Aluminum / Non-Ferrous Blades (TCT)

- Home

- Aluminum / Non-Ferrous Blades (TCT)

Categories

Aluminum / Non-Ferrous Blades (TCT)

Product Overview

Non-ferrous cutting relies on three pillars: TCG for burr control, chip evacuation + anti-loading (coating/wax), and stable plates for vibration/heat control

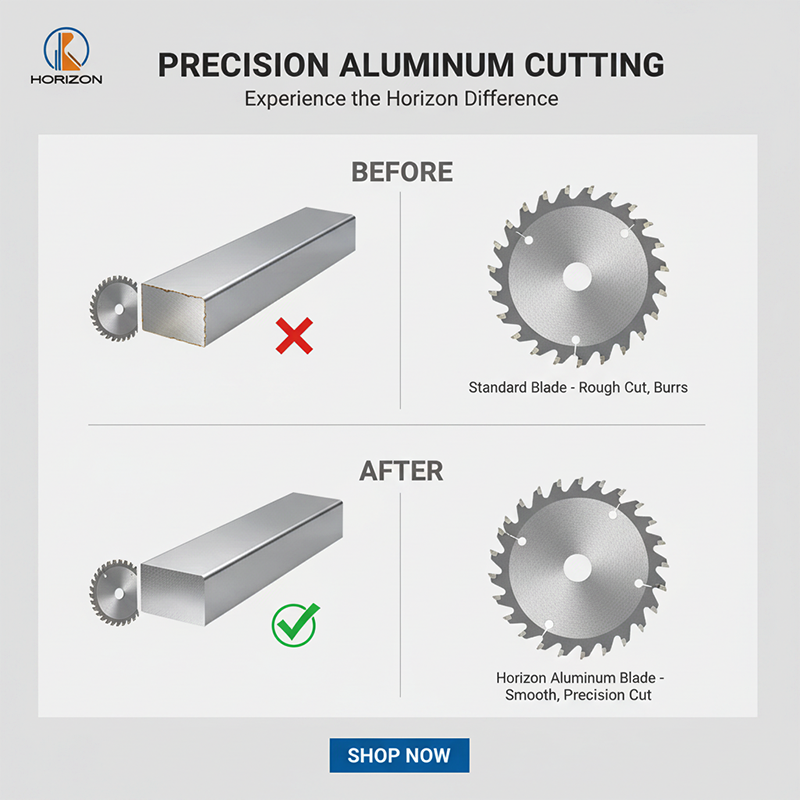

TCT blades engineered for aluminum & non-ferrous cutting—anti-loading, burr control and heat control for assembly-ready edges

Typical non-ferrous pain points include burrs, galling, chip loading, and high heat. Engineering controls include:

- TCG/optimized geometry: for burr reduction;

- Neutral/negative hook angles: for stability and reduced grabbing;

- Chip evacuation + anti-loading: via gullet design, surface treatment, wax/coating;

- Stable plates with slots/tensioning: to reduce vibration/noise and improve consistency.

Product Description

Product Positioning

Burr-control + anti-loading cutting tool for aluminum extrusion processing, fenestration, industrial profiles and non-ferrous cutting

Aluminum/non-ferrous TCT blades target stable cutting with anti-loading behavior, controlled burrs, and controlled heat, reducing secondary deburring and rework before assembly. Compared with wood, aluminum is prone to a chain reaction—chip adhesion → heat → galling → burr growth—so geometry and chip evacuation are engineered for the material.

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

For aluminum, “more teeth” isn’t the only answer—hook angle, chip evacuation, anti-loading and runout matter most

|

Specification |

Engineering Notes |

| Tooth Geometry |

Primarily TCG (For burr control); optimized geometries available based on workpiece requirements |

|

Hook Angle |

Neutral or negative hook angle: improves stability, reduces material pulling and “grabbing” |

| Tooth Count |

Configured by diameter and application: balances cut quality with chip evacuation |

|

Kerf |

Stability is priority; Thin kerf requires higher clamping precision and machine stability |

| Anti-loading |

Waxing / Coating / Surface treatments (Optional) + Optimized gullet design |

|

Runout |

Lower is better: Directly affects cut finish, burr formation, and tool life |

| Bore/Arbor |

20 / 25.4 / 30 mm etc. (Bushings/Reducers available) |

|

Materials |

Aluminum extrusions, Plates, copper, Brass, And other non-ferrous metals |

————————————————————————————————————————————————————————————————————————————————————

