Velcro Sanding Discs

- Home

- Velcro Sanding Discs

Categories

Velcro Sanding Discs

Velcro Sanding Discs (Hook & Loop Sanding Discs)

Secure Attachment, Stable Cutting and Consistent Finish

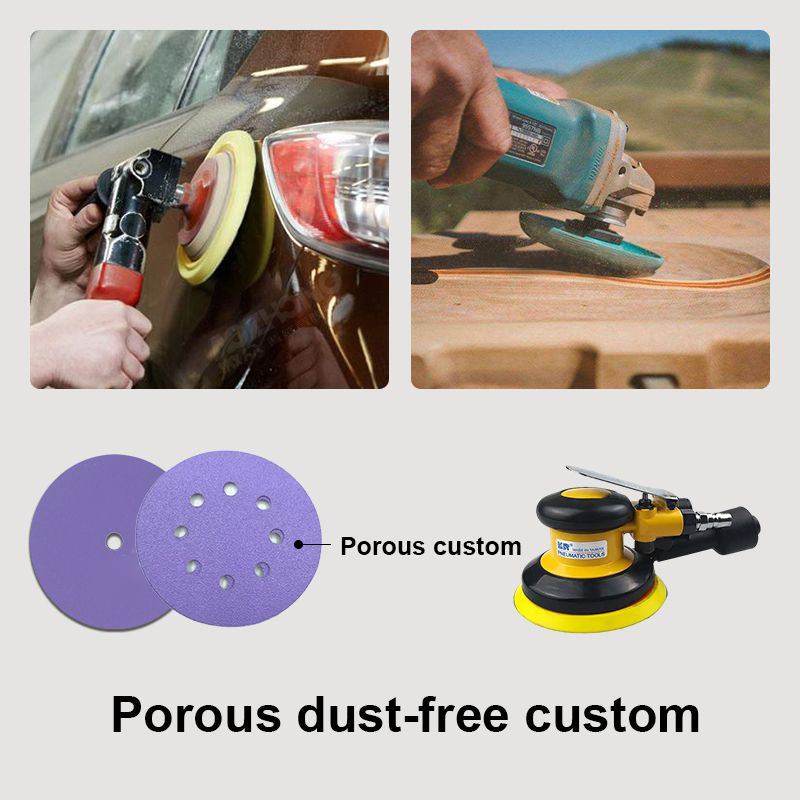

Velcro sanding discs are ready-to-use abrasive products designed for quick change on orbital, random orbital, and finishing sanders. They are widely used in woodworking, furniture manufacturing, automotive refinishing, and industrial surface preparation.

Product Description

Velcro Sanding Discs (Hook & Loop Sanding Discs)

