PSA Sanding Discs

- Home

- PSA Sanding Discs

Categories

PSA Sanding Discs

PSA Sanding Discs (Pressure Sensitive Adhesive Discs)

Strong Adhesion, Flat Contact and Predictable Performance

Our PSA sanding discs use industrial-grade pressure-sensitive adhesive systems that ensure secure attachment while avoiding excessive adhesive thickness that may cause surface waviness.

They are optimized for continuous sanding operations, balancing cutting efficiency, heat dissipation, and attachment stability.

Product Description

PSA Sanding Discs (Pressure Sensitive Adhesive Discs)

Stable Adhesive Sanding Discs for Precision and Flat Surface Finishing

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

|

Item |

Specification |

| Diameter |

4″ / 5″ / 6″ / 7″ (100-180mm) |

|

Abrasive Type |

Aluminum Oxide / Ceramic / Silicon Carbide |

| Grit Range |

P40 – P3000 |

|

Backing |

Paper / Film backing |

| Adhesive Type |

Standard / Heat-resistant PSA |

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Flat-Mount Sanding Discs for Consistent Surface Quality

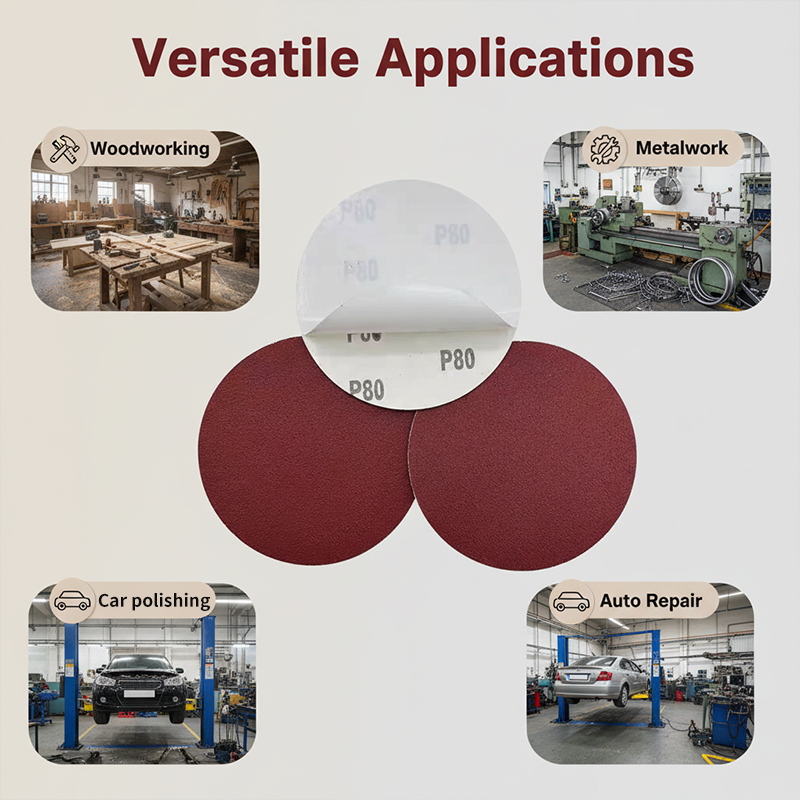

PSA sanding discs are finished abrasive discs that attach directly to the backing pad via pressure-sensitive adhesive. They are designed for applications requiring flat mounting and consistent surface quality, commonly used in woodworking, metal processing, and automotive refinishing.

————————————————————————————————————————————————————————————————————————————————————

Product Overview

Strong Adhesion, Flat Contact and Predictable Performance

Our PSA sanding discs use industrial-grade pressure-sensitive adhesive systems that ensure secure attachment while avoiding excessive adhesive thickness that may cause surface waviness.

They are optimized for continuous sanding operations, balancing cutting efficiency, heat dissipation, and attachment stability.

————————————————————————————————————————————————————————————————————————————————————

Abrasive Grain Selection

Matching Cutting Behavior to Application Needs

Aluminum Oxide

General-purpose abrasive for wood, metal, and standard industrial sanding.

Ceramic Abrasive

Designed for heavy-duty sanding and high material removal rates.

Silicon Carbide

Ideal for fine sanding, coating preparation, and smooth surface finishing.

————————————————————————————————————————————————————————————————————————————————————

PSA Adhesive System & Use Conditions

Adhesion Strength and Temperature Considerations

The performance of PSA sanding discs depends heavily on backing pad condition and operating temperature:

- Backing pads should be clean and flat

- Heat-resistant adhesive is recommended for high-temperature applications

- Repeated removal and reapplication is not recommended

————————————————————————————————————————————————————————————————————————————————————

Grit Selection by Sanding Stage

- P40 – P80: Coarse sanding and rapid stock removal

- P100 – P180: Medium sanding and surface leveling

- P220 – P400: Fine sanding and coating preparation

- Above P600: Fine finishing and surface improvement

————————————————————————————————————————————————————————————————————————————————————

Common Selection Mistakes

Issues Frequently Seen in PSA Disc Applications

Mistake 1:Using PSA Discs for High-Frequency Replacement Tasks

PSA discs are not suitable for frequent disc changes, as repeated removal weakens adhesive performance and contaminates backing pads.

Mistake 2:Neglecting Backing Pad Cleanliness

Dust or adhesive residue on backing pads significantly reduces adhesion and sanding stability.

Mistake 3:Failure to Select Heat-Resistant Adhesive for High-Temp Conditions

Standard adhesive may soften under high-speed or high-pressure conditions, leading to disc detachment.

————————————————————————————————————————————————————————————————————————————————————

PSA vs Velcro Disc Comparison

Selecting the Right Attachment System

|

Comparison |

PSA Discs | Velcro Discs |

| Attachment | Pressure-sensitive adhesive |

Hook & loop |

|

Change frequency |

Low | High |

| Flatness | ★★★★★ |

★★★★ |

|

Reusability |

Not recommended | Recommended |

| Applications | Precision, flat surfaces |

Multi-step sanding |

————————————————————————————————————————————————————————————————————————————————————

Compatible Machines & Applications

- Flat sanding machines

- Orbital sanders

- Woodworking, metalworking, automotive refinishing

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Custom PSA Disc Manufacturing

We provide OEM and ODM customization for adhesive type, disc size, abrasive selection, and packaging to match specific machines and applications.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our PSA Sanding Discs

Flat Contact, Stable Adhesion and Consistent Quality

With proven adhesive control, stable coating processes, and strict quality inspection, we deliver reliable PSA sanding solutions with minimal failure rates.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

- Clean backing pads before use

- Avoid prolonged storage in high temperatures

- Replace discs promptly after removal