Key Features

Less burrs, less galling, less chip loading/heat—edges closer to “no secondary finishing”

- Burr control & edge integrity: via TCG behavior;

- Optional anti-loading: (wax/coating) reduces chip adhesion and galling;

- Controlled heat: through better evacuation and lower friction;

- Stable cutting feel: with neutral/negative hook and stable plates reduces grabbing.

————————————————————————————————————————————————————————————————————————————————————

Processing Logic

Aluminum cutting isn’t just separation—it’s turning friction into controlled chips; less loading means less burr and heat

The chain is tooth entry → chip formation → chip evacuation. If evacuation fails, chips rub, heat rises, aluminum loads, and galling/burrs grow. Aggressive hook angles can grab the work; runout/clamping issues amplify vibration and inconsistency. Selection must include machine stability and process window.

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility

Typical machines: miter/table/profile saw lines—clamping and support largely determine burrs and safety

- Miter/profile saws: prioritize secure clamping; stable hook angles and evacuation design;

- Table saws/jigs: prioritize low runout and straight tracking;

- Production lines: prioritize predictable life and sharpening cadence to reduce downtime.

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison

Key difference vs wood blades: wood cuts fibers; aluminum is sensitive to loading/galling, so anti-loading and hook-angle strategy are crucial

TCG vs Other Geometries

TCG is strong for burr control and stable edges; other grinds may be faster on certain profiles but are more process-sensitive.

Positive vs Negative Hook

Negative hook is more stable and less grabby with better burr control; positive hook can cut faster but increases grabbing/galling risk unless setups are very stable.

Anti-Loading Options

Wax/coating/surface treatment plus proper gullet design is an effective package to reduce loading and heat.

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

High-frequency processes in aluminum cutting—fenestration, industrial frames, heat sinks, furniture profiles and non-ferrous components

- Windows

- Curtain walls, Industrial profiles,Solar frames, Pre-machining cut-to-length, Display frames, Copper

- Brass cutting.

————————————————————————————————————————————————————————————————————————————————————

Range & Recommended Use

Select by burr target + loading tendency + machine stability—more reliable than tooth count alone

- Low burr / less galling: TCG + neutral/negative hook + anti-loading;

- Thick profiles/high load: stronger evacuation and stable plates; use coolant/lube if needed;

- Thin-wall profiles: clamping/support is critical to prevent vibration-driven burr growth.

- One-line rule: For aluminum, control loading first—TCG + evacuation + anti-loading + low runout beats “more teeth.”

————————————————————————————————————————————————————————————————————————————————————

Customization (OEM/ODM)

OEM/ODM tailored to your machines and burr standard—geometry, hook angle, anti-loading, assortments and private label packaging

OEM/ODM available:

Diameter, bore, tooth count, TCG parameters, hook angle (incl. negative), kerf/plate thickness, slots/damping features, wax/coating (optional), branding/private label packaging, barcodes and assortment kits.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Us

Engineering-led selection reduces claims—turn loading/burr/heat into manageable parameters, backed by stable supply

We translate your customer scenarios—profile thickness, machine platform, burr standard, coolant/lube constraints—into practical SKUs, backed by batch consistency and reliable lead time for repeat orders and reputation.

————————————————————————————————————————————————————————————————————————————————————

Usage & Storage Recommendations

Four essentials for non-ferrous cutting: clamping/support, process window, chip management, and coolant/lube strategy (optional)

- Clamping/support: secure the work to prevent vibration-driven burr growth and safety issues;

- Process window: if burrs/galling increase, adjust feed/RPM first, then move to more conservative hook/anti-loading;

- Chip management: keep chips evacuating, clean buildup to avoid friction heat;

- Coolant/lube (as needed): for heavy loads/loading-prone conditions, coolant or wax/coating helps reduce adhesion.