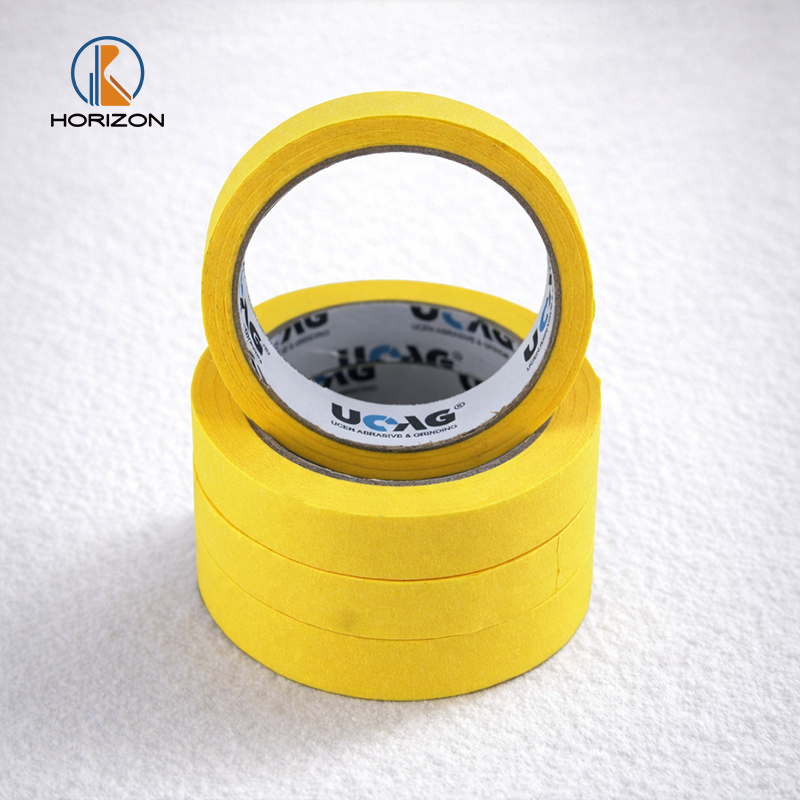

Masking Tape Series

- Home

- Masking Tape Series

Categories

Masking Tape Series

Product Overview

Paper Backing + Adhesive System + Temperature Grade = Performance

Clean Paint Lines, Reliable Adhesion and Residue-Control for Spray Painting and Surface Prep

Masking tapes combine crepe paper backing with an adhesive system. Backing conformity, coating uniformity, and temperature rating define application performance. Typical series include:

- General purpose: for routine masking and short cycles;

- High-temperature (refinish/bake): for booth/oven processes;

- Fine line: for sharper edges and smooth curves;

- Low-tack/sensitive surface: for cured paint, delicate substrates, and safer removal.

Product Description

Product Positioning

The Boundary-Control Component—Defines Line Sharpness, Rework Rate and Residue Risk

Masking tape is a core masking material for spray painting and surface prep—used for color separation, protecting non-spray areas, positioning, and station management. Its value is not just sticking, but controlling line sharpness, clean removal, residue risk, paint bleed-through, edge lifting, and stability under bake/high-temperature conditions.

In automotive refinish and industrial coating, wrong tape selection often causes sanding rework, re-masking, and re-spraying—costing far more than the tape itself.

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

Define by Adhesive Type, Temperature Rating, Thickness and Width

|

Item |

Specification |

| Backing |

Crepe paper backing |

|

Adhesive |

Rubber-based / Acrylic options |

| Temperature rating |

Standard / Mid-temp / High-temp |

|

Thickness |

Options (Affects conformity/Line) |

| Width |

1/4″–2″ (Extendable) |

|

Length |

20–50 m (Customizable) |

| Tack level |

Low/Medium/High tack |

|

Residue |

Low-residue Options |

| Color |

Natural/Tinted Options |

|

Packaging |

Standard/Private label/Kits |

————————————————————————————————————————————————————————————————————————————————————

Key Features

Sharp Lines, Conformity, Clean Removal and Heat Resistance

- Sharp paint lines: adhesive uniformity and backing conformity reduce bleed-through and fuzzy edges.

