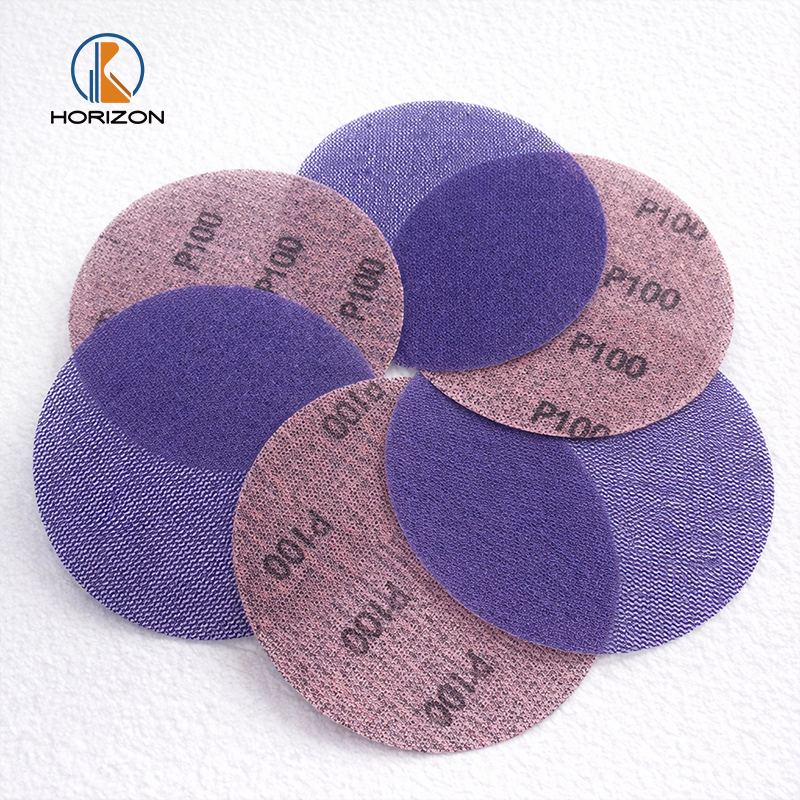

Mesh Sanding Discs/Sanding Net Discs

- Home

- Mesh Sanding Discs/Sanding Net Discs

Categories

Mesh Sanding Discs/Sanding Net Discs

Disc-Based Dust-Control Abrasives for Clean, Efficient Machine Sanding

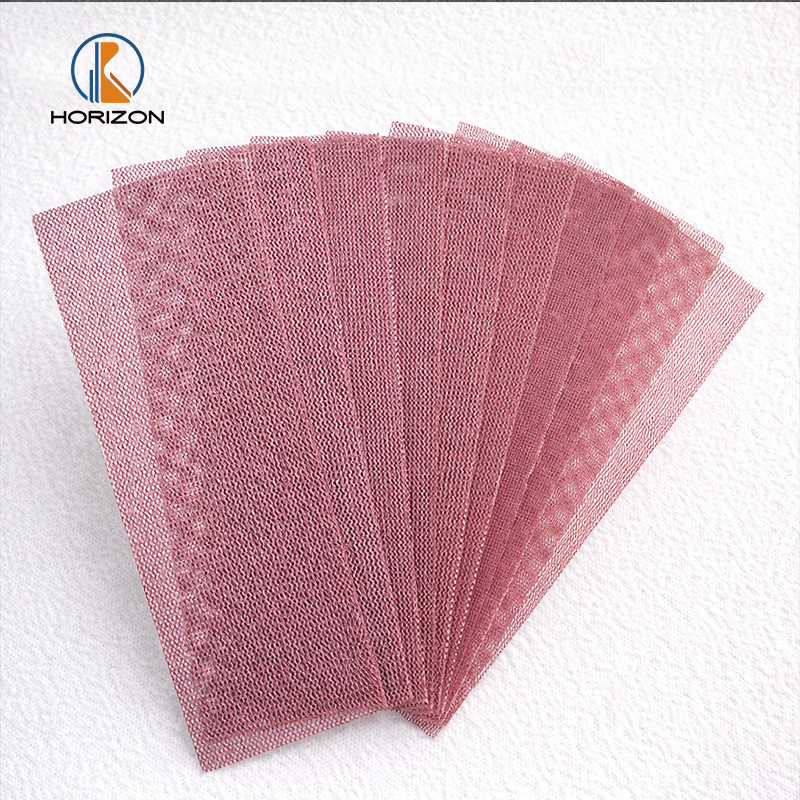

Mesh sanding discs utilize a high-strength open mesh backing with evenly distributed abrasives, allowing dust to pass directly through the disc during sanding.

