Ceramic Sanding Belts (Ceramic Alumina Belts)

- Home

- Ceramic Sanding Belts (Ceramic Alumina Belts)

Categories

Ceramic Sanding Belts (Ceramic Alumina Belts)

Premium Self-Sharpening Belts for Automated and High-Performance Grinding

Ceramic abrasives utilize a highly uniform microcrystalline structure that continuously and predictably generates new sharp cutting edges during grinding, enabling true continuous self-sharpening.

Compared to conventional abrasives, ceramic belts maintain cutting performance longer with a more stable wear curve.

Product Description

Ceramic Sanding Belts (Ceramic Alumina Belts)

Premium Self-Sharpening Belts for Automated and High-Performance Grinding

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

|

Item |

Specification |

| Abrasive |

Ceramic Alumina (Premium) |

|

Backing |

Heavy-duty Y-weight Polyester Cloth |

| Grit Range |

P24 – P150 |

|

Joint Type |

Butt Joint / Reinforced Joint |

| Bonding |

Full Resin Bond (Resin over Resin) |

|

Dimensions |

Custom sizes available upon request |

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Top-Tier Sanding Belts for Automated Production Lines

Ceramic sanding belts are premium industrial belts designed for high efficiency, stability, and automated continuous production, ideal for applications demanding maximum cutting performance and consistency.

————————————————————————————————————————————————————————————————————————————————————

Product Overview

Microcrystalline Abrasive and Continuous Sharp Cutting

Ceramic abrasives utilize a highly uniform microcrystalline structure that continuously and predictably generates new sharp cutting edges during grinding, enabling true continuous self-sharpening.

Compared to conventional abrasives, ceramic belts maintain cutting performance longer with a more stable wear curve.

————————————————————————————————————————————————————————————————————————————————————

Self-Sharpening Mechanism Comparison

Ceramic vs. Zirconia Engineering Differences

- Ceramic abrasives: Controlled microfracturing with consistent self-sharpening

- Zirconia abrasives: Block fracture requiring high pressure to self-sharpen

Ceramic belts maintain sharpness under medium to high loads, while zirconia belts rely more heavily on high-pressure conditions.

————————————————————————————————————————————————————————————————————————————————————

Automation & Production Line Compatibility

Designed for Consistency, Speed and Reduced Downtime

Ceramic belts are ideal for automated and unmanned production lines, where consistent cutting performance significantly reduces belt change frequency and improves overall equipment efficiency.

- Compatible with robotic sanding systems

- Suitable for multi-station continuous sanding lines

- Designed for high-throughput industrial production

————————————————————————————————————————————————————————————————————————————————————

Backing, Tension & High-Speed Operation

Structural Stability at Industrial Speeds

Y-weight cloth backing: Preferred for high tension and high speed

- Maintains dimensional stability at high belt speeds

- Splice strength is critical for automation

————————————————————————————————————————————————————————————————————————————————————

Process Flow & Productivity

Maximizing Throughput and Surface Quality

- High removal rates reduce process steps

- More consistent surface quality

- Lower total cost per part

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison with Zirconia Belts

|

Comparison |

Ceramic Belts | Zirconia Belts |

| Self-sharpening | Continuous microfracture |

Block fracture |

|

Load requirement |

Medium to high | High |

| Service life | Very long |

Long |

|

Automation suitability |

★★★★★ | ★★★★ |

| Cost | Higher |

Medium |

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

- Automated metal processing lines

- Stainless steel and high-alloy materials

- High-consistency industrial components

————————————————————————————————————————————————————————————————————————————————————

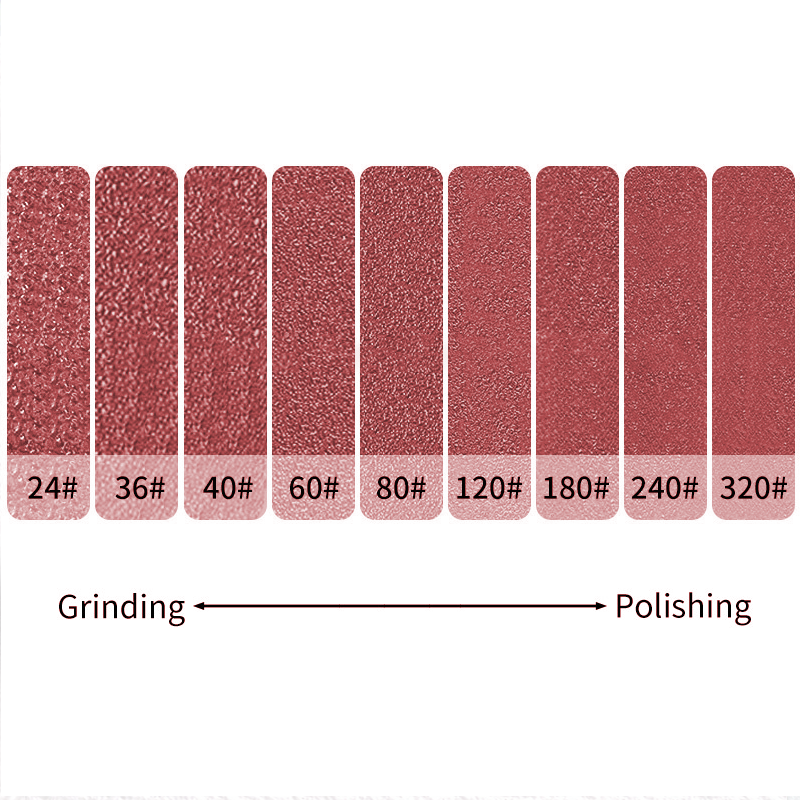

Grit Range & Recommended Use

- P24 – P36: Heavy grinding and weld removal

- P40 – P80: High-efficiency stock removal

- P100 – P150: Controlled shaping and surface finishing

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Premium Belt Engineering Solutions

We provide full OEM and ODM customization for ceramic belts, including reinforced splice design, backing engineering, and application validation for automated production lines.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our Ceramic Sanding Belts

Maximum Performance for Demanding Applications

With deep expertise in premium abrasives and belt engineering, we deliver ceramic sanding solutions with unmatched stability, efficiency, and predictability.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

- Run at recommended load during initial use

- Ensure correct splice orientation

- Store in temperature-controlled, dry conditions