- Conformity on curves/edges: flexible backing reduces edge lifting.

- Heat/solvent resistance: baking processes require adhesion plus clean removability at elevated temperature.

- Low residue: clean removal reduces cleanup and rework.

- Process manageability: color/size systems support stage zoning (prep/spray/final).

————————————————————————————————————————————————————————————————————————————————————

Processing Logic

Boundary Sealing + Process Stability

Most masking failures come from:

- Poor conformity → edge lift → paint bleed/overspray

- Wrong adhesive system → poor tack at low temp or adhesive flow at bake temp → residue/edge distortion

- Wrong removal timing → paint lifting → rework

Correct tape seals the boundary with the right adhesive and temperature rating while maintaining stable adhesion and clean removability through the job cycle.

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility

Spray Booths/Ovens, Hand Masking and Industrial Lines

- Use environments: hand masking, spray booths/ovens, production masking/color separation

- Must match: temperature rating (bake or not), substrate type (bare metal/primer/topcoat/plastics), masking duration (short vs extended)

- Workflow linkage: works with masking film/pre-taped film, tack cloth, and cleaners to achieve reliable masking.

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison

|

Dimension |

Rubber-based | Acrylic |

| Initial tack | ★★★★★ |

★★★ |

|

Heat/Aging Resistance |

Medium | ★★★★★ |

| Residue Risk | Medium (Sensitive to long-term/high-heat) |

Low (More stable) |

|

Typical Use |

General masking, fast-paced application |

High-temp baking, long-term masking |

|

Dimension |

General Purpose | High-Temp |

| Process | Ambient temperature spraying |

Bake booth / Drying cycle |

|

Edge stability |

Mid – High | ★★★★★ |

| Clean removal | Mid – High |

★★★★★ |

|

Dimension |

Standard | Fine Line |

| Line Sharpness | ★★★★ |

★★★★★ |

|

Curve Ability |

Medium | ★★★★★ |

| Cost | Low – Medium |

Mid – High |

|

Typical Use |

Large area masking |

Color separation / Multi-tone design |

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

Automotive Refinish, Industrial Coating, Furniture, Metal & Plastic Parts

- Automotive refinish: color separation, edge protection, bake masking

- Industrial coating: line masking, hole protection, zoning/color separation

- Furniture: large-area masking, corners, styling lines

- Metal/plastic parts: pre-spray protection and post-spray clean removal

————————————————————————————————————————————————————————————————————————————————————

Range & Recommended Use

Quick Selection by Temperature, Surface, Duration, Line Requirement

- Bake/oven involved: choose high-temp tape (better stability and clean removal)

- Cured paint/sensitive surfaces: low-tack/low-residue series; spot test first

- Sharp color lines: use fine line at the edge, over-mask with general/high-temp tape

- Large-area masking: general tape + masking film/pre-taped film for best efficiency

One-line rule: Temperature first, then surface sensitivity, then decide fine line for edge quality.

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Adhesive Systems, Temp Grades, Color Coding and Private Label Tape Programs

OEM/ODM supported:

Adhesive system (rubber/acrylic), temperature grades, thickness and backing conformity, width/length assortments, color coding by process stage, low-residue and low-tack customization, printing/private label packaging, and masking kits bundled with films and accessories.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Us

Stable Adhesion Curve and Clean Removal Reduce Rework in Coating Lines

Masking tape success is not maximum tack but a stable adhesion curve:

Sticks well, survives the process, and removes cleanly. We provide series-based selections and OEM/ODM private label programs aligned to temperature, masking duration, and line sharpness—reducing bleed, lifting, and residue rework.

————————————————————————————————————————————————————————————————————————————————————

Usage & Storage Recommendations

Clean Surface, Firm Press, Remove at the Right Time

- Ensure surfaces are clean and dry before masking; oil/dust causes lifting and bleed-through

- Press firmly along the edge; apply in segments on curves/corners to reduce tension

- Remove within the proper paint window (film set but not fully hardened) to reduce paint lifting (process-dependent)

- Store dry and shaded; avoid heat/compression; reseal after opening; manage lots FIFO