This design eliminates reliance on fixed hole patterns and delivers full-surface dust extraction without dead zones.

Product Description

Product Positioning

Dust-Control-Focused Discs for Orbital Sanding Systems

Mesh sanding discs are positioned as dust-control-oriented abrasive discs designed for orbital and random orbital sanding systems.

Rather than aggressive cutting, their value lies in cleaner operation, more consistent surface results, and extended abrasive life compared to traditional paper-backed discs.

————————————————————————————————————————————————————————————————————————————————————

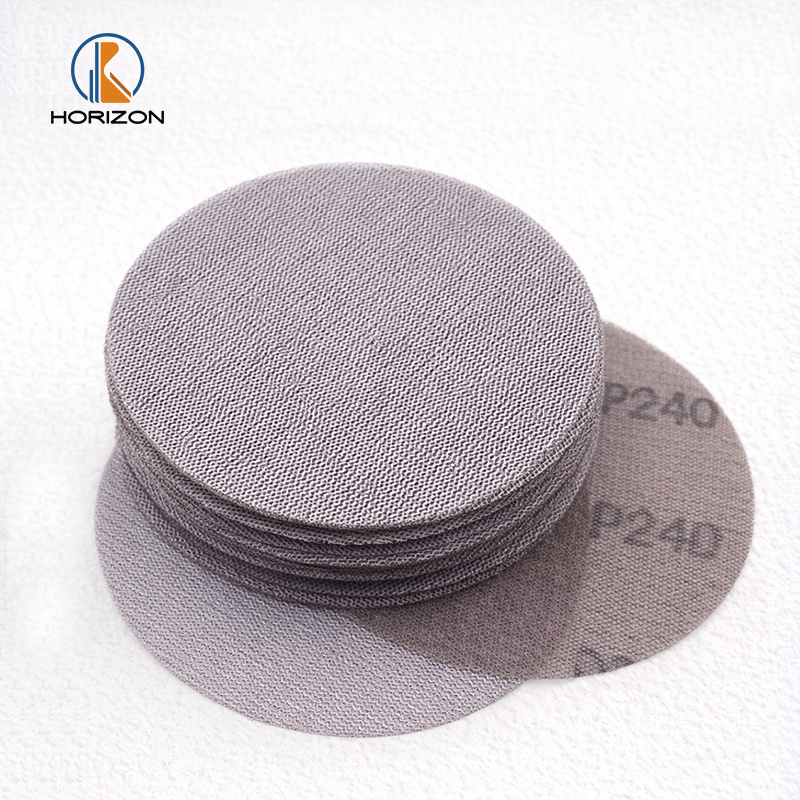

Technical Specifications

|

Item |

Specification |

| Abrasive |

Aluminum Oxide / Silicon Carbide |

|

Backing |

Premium Mesh / Net Backing |

| Grit Range |

P80 – P400 |

|

Diameter |

3″ / 4″ / 5″ / 6″ (75-150mm) |

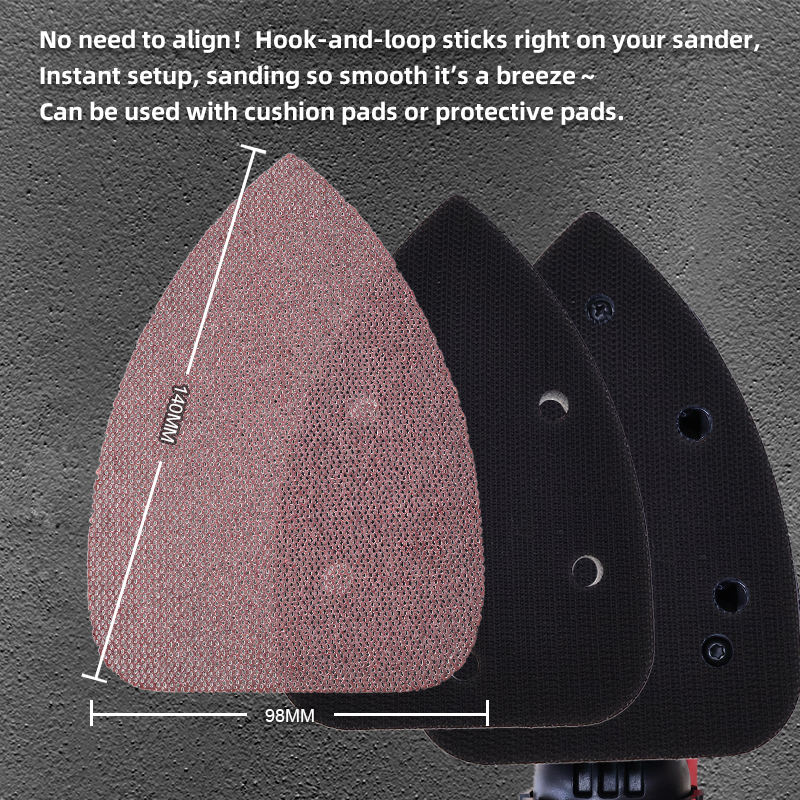

| Attachment |

Hook & Loop (Velcro) |

|

Dimensions |

Custom sizes available |

————————————————————————————————————————————————————————————————————————————————————

