Sanding Sponge Sheets

- Home

- Sanding Sponge Sheets

Categories

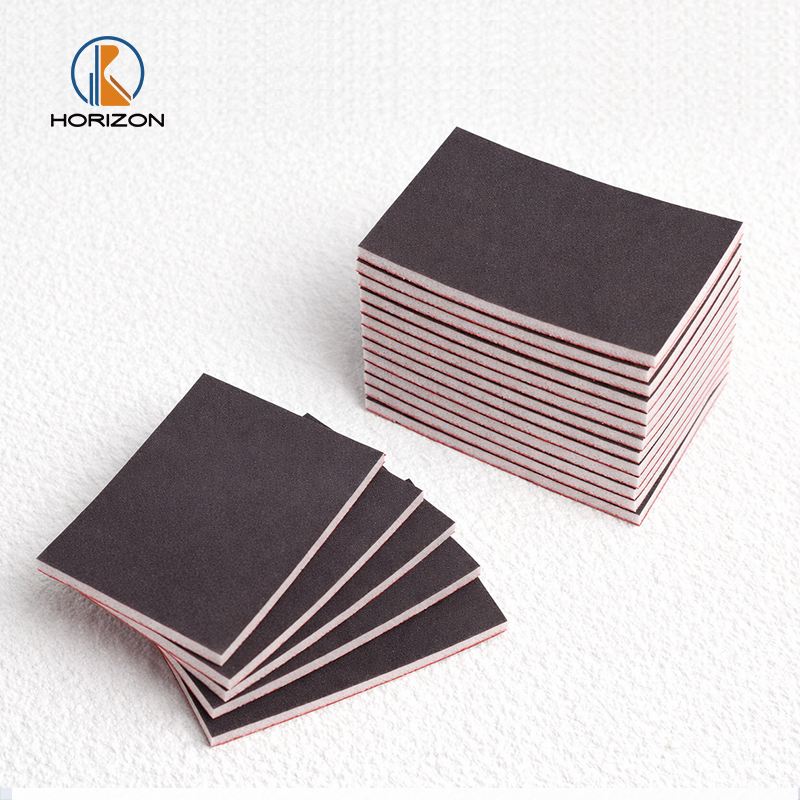

Sanding Sponge Sheets

Product Overview

Foam-Backed Abrasive Sheets with Wide Coverage and High Conformity

Cut-to-Size Flexible Sanding Sheets for Hand Finishing, Contours and Wet/Dry Prep

