Nonwoven Interleaved Flap Wheels

- Home

- Nonwoven Interleaved Flap Wheels

Categories

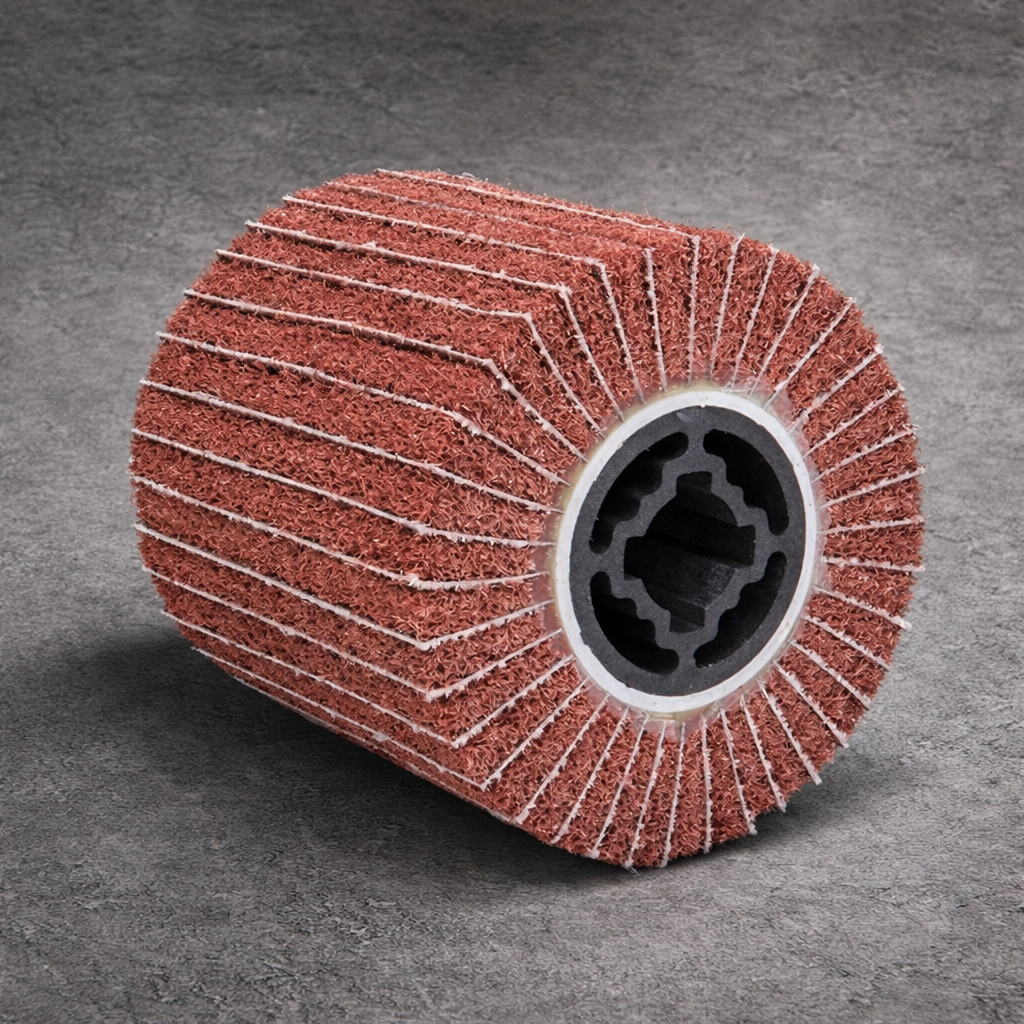

Nonwoven Interleaved Flap Wheels

Product Overview

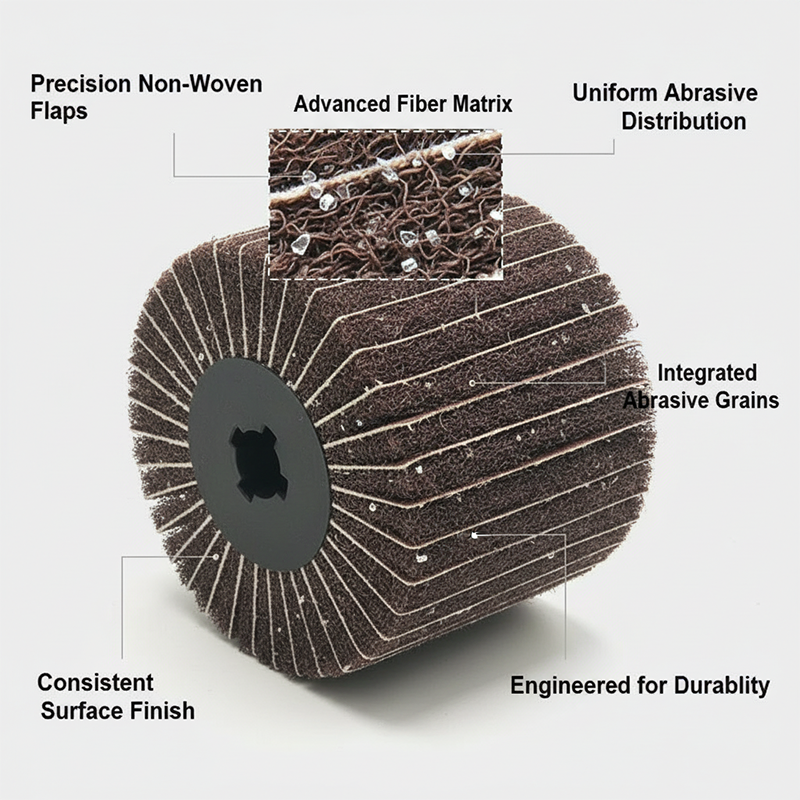

Alternating Nonwoven Flaps for Controlled Abrasion and Uniform Texture

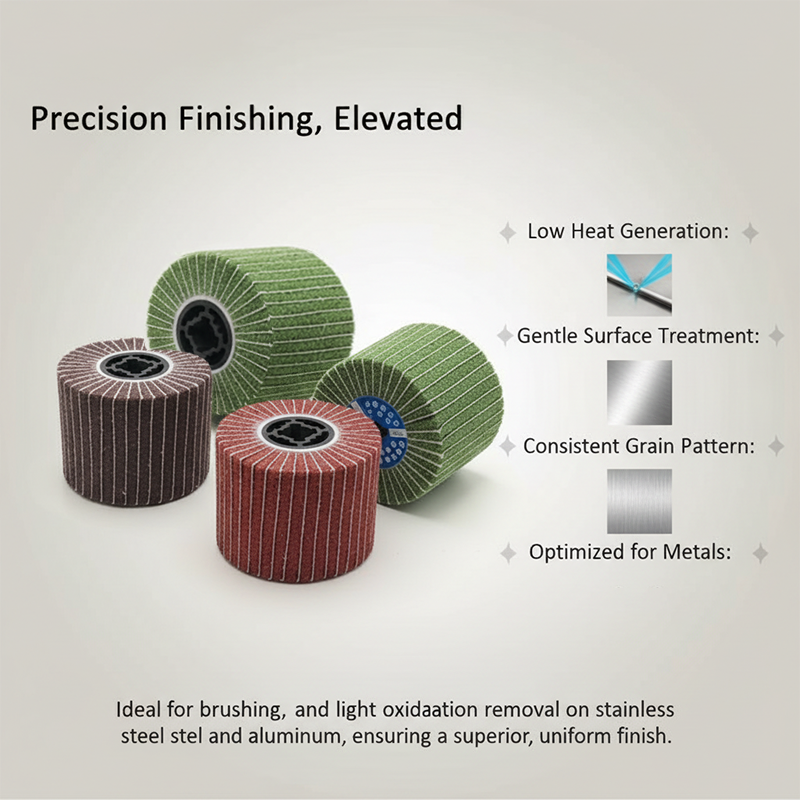

Low-Heat Surface Conditioning Wheels for Brushing, Blending & Cosmetic Finishing

These wheels use interleaved nonwoven flaps (with abrasive-impregnated/coated grades). The open nonwoven structure provides compliant contact, resulting in:

- Lower heat concentration and reduced discoloration risk;

- Gentler surface interaction with shallower, more uniform scratches;

- Better suitability for large cosmetic surfaces requiring brushing and blending.

The interleaved build maintains flexibility while ensuring stable continuous contact.

Product Description

Product Positioning

Surface Conditioning Wheels for Cosmetic Texture with Low Heat

Interleaved nonwoven flap wheels are positioned as surface conditioning and texture-forming tools, prioritizing low heat, low gouging risk, and consistent scratch patterns for cosmetic finishing on stainless steel, aluminum, and decorative parts.

They are not designed for maximum stock removal, but for repeatable surface aesthetics—essential consumables for finishing stations and appearance-critical workflows.