Efficient, Fast-Change Sanding Discs for Orbital and Random Orbital Sanders

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

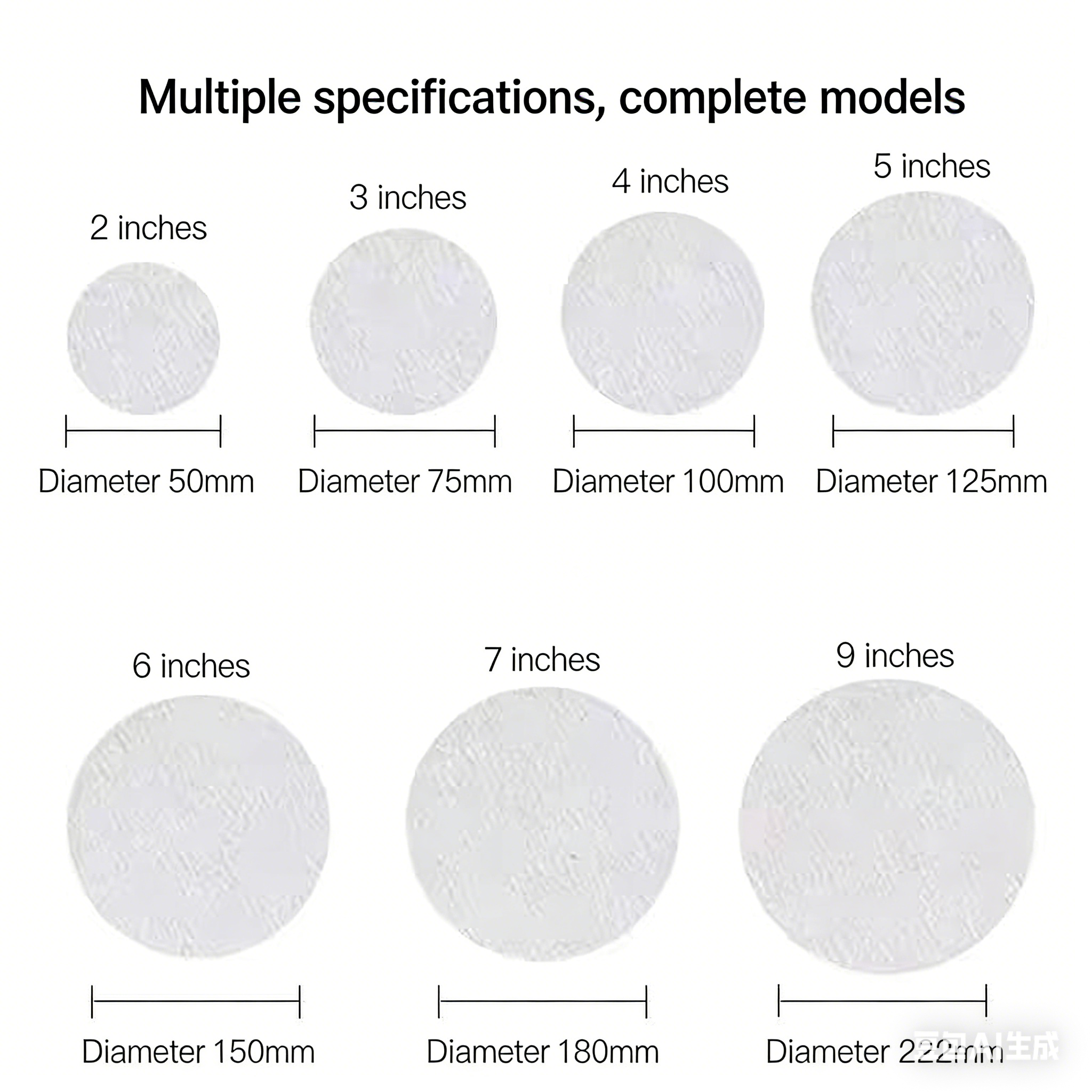

Disc Size, Grit Range and Custom Options

| Item | Specification |

| Diameter | 3″ / 4″ / 5″ / 6″ / 7″ (75-180mm) |

| Abrasive Type | Aluminum Oxide / Ceramic / Silicon Carbide |

| Grit Range | P40 – P3000 |

| Backing | Paper / Film backing |

| Hole Pattern | No hole / Multi-hole (e.g., 5/6/8/15/Universal) |

| Bonding | Resin over Resin (Full resin bond) |

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Ready-to-Use Finished Abrasive Discs for Machine Sanding

Velcro sanding discs are ready-to-use abrasive products designed for quick change on orbital, random orbital, and finishing sanders. They are widely used in woodworking, furniture manufacturing, automotive refinishing, and industrial surface preparation.

————————————————————————————————————————————————————————————————————————————————————

Product Overview

Secure Attachment, Stable Cutting and Consistent Finish

Our Velcro sanding discs feature high-strength hook & loop backing combined with stable abrasive coating technology, ensuring secure attachment without slippage during high-speed operation.

They are designed for continuous industrial use, balancing cutting efficiency, heat dissipation, and service life.

————————————————————————————————————————————————————————————————————————————————————

Abrasive Grain Selection by Application

Matching Cutting Performance to Workpiece Materials

Different abrasive grains are available to match specific materials and sanding requirements.

Aluminum Oxide

Suitable for wood, metals, and general surface finishing, offering stable cutting and balanced lifespan.

Ceramic Abrasive

Designed for heavy stock removal and high-efficiency industrial sanding, featuring excellent self-sharpening performance.

Silicon Carbide

Ideal for fine sanding, stainless steel, and coating preparation where surface quality is critical.