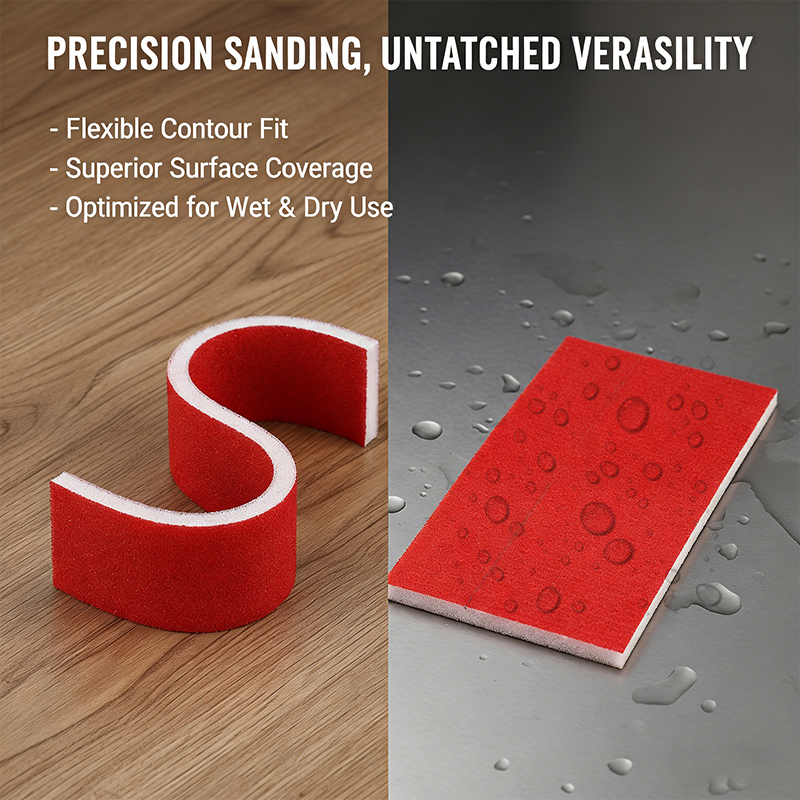

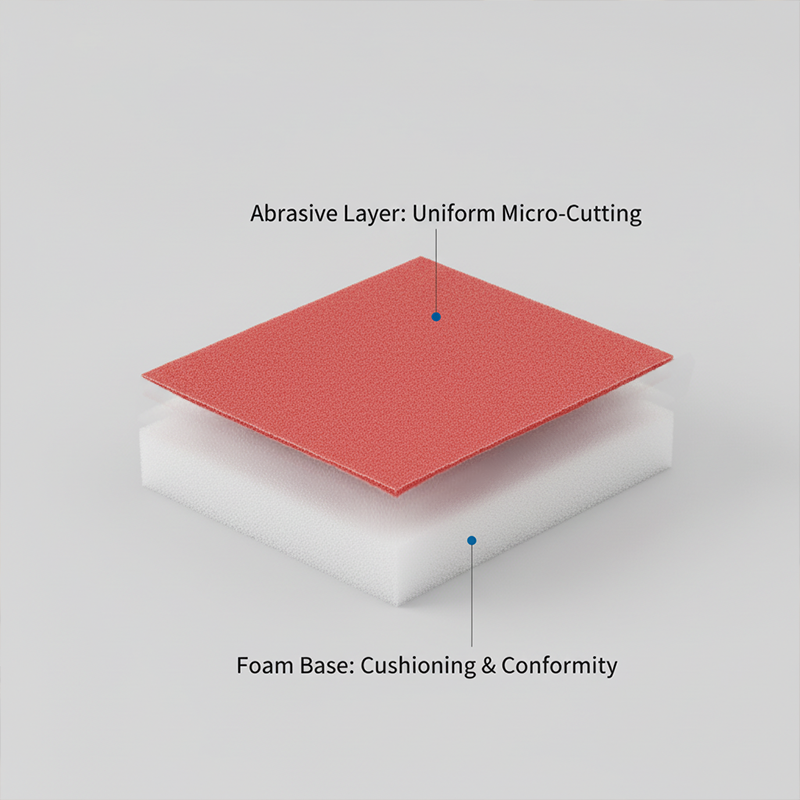

Sanding sponge sheets combine a foam backing with an abrasive working layer in a sheet format, easily cut to fit part shapes. The foam provides cushioning and conformity while the abrasive performs uniform micro-cutting, enabling:

- More even pressure distribution and scratch consistency over large areas;

- Safer edge/chamfer behavior with reduced burn-through/gouging risk;

- Dry and wet sanding options depending on construction.

Product Description

Product Positioning

Flexible Cut-to-Size Sheets for Large-Area Hand Finishing

Sanding sponge sheets are positioned as large-area, cut-to-size, conformable hand sanding media. When users need uniform finishing on larger surfaces while maintaining smooth transitions over curves and edges, sponge sheets are more efficient than blocks and more forgiving than paper sandpaper.

They are widely used as workhorse consumables for pre-paint prep, wood finishing, composites, and cosmetic touch-ups.

