Лепестковые круги (чередующиеся лепестки)

- Главная

- Лепестковые круги (чередующиеся лепестки)

Категории

Лепестковые круги (чередующиеся лепестки)

Лепестковые круги для контролируемого финиша, блендинга и обработки поверхности

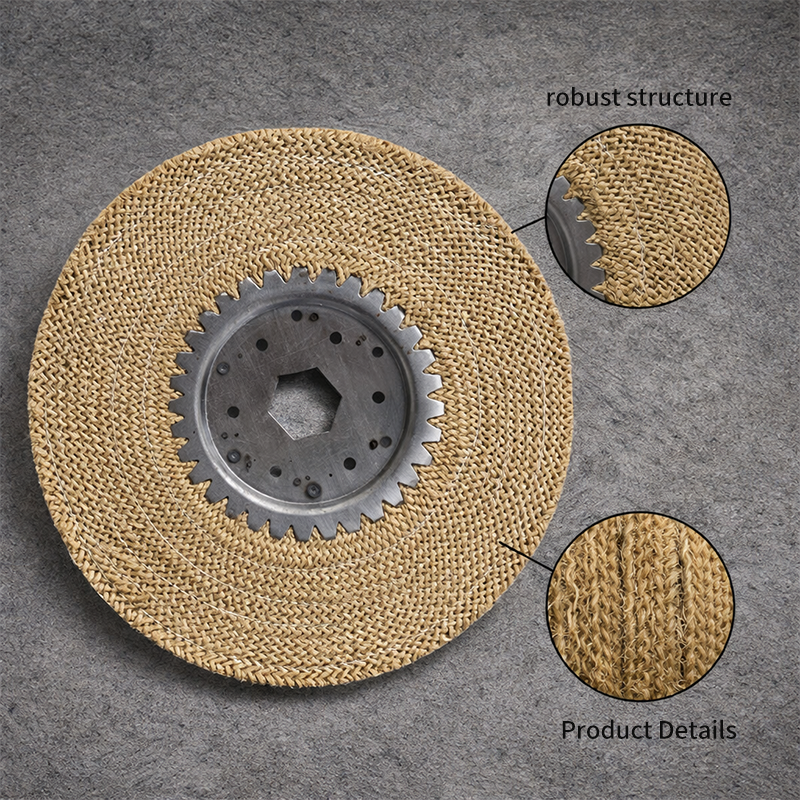

Интерливная (чередующаяся) структура объединяет лепестки из абразивной ткани (для съёма) и нетканый материал (для доводки):

Тканевые лепестки обеспечивают контролируемый съём материала;

Нетканые лепестки снижают нагрев, «смягчают» глубокие риски и выравнивают текстуру поверхности;

Это повышает стабильность финиша и управляемость процесса без добавления дополнительных этапов.

Описание продукта

Позиционирование продукта

Гибридные лепестковые круги: съём + доводка

Интерливные лепестковые круги позиционируются как гибридные круги для УШМ с приоритетом качества поверхности.За счёт чередования лепестков из абразивной ткани и нетканых доводочных лепестков они объединяют съём материала + сглаживание риски + формирование текстуры в одном инструменте.

Идеальны для деталей, где важны единый внешний вид и повторяемая риска (например, нержавейка, алюминий, декоративные элементы): блендинг швов, выравнивание поверхности и лёгкое удаление заусенцев.

—————————————————————————————————————————————————————————————————————————————————————————-

Технические характеристики

Конфигурации под требуемый финиш

|

Параметр |

Спецификация |

| Тип продукта |

Интерливные лепестковые круги (Combi-disc) |

|

Конструкция |

Чередование абразивной ткани и нетканых лепестков |

| Форма |

Тип 27 (плоский) / Тип 29 (конический) |

|

Наружный диаметр |

4″ / 4.5″ / 5″ / 7″ |

| Крепление |

Посадочное отверстие / резьбовая втулка (опционально) |

|

Диапазон зернистости |

P40–P150 (возможно расширение) |

|

Опорная тарелка (основание) |

Основа: стеклопластик/металл (по запросу) |

—————————————————————————————————————————————————————————————————————————————————————————-

Логика обработки

Нетканый «буфер» делает результат более управляемым

Обычные лепестковые круги при высоком прижиме или нестабильном угле могут давать задиры и глубокую риску. Интерливные круги используют нетканый «буфер», чтобы:

- Снижать пик агрессивности и риск задиров;

- Переводить риску из «глубокой и хаотичной» в «более мелкую и равномерную»;

- Улучшать блендинг швов и косметический финиш поверхности.

