | Высокая | Наивысший |

Средний–высокий |

|

Блендинг сварных швов |

Отличный | Среднее (есть риск задиров/выгрызания) | Хорошо (зависит от опорной тарелки) |

| Контроль риски | Хорошо | Слабее |

Хорошо |

|

Риск перегрева (нагрев/побежалость) |

Средний | Средний–высокий | Средний |

| Общая ценность | Высокая | Средний |

Средний–высокий |

—————————————————————————————————————————————————————————————————————————————————————————-

Типовые применения и отрасли

«Рабочая лошадка» для металлообработки

- Снятие усиления шва, блендинг шва, локальная правка

- Удаление заусенцев/снятие фаски на конструкционной стали и листовом металле

- Удаление ржавчины/окалины и очистка старой краски

- Обработка нержавейки (лучше более мелкая зернистость и контролируемый угол)

—————————————————————————————————————————————————————————————————————————————————————————-

Диапазон зернистости и рекомендации по применению

От шлифования к блендингу

Типовые рекомендации

- P36–P40: тяжёлый съём, быстрое снятие усиления шва

- P60: универсальный вариант — съём + блендинг (самый популярный)

- P80–P120: уточнение риски и блендинг поверхности

- P150+: лёгкая доводка (в зависимости от материала и требований)

—————————————————————————————————————————————————————————————————————————————————————————-

Возможности OEM/ODM

От спецификаций к инженерии конструкции

OEM/ODM: системы диаметра/посадочного отверстия, Тип 27/29, абразивные системы (AO/ZA/Ceramic), количество лепестков и угол укладки, толщина основы, private label и упаковка, планы короба и маркировка соответствия.

—————————————————————————————————————————————————————————————————————————————————————————-

Почему выбирают нас

Стабильность достигается системным контролем

Реальные отличия — в конструкции: жёсткость основы, угол укладки лепестков и система связки определяют ощущение реза, тепловое поведение и стабильность ресурса. Мы поставляем промышленные расходники со стабильной конструкцией и надёжностью от партии к партии.

—————————————————————————————————————————————————————————————————————————————————————————-

Рекомендации по использованию и хранению

Безопасность и результат зависят от оборотов + угла + прижима

- Всегда сверяйте скоростной класс круга с оборотами УШМ; не превышайте Max RPM; используйте кожух и СИЗ.

- Держите стабильный рабочий угол; не задерживайтесь на одном месте, чтобы снизить перегрев и побежалость.

- Храните в сухом месте вдали от солнца; избегайте влаги и сильного сжатия; после вскрытия повторно герметизируйте упаковку, чтобы исключить пыль и влажность.