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

Configurable by Size, Foam Density and Wet/Dry Construction

|

Item |

Specification |

| Product Type |

Premium Sanding Sponge Sheets / Flexible Abrasive Foams |

|

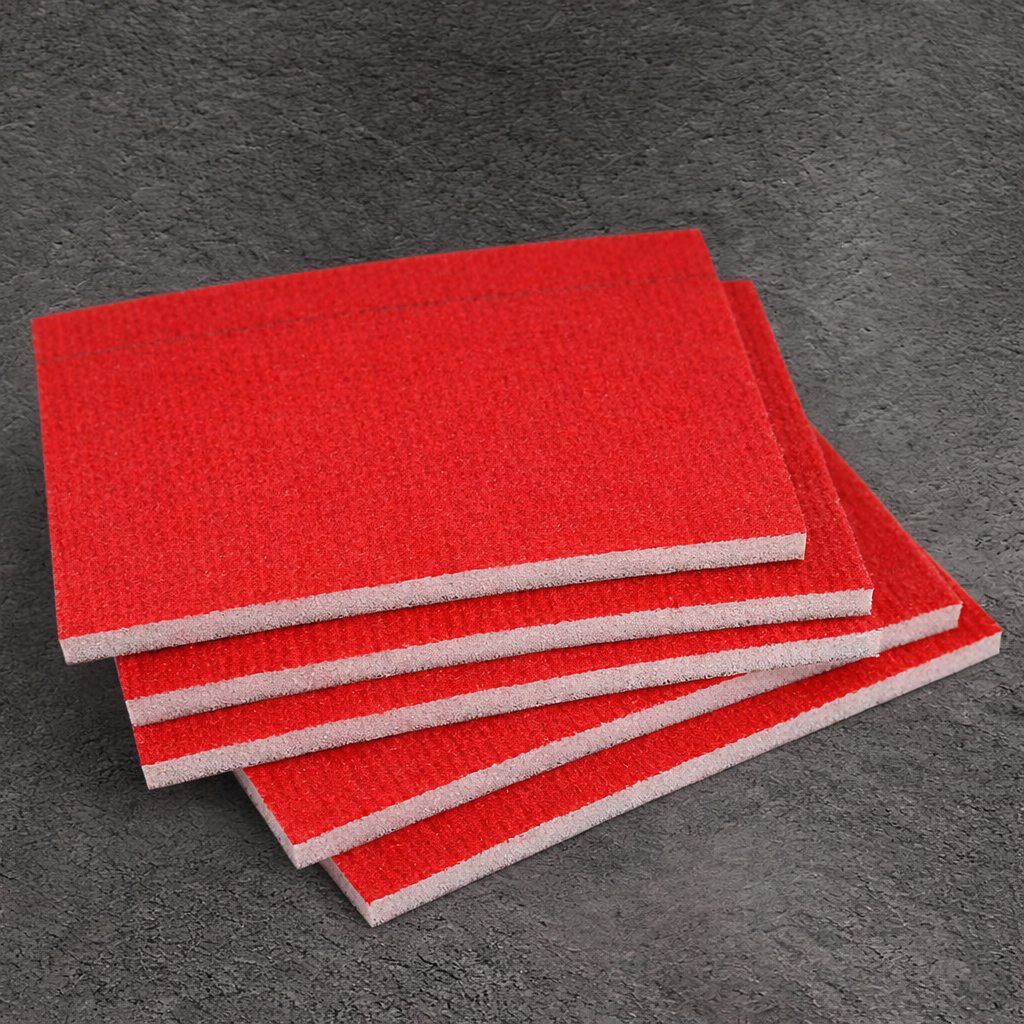

Construction |

High-resilience foam backing + Integrated abrasive layer |

| Sheet Dimensions |

Standard sizes & bespoke custom dimensions available |

|

Thickness Range |

0.04″ – 0.4″ (1.0 mm – 10.0 mm) – Fully customizable |

| Foam Density |

Soft / Medium / Hard (Density tailored to application) |

|

Grit Range |

P120 – P800 (Extended grit ranges available upon request) |

| Application Mode |

Dual-purpose: Optimized for both Wet & Dry sanding |

|

Packaging |

Custom OEM retail packaging and private labeling options |

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison

|

Comparison |

Sponge Sheets | Sponge Blocks | Paper Sandpaper Sheets |

| Large-area efficiency | ★★★★★ | ★★★ |

★★★★ |

|

Cut-to-fit |

★★★★★ | ★★ | ★★★★★ |

| Conformity | ★★★★★ | ★★★★★ |

★★★ |

|

Edge friendliness |

★★★★★ | ★★★★★ | ★★★ |

| Removal rate | Medium | Low–Medium |

Medium–High |

————————————————————————————————————————————————————————————————————————————————————

Processing Logic

Cut-to-Fit + Soft Contact Improves Efficiency and Consistency

Two key advantages drive performance:

- Cut-to-fit adaptability: trim to match contours (curves, grooves, around holes) for better conformity and less waste;

- Soft buffered contact: foam distributes pressure, reducing deep scratches and edge gouging, making hand finishing more repeatable.

In coatings, primers, and wood finishing, sponge sheets often reduce rework significantly.