————————————————————————————————————————————————————————————————————————————————————

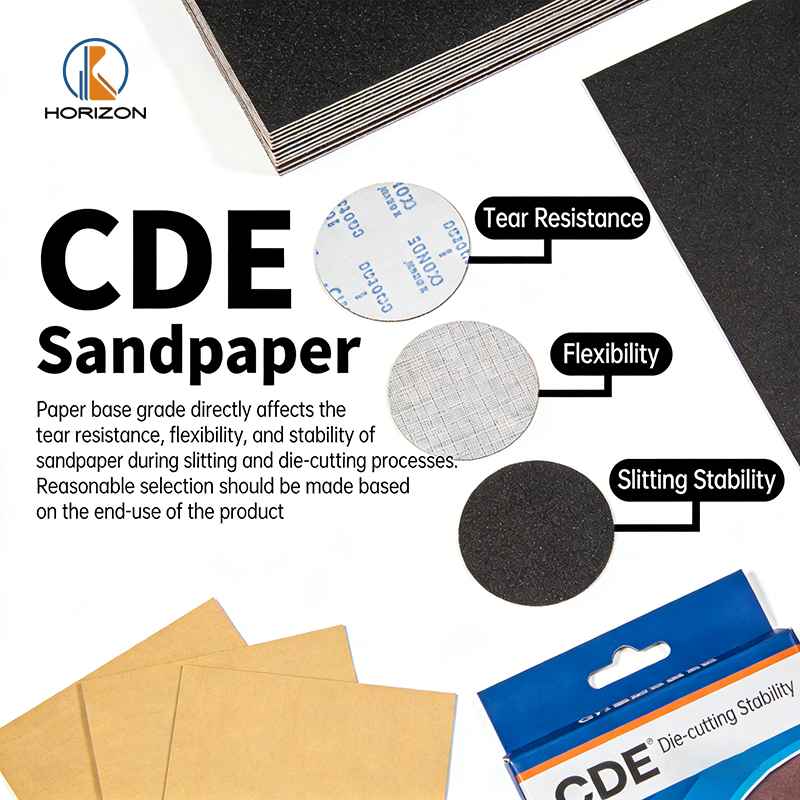

Backing Type & Machine Compatibility

Ensuring Disc Stability at High Speed

Backing type directly affects disc adhesion and operational safety and should be matched with machine speed and load.

Paper Backing

Lightweight and economical, suitable for medium to light sanding applications.

Film Backing

High dimensional stability, ideal for high-speed sanding and precision finishing.

————————————————————————————————————————————————————————————————————————————————————

Grit Selection by Sanding Stage

From Stock Removal to Final Finishing

- P40 – P80: Coarse sanding and rapid stock removal

- P100 – P180: Medium sanding and surface leveling

- P220 – P400: Fine sanding and coating preparation

- P600 – P3000: Fine finishing and surface refinement

————————————————————————————————————————————————————————————————————————————————————

Hole Pattern & Dust Extraction

Improving Surface Quality and Disc Life

Different hole patterns are available to match sander models and dust extraction systems, improving dust removal and reducing clogging.

- No holes

- 5-hole / 6-hole

- 8-hole

- Multi-hole (universal dust extraction patterns)

————————————————————————————————————————————————————————————————————————————————————

Compatible Machines & Applications

Designed for Professional Sanding Equipment

- Orbital sanders

- Random orbital sanders

- Furniture, woodworking, automotive refinishing, metal surface preparation

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Custom Hook & Loop Disc Manufacturing

We provide OEM and ODM customization for disc size, hole pattern, abrasive combination, and packaging, supporting bulk supply and long-term cooperation.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our Velcro Sanding Discs

Stable Adhesion, Consistent Quality and Factory Direct Supply

With reliable hook & loop adhesion technology, proven coating processes, and strict quality control, we deliver consistent sanding performance with low defect rates.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

Extend Disc Life and Performance

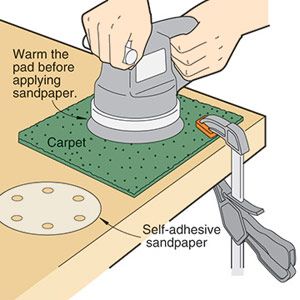

- Ensure backing pad is clean before use

- Do not exceed rated machine speed

- Store in dry conditions to prevent hook & loop degradation