Мини лепестковые круги

- Главная

- Мини лепестковые круги

Категории

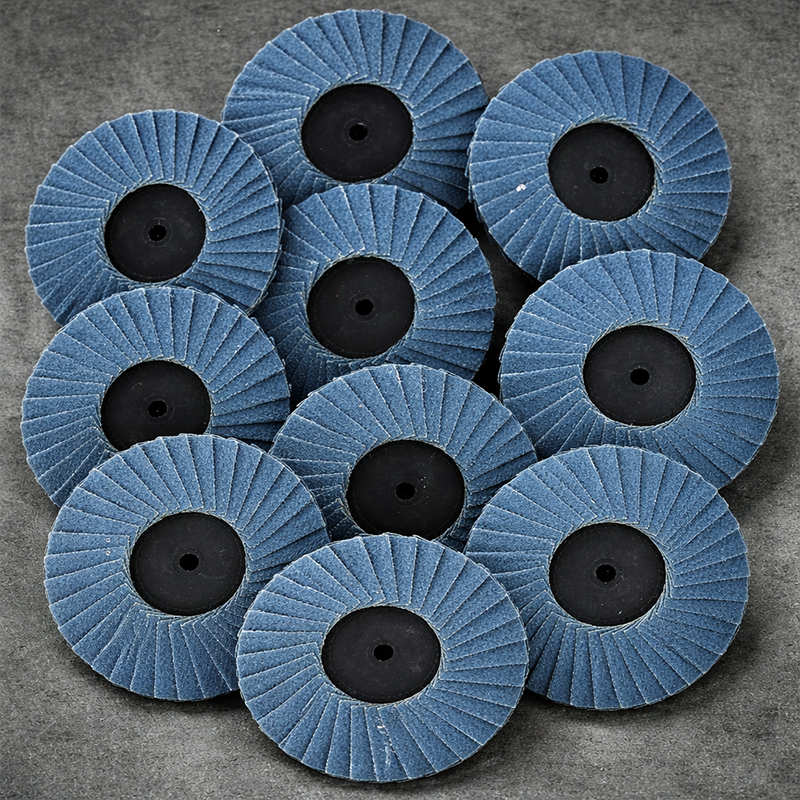

Мини лепестковые круги

Лепестковые круги малого диаметра для точной шлифовки в труднодоступных местах

Мини-лепестковые круги сочетают компактную основу и многослойные абразивные лепестки.Они сохраняют преимущества лепестковых кругов — непрерывный съём и плавный блендинг — при этом улучшают управляемость:

- Лучше подходят к локальным радиусам и кромкам;

- Более подходят для лёгкого съёма и уточнения риски;

- Меньшая площадь контакта снижает риск случайных повреждений и переделок.