————————————————————————————————————————————————————————————————————————————————————

Backing Structure & Performance Limits

Best for Refinement, Not Heavy Leveling

- Strengths: efficient for large-area hand work, conforms well, strong scratch uniformity

- Limits: lower removal rate than paper sandpaper (same grit) or machine belts; heavy defects should be removed first with more aggressive tools

- Foam wears: over-pressure or dwelling increases heat and foam fatigue, harming texture consistency

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility & Operating Conditions

Hand Sanding, Hand Pads and Controlled Fixture Use

- Primary use: hand sanding (can be used with hand pads for uniform pressure)

- Recommended: medium to low pressure, sand along intended direction; control cross-sanding to avoid random scratches

- Wet sanding: helps dust control and reduces loading on primers/coatings (process-dependent)

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

Large-Area Hand Finishing in Coatings, Wood and Composites

- Automotive refinishing: primer/clearcoat prep, localized touch-ups

- Wood/furniture: sealer/primer finishing and grain-direction refinement

- Industrial coating: hand correction of coating defects and pre-paint prep

- Composites: surface refinement and edge transitions (pressure/heat control required)

————————————————————————————————————————————————————————————————————————————————————

Range & Recommended Use

Grit Strategy for Hand Refinement and Pre-Paint Prep

- P120–P180: general refinement, light orange peel correction, blending

- P240–P320: primer finishing and pre-paint prep (most common)

- P400–P800: high-end cosmetic prep and final finishing (coating-system dependent)

————————————————————————————————————————————————————————————————————————————————————

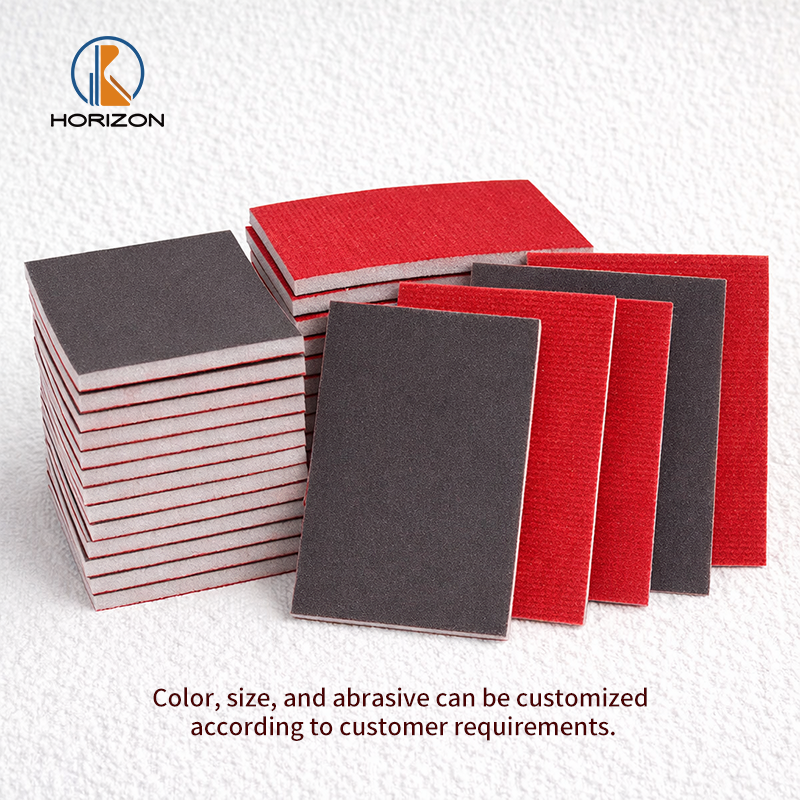

OEM & ODM Capability

Cut-to-Fit Sheet Engineering for Different Processes

OEM/ODM supported:

Sheet sizes and cutting formats, foam thickness/hardness, abrasive system and grit combinations, dry/wet grades, anti-slip/laminated back constructions, colors and packaging, and process-based kits—engineered for target feel, life, and scratch outcomes.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Us

Uniform Hand Finishing Requires Foam Stability and Abrasive Consistency

Uniform hand finishing depends on foam stability and abrasive consistency:

Foam controls pressure distribution and conformity; coating and bonding control scratch consistency and wear curve. We engineer for batch stability to make large-area hand finishing repeatable.

————————————————————————————————————————————————————————————————————————————————————

Usage & Storage Recommendations

Keep Sheets Flat, Dry and Clean

- Use medium to low pressure and sand along intended direction; control cross-sanding to avoid random scratches

- For wet sanding, rinse and air-dry after use to prevent mold and bond degradation

- Avoid heat, sunlight, and solvent exposure to prevent foam aging and structure failure

- Store flat, dry, and shaded; avoid folding/compression; reseal after opening to keep clean and dry