—————————————————————————————————————————————————————————————————————————————————————————-

Конструкция основы и пределы применения

Ориентировано на поверхность, не на тяжёлый съём

- Плюсы: более равномерный финиш, меньше нагрев, более плавный блендинг

- Ограничения: не для интенсивного съёма и ударных режимов; для тяжёлого съёма выбирайте лепестковые круги на металле/стеклопластике или шлифкруги

- Более «щадяще» для нержавейки, но угол и прижим всё равно нужно контролировать

—————————————————————————————————————————————————————————————————————————————————————————-

Совместимость с оборудованием и условия работы

Настройка УШМ для обработки поверхности

- Оборудование: УШМ (электрическая/пневматическая)

- Рекомендуемые условия: средний–низкий прижим, стабильный угол, постоянное движение

- Цель: внешний вид и повторяемая риска важнее максимального съёма

—————————————————————————————————————————————————————————————————————————————————————————-

Инженерное сравнение

|

Сравнение |

Лепестковые круги (чередующиеся лепестки) | Обычные лепестковые круги | Нетканые круги для обработки поверхности |

| Способность к съёму материала | Средний | Высокая |

Низкая |

|

Блендинг сварных швов |

Отличный | Хорошо (зависит от техники) | Средний |

| Стабильность текстуры | Отличный | Среднее–хорошее |

Отличный |

|

Риск глубокой риски |

Низкая | Средний | Низкая |

| Риск перегрева/побежалости | Низкий–средний | Средний |

Низкая |

—————————————————————————————————————————————————————————————————————————————————————————-

Типовые применения и отрасли

Процессы для нержавейки и косметического финиша

- Блендинг сварных швов и выравнивание поверхности на нержавейке

- Лёгкое удаление заусенцев и косметический финиш алюминиевых деталей

- Скругление кромок и переходы под «сатин/шлифованный» финиш на листовом металле

- Косметические детали: корпуса, поручни, кухонно-санитарная фурнитура

—————————————————————————————————————————————————————————————————————————————————————————-

Диапазон зернистости и рекомендации по применению

Типовая стратегия зернистости для блендинга

Типовые рекомендации

- P40–P60: лёгкий съём + блендинг шва (акцент на производительность)

- P80: универсальный блендинг поверхности (самый распространённый)

- P120–P150: косметическая доводка и смягчение текстуры

—————————————————————————————————————————————————————————————————————————————————————————-

Возможности OEM/ODM

Кастомизация под целевую текстуру

OEM/ODM: доля чередования (ткань/нетканый), плотность/класс нетканого, абразивная система, стандарты диаметра/посадки/резьбы, Тип 27/29, private label и упаковка — инженерно под целевую текстуру и материал.

—————————————————————————————————————————————————————————————————————————————————————————-

Почему выбирают нас

Стабильный внешний вид требует контролируемой конструкции

Повторяемый косметический результат требует контроля конструкции: плотность нетканого, угол укладки и система связки формируют характер риски, тепловое поведение и ресурс диска. Мы проектируем под стабильность партий, чтобы косметический финиш был воспроизводимым.

—————————————————————————————————————————————————————————————————————————————————————————-

Рекомендации по использованию и хранению

Стабильность финиша зависит от угла, прижима и движения

- Работайте со средним–низким прижимом и стабильным углом; не задерживайтесь на месте

- Для косметической нержавейки переходите по зернистостям ступенчато, чтобы снизить переделки

- Храните в сухом месте в тени; влага ухудшает работу нетканого материала

- После вскрытия повторно герметизируйте, чтобы круги оставались чистыми и сухими