—————————————————————————————————————————————————————————————————————————————————————————-

Technical Specifications

Configurable by Grade, Density and Wheel Geometry

|

Item |

Specification |

| Product Type |

Interleaved nonwoven flap wheels |

|

Material |

Nonwoven (Abrasive-impregnated/Coated) |

| Construction |

Interleaved flap construction |

|

Outer Diameter |

1.25″–12″ (30–300 mm)(Extendable) |

| Width |

3/8″–8″ (10–200 mm)(Extendable) |

|

Arbor Hole |

1/4″–2″ (Customizable) |

| Grade |

Coarse/Medium/Fine (C / M / F)(Extendable) |

|

Max RPM |

Marked per size & Standard |

—————————————————————————————————————————————————————————————————————————————————————————-

Processing Logic

Buffered Conditioning Turns Scratches into Controlled Texture

- The logic is surface conditioning:

- Nonwoven fibers buffer peak cutting, reducing gouging risk;

- Uniform micro-abrasion creates brushing, light deburring, and blending;

- Especially valuable for stainless cosmetic parts where deep scratches and heat discoloration cause costly rework.

—————————————————————————————————————————————————————————————————————————————————————————-

Backing Structure & Performance Limits

Excellent for Appearance, Not for Heavy Stock Removal

- Strengths: low heat, uniform texture, surface-friendly, high cosmetic consistency

- Limits: limited stock removal; weld reinforcement and heavy burrs should be removed first with flap discs or belts

- Pressure-sensitive: excessive pressure compresses the nonwoven, harming texture uniformity and increasing heat

—————————————————————————————————————————————————————————————————————————————————————————-

Machine Compatibility & Operating Conditions

Finishing Machines and Profile Stations with Stable Speed Control

- Machines: finishing machines/polishers/sanders with bore mounting; some setups may be used with angle grinders (depending on design and safety spec)

- Recommended: medium to low pressure, stable surface speed, continuous movement/feed

- Must match: wheel size, bore/arbor, RPM rating (never overspeed), and desired brushing direction (feed direction controls texture direction)

—————————————————————————————————————————————————————————————————————————————————————————-

Engineering Comparison

|

Comparison |

Interleaved Nonwoven Wheels | Standard Flap Discs | Nonwoven Conditioning Discs |

| Stock removal | Low–Medium | High |

Low |

|

Texture consistency |

Excellent | Medium–Good | Excellent |

| Heat/discoloration risk | Low | Medium |

Low |

|

Gouging risk |

Low | Medium | Low |

| Typical use | brushing/blending | removal/welds |

conditioning/cleaning |

—————————————————————————————————————————————————————————————————————————————————————————-

Typical Applications & Industries

Cosmetic Finishing for Stainless, Aluminum and Decorative Components

- Brushing, blending, and light scratch removal for stainless cosmetic parts

- Texture unification and light oxide removal for aluminum

- Decorative hardware, handrails, profiles, enclosures, architectural components

- Process transition stage—from removal to cosmetic texture finishing

—————————————————————————————————————————————————————————————————————————————————————————-

Range & Recommended Use

Grade Strategy for Brushing and Blending

Typical grade logic

Nonwoven wheels are commonly specified by grades (Coarse/Medium/Fine), with market variations:

- Coarse: light oxide removal, fast brushing formation, initial blending

- Medium: general texture unification and blending (most common)

- Fine / Very Fine: cosmetic refinement, reduced visible scratching, enhanced surface aesthetics

—————————————————————————————————————————————————————————————————————————————————————————-

OEM & ODM Capability

Texture and Appearance Customization

OEM/ODM supported: nonwoven density/grade, abrasive impregnation system, OD/width/bore, interleaving ratio and hardness, core material and balance grade, private labeling/packaging and kit programs—engineered for target texture (direction, coarseness, gloss) and material type.

—————————————————————————————————————————————————————————————————————————————————————————-

Why Choose Us

Cosmetic Consistency Comes from Density, Grade and Balance Control

Cosmetic parts demand batch consistency: nonwoven density, grade stability, and wheel balance determine texture uniformity, heat behavior, and stripe variation risk. We control materials and structure for repeatable appearance finishing.

—————————————————————————————————————————————————————————————————————————————————————————-

Usage & Storage Recommendations

Keep Texture Uniform—Avoid Over-Compression

Use medium to low pressure with stable speed and continuous movement to avoid compressing the nonwoven and creating uneven texture

For stainless cosmetic work: remove weld/burrs first with flap discs/belts, then use nonwoven wheels for blending/brushing

Store dry and shaded; moisture can affect nonwoven resilience and grade stability; reseal after opening