Metal Backing Flap Discs

- Home

- Metal Backing Flap Discs

Categories

Metal Backing Flap Discs

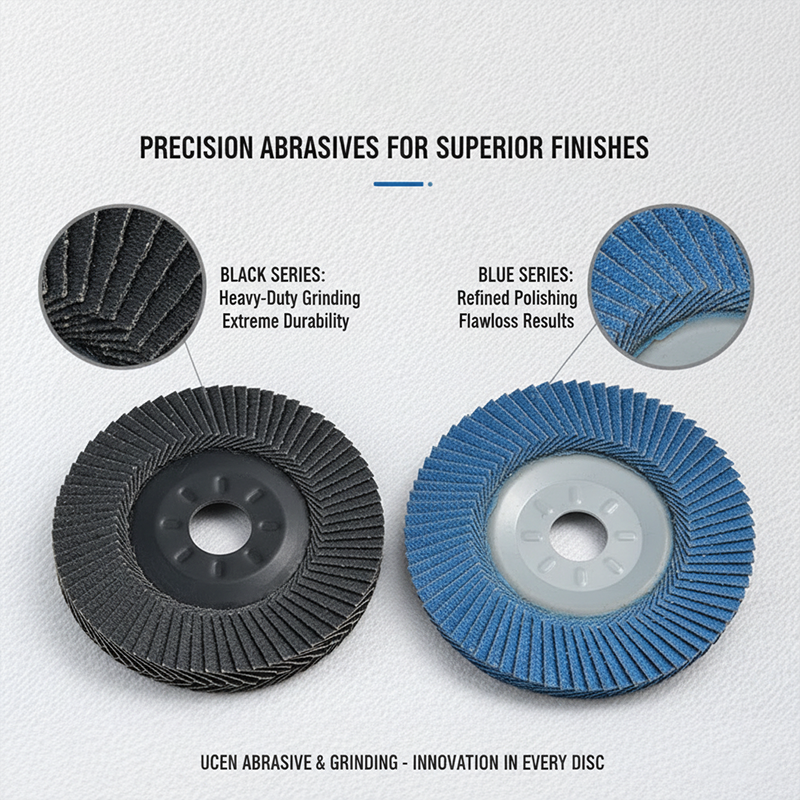

Heavy-Duty Flap Discs for Aggressive Grinding, Edge Work & Weld Removal

Metal backing flap discs consist of layered coated-abrasive flaps bonded to a metal backing plate (often steel/alloy). The metal backing brings:

- Higher rigidity for stable angles, especially on edges;

- Stronger impact tolerance for higher pressure grinding;

- More direct heat conduction (still requires correct technique).

Product Description

Product Positioning

A More Rigid, More Aggressive Flap Disc for Heavy Grinding & Edge Stability

Metal backing flap discs are positioned for heavy stock removal and edge/corner work on angle grinders. When you need higher rigidity, more stable grinding angles, and stronger impact resistance (e.g., fast weld removal, chamfering, edge dressing), metal backing delivers a firmer grinding feel and stronger structural support than fiberglass backing.

—————————————————————————————————————————————————————————————————————————————————————————-

Technical Specifications

Configurable by Market Standards and Working Conditions

|

Item |

Specification |

| Product Type |

Metal backing flap discs |

|

Abrasive |

AO / Zirconia / Ceramic options |

|

Shape |

Type 27 (Flat) / Type 29 (Conical) |

|

Outer Diameter |

4″ / 4.5″ / 5″ / 7″ |

|

Mounting Type |

Arbor hole / Threaded hub (5/8″-11, M14) |

| Grit Range |

P36 – P120 (extendable) |

| Backing Plate |

Metal backing (High-strength steel/alloy) |

| Max RPM |

Marked per size & industrial standards |

—————————————————————————————————————————————————————————————————————————————————————————-

Processing Logic

Aggressive Removal Driven by Stable Angles and Sustained Pressure

Metal backing discs favor a working mode of steady angle + sustained pressure:

- Rigid backing keeps a stable grinding angle;

- Higher efficiency on weld reinforcement and edges/chamfers;

- For broad surface blending, control pressure/angle to avoid gouging.

—————————————————————————————————————————————————————————————————————————————————————————-

Backing Structure & Performance Limits

More Rigid Advantages, More Rigid Boundaries

Strengths:

rigidity, impact tolerance, and superior edge stability.

Limits:

metal backing is not “forgiving”—excess pressure or dwelling can still overheat/discolor or gouge the surface; requires more controlled technique than fiberglass backing.

—————————————————————————————————————————————————————————————————————————————————————————-

Machine Compatibility & Operating Conditions

Angle Grinders: Speed Rating, Mounting & Guarding

- Machines: angle grinders (electric/pneumatic).

- Typical mounting: arbor-hole (with flange) / threaded hub (e.g., 5/8″-11, M14—market-based).

- Must match: grinder RPM ≤ disc max RPM; always use guards and PPE.

—————————————————————————————————————————————————————————————————————————————————————————-

Engineering Comparison

Metal vs Fiberglass: Rigidity vs Blending Forgiveness

|

Comparison |

Metal Backing | Fiberglass Backing |

| Rigidity & angle stability | ★★★★★ |

★★★★ |

|

Edge/chamfer efficiency |

★★★★★ | ★★★★ |

| Impact tolerance | ★★★★★ |

★★★★ |

|

Blending friendliness |

★★★ | ★★★★★ |

| Comfort/vibration feel | Medium |

More forgiving |

|

Typical choice |

Heavy grinding & edges |

Blending & general use |

—————————————————————————————————————————————————————————————————————————————————————————-

Typical Applications & Industries

Efficiency Tool for Heavy Metal Grinding & Edge Dressing

- Fast weld reinforcement removal and weld dressing

- Deburring and chamfering for structural steel and sheet metal

- Edge dressing and corner rounding (with proper grit and angle)

- Metal surface cleaning: light scale/old coating prep (abrasive-dependent)

—————————————————————————————————————————————————————————————————————————————————————————-

Grit Range & Recommended Use

From Heavy Grinding to Blending: Typically P36–P120

Typical recommendation

- P36–P40: heavy grinding and fast weld removal

- P60: general-purpose removal + blending (most popular)

- P80–P120: scratch refinement, blending, and edge finishing

—————————————————————————————————————————————————————————————————————————————————————————-

OEM & ODM Capability

Deep Customization from Specs to Structure

OEM/ODM supported: diameter and arbor/thread systems (market-based), Type 27/29, abrasive systems (AO/ZA/Ceramic), flap count & layup angle, backing thickness/profile, private label & packaging, and carton programs.

—————————————————————————————————————————————————————————————————————————————————————————-

Why Choose Us

Heavy-Duty Consistency Comes from Backing + Layup + Bonding

For metal backing flap discs, stability is not just about abrasive grain—backing rigidity, flap layup angle, and bonding system determine cutting force, heat behavior, and life consistency. We control structure and process for batch reliability, delivering predictable productivity and feel in continuous operation.

Usage & Storage Recommendations

Safety First: RPM, Guarding, Angle & Pressure

- Never overspeed: grinder RPM must be ≤ disc max RPM; use guards and PPE.

- Maintain a steady working angle; avoid dwelling to reduce overheating and gouging.

- Store dry and shaded; avoid moisture and heavy compression; reseal after opening to prevent dust/humidity.