Описание продукта

Позиционирование продукта

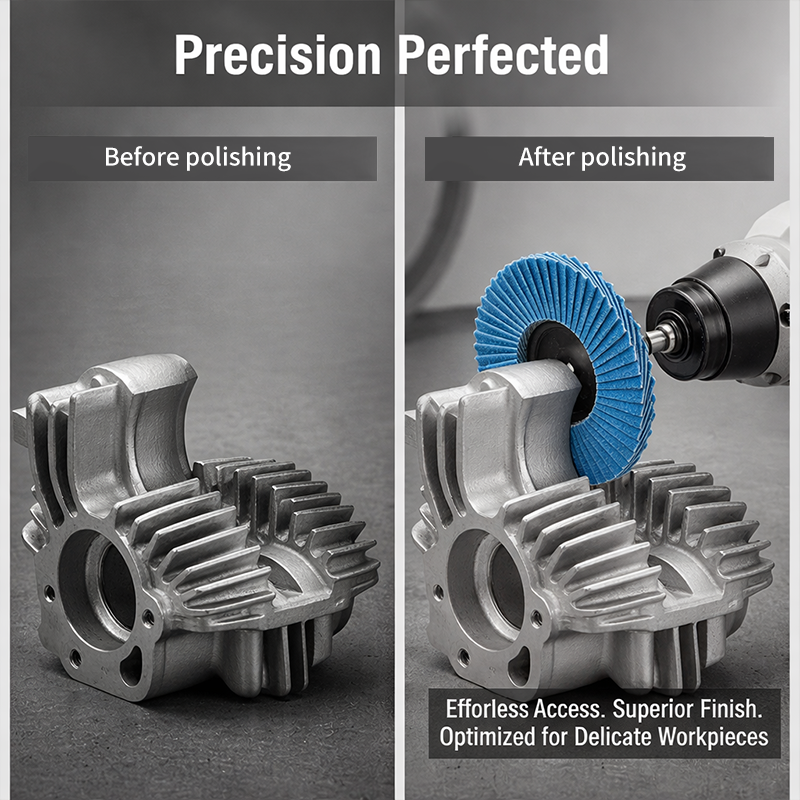

Прецизионные лепестковые круги для тесных зон и детальных работ

Мини-лепестковые круги предназначены для точной шлифовки и блендинга в ограниченном пространстве и дополняют стандартные круги 4″–5″ для детальных операций.

Для внутренних углов, узких кромок, зон вокруг отверстий и точек сварки, где стандартный круг не проходит или может повредить прилегающую поверхность, мини-лепестковый круг даёт более точный съём и блендинг за счёт меньшего «пятна» контакта.

—————————————————————————————————————————————————————————————————————————————————————————-

Технические характеристики

Компактные варианты под разные стандарты инструмента

|

Параметр |

Спецификация |

| Тип продукта |

Мини-лепестковые круги |

|

Абразив |

Варианты абразива: AO / zirconia / ceramic |

| Наружный диаметр |

2″ / 3″ (возможно расширение линейки) |

|

Форма |

Тип 27 (наиболее распространённый) |

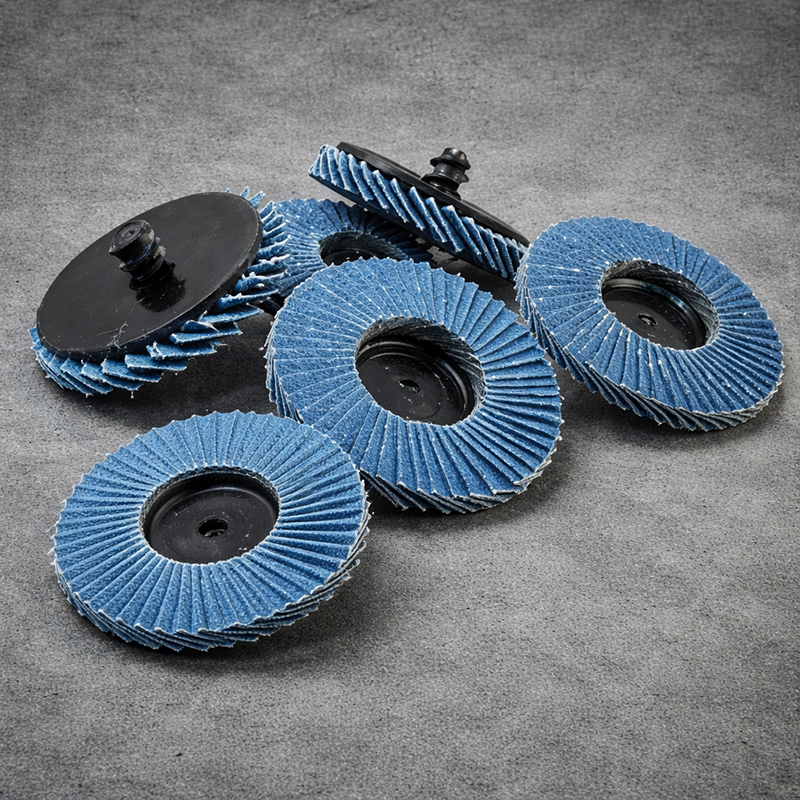

| Крепление |

Посадочное отверстие / резьба (опционально) |

|

Диапазон зернистости |

P36 – P150 |

| Опорная тарелка (основание) |

Основа: стеклопластик/металл (по запросу) |

|

Макс. об/мин (Max RPM) |

Маркировка по размеру и стандарту |

—————————————————————————————————————————————————————————————————————————————————————————-

Логика обработки

Малое пятно контакта + стабильный угол — для точного результата

- Мини-лепестковые круги — не про максимальную агрессию, а про контроль:

- Малая зона контакта концентрирует воздействие для точного съёма;

- Лучше видимость при работе по точкам сварки, кромкам и внутренним углам;

- Идеальны для поэтапной доводки с переходом по зернистостям — от коррекции к блендингу.