Processing Logic

Full-Surface Dust-Through Sanding Instead of Hole-Based Extraction

Conventional sanding discs rely on limited hole patterns, causing clogging between holes and premature abrasive failure.

Mesh sanding discs use a full-surface dust-through mechanism, keeping abrasives active and delivering more uniform, controlled sanding results.

————————————————————————————————————————————————————————————————————————————————————

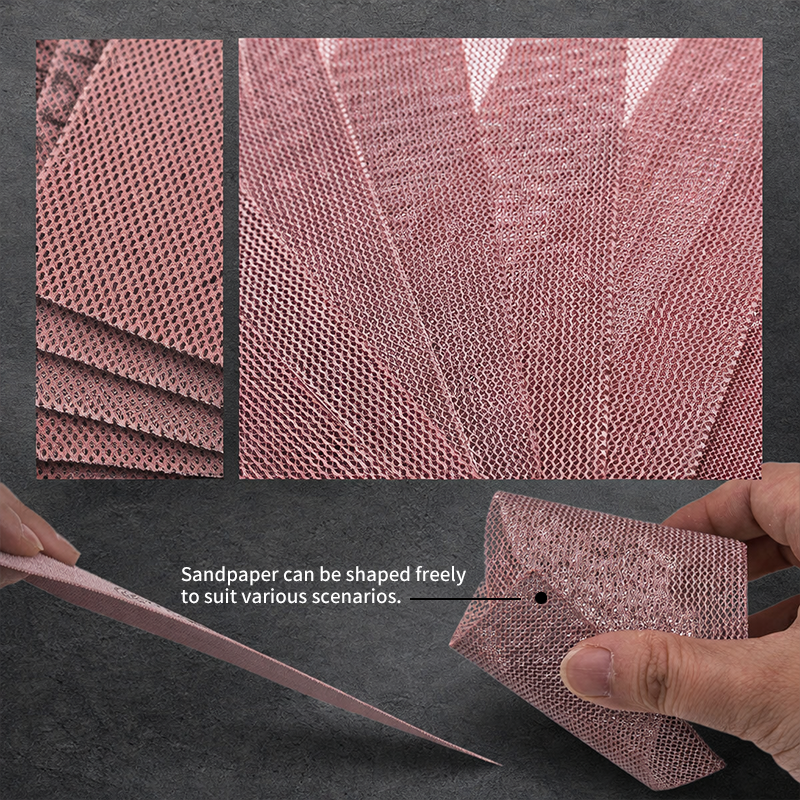

Backing Structure & Performance Limits

Designed for Clean Finishing, Not Heavy Stock Removal

- Mesh backing prioritizes dust evacuation and surface conformity

- Not intended for high-pressure or heavy stock removal

- Best suited for light to medium load finishing operations

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility & Operating Conditions

- Orbital sanders

- Random orbital sanders

- Electric or pneumatic tools with dust extraction ports

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison

|

Comparison |

Mesh Discs | Paper-backed Discs |

| Dust extraction | Full-surface |

Hole-based |

|

Anti-clogging |

★★★★★ | ★★ |

| Surface consistency | High |

Medium |

|

Service life |

Long | Medium |

| Work cleanliness | High |

Average |

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

- Automotive body repair and paint preparation

- Furniture and wood surface finishing

- Wall, putty, and coating sanding

————————————————————————————————————————————————————————————————————————————————————

Grit Range & Recommended Use

P80 – P120: Old coating removal and surface leveling

P150 – P240: Intermediate finishing

P320 – P400: Pre-paint surface preparation

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Disc-Level Dust Control Customization

OEM and ODM customization is available for disc diameter, mesh density, abrasive type, and packaging to match various machine brands and dust extraction systems.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Us

Effective Dust Control Starts from Abrasive Design

By engineering mesh backing structure, abrasive distribution, and coating stability, we deliver scalable, repeatable low-dust sanding disc solutions.

————————————————————————————————————————————————————————————————————————————————————

Usage & Storage Recommendations

- Best used with dust extraction systems

- Avoid excessive pressure

- Clean dust ports after use

- Store in a dry, shaded environment