—————————————————————————————————————————————————————————————————————————————————————————-

Конструкция основы и пределы применения

Для детальных работ, не замена тяжёлым шлифдискам

- Плюсы: Отличный доступ, высокий контроль, меньший риск повреждений

- Ограничения / пределы применения Не для тяжёлого съёма на больших площадях; для производительности выбирайте стандартные лепестковые круги на стеклопластике/металле

Чрезмерный прижим или задержка на месте всё равно могут вызвать перегрев/следы или задиры — техника важна

—————————————————————————————————————————————————————————————————————————————————————————-

Совместимость с оборудованием и условия работы

Лучше всего для компактных УШМ и участков детальной обработки

- Оборудование: Компактные УШМ, прямые/пневмошлифмашины (в зависимости от крепления)

- Рекомендуемые условия: средний–низкий прижим, стабильный угол, постоянное движение

- Обязательно: Соответствие диаметра, посадки/резьбы и скоростного класса (не превышать Max RPM)

—————————————————————————————————————————————————————————————————————————————————————————-

Инженерное сравнение

Мини vs стандарт: доступ vs производительность

|

Сравнение |

Мини лепестковые круги | Стандартные лепестковые круги (4″–5″) |

| Доступность | ★★★★★ |

★★★ |

|

Контроль деталей |

★★★★★ | ★★★★ |

| Производительность на большой площади | ★★ |

★★★★★ |

|

Риск повредить прилегающую поверхность |

Низкая | Средний |

| Типичное применение | Углы, кромки, локальные зоны | Универсальное шлифование и блендинг |

—————————————————————————————————————————————————————————————————————————————————————————-

Типовые применения и отрасли

Металлообработка в тесных местах и локальная доводка

- Правка точек сварки и локальный блендинг

- Внутренние углы, кромки отверстий, шлифование узких кромок

- Правка кромок и снятие фаски на листовом металле

- Локальное устранение риски на косметических деталях из нержавейки

—————————————————————————————————————————————————————————————————————————————————————————-

Диапазон зернистости и рекомендации по применению

Стратегия зернистости для точных работ

Типовые рекомендации

- P36–P60: Правка точек сварки и лёгкий съём

- P80: универсальный блендинг и выравнивание риски (самый распространённый)

- P120–P150: Косметическая доводка и локальный ремонт

—————————————————————————————————————————————————————————————————————————————————————————-

Возможности OEM/ODM

Кастомизация для детальных работ

OEM/ODM: диаметр и системы посадки/резьбы, абразивные системы, количество лепестков и угол укладки, материал/толщина основы, private label и упаковка, а также наборы для участков детальной обработки и aftermarket-каналов.

—————————————————————————————————————————————————————————————————————————————————————————-

Почему выбирают нас

Стабильная точность требует контроля конструкции

Стабильность мини-кругов сильно зависит от конструкции: жёсткость основы при малом диаметре, равномерность укладки лепестков и система связки определяют «ощущение реза» и разброс ресурса. Мы контролируем конструкцию и процесс, обеспечивая стабильность партий и повторяемый результат в детальных задачах.

—————————————————————————————————————————————————————————————————————————————————————————-

Рекомендации по использованию и хранению

Лучший контроль достигается правильным прижимом и движением

- Работайте со средним–низким прижимом, держите стабильный угол и постоянно перемещайтесь, чтобы избежать перегрева

- Сначала используйте среднюю/крупную зернистость для коррекции, затем более мелкую — для выравнивания риски

- Не превышайте Max RPM; обеспечьте надёжный монтаж и правильную защиту

- Храните в сухом месте в тени; избегайте влаги и сильного сжатия