Zirconia Sanding Belts (Zirconia Alumina Belts)

- Home

- Zirconia Sanding Belts (Zirconia Alumina Belts)

Categories

Zirconia Sanding Belts (Zirconia Alumina Belts)

Zirconia Sanding Belts (Zirconia Alumina Belts)

High-Load, Self-Sharpening Sanding Belts for Heavy Stock Removal

Zirconia abrasives feature a microcrystalline structure that continuously fractures under pressure to expose new cutting edges, creating a self-sharpening effect.

This allows the belt to maintain aggressive cutting performance under heavy loads while significantly extending usable life.

Product Description

Zirconia Sanding Belts (Zirconia Alumina Belts)

High-Load, Self-Sharpening Sanding Belts for Heavy Stock Removal

————————————————————————————————————————————————————————————————————————————————————

Technical Specifications

|

Item |

Specification |

| Abrasive |

Zirconia Alumina (ZA) |

|

Backing |

Heavy-duty X-weight / Y-weight Cloth |

| Grit Range |

P24 – P150 |

|

Joint Type |

Lap Joint / Butt Joint |

| Bonding |

Full Resin Bond (Resin over Resin) |

|

Dimensions |

Custom Sizes Available |

————————————————————————————————————————————————————————————————————————————————————

Product Positioning

Heavy-Duty Sanding Belts Beyond Standard Aluminum Oxide

Zirconia sanding belts are industrial belts designed for high load and high stock removal applications, offering a performance upgrade over standard aluminum oxide belts where efficiency and durability are critical.

————————————————————————————————————————————————————————————————————————————————————

Product Overview

Self-Sharpening Grain and Extended Belt Life

Zirconia abrasives feature a microcrystalline structure that continuously fractures under pressure to expose new cutting edges, creating a self-sharpening effect.

This allows the belt to maintain aggressive cutting performance under heavy loads while significantly extending usable life.

————————————————————————————————————————————————————————————————————————————————————

High Load Application Engineering

Designed for Pressure, Speed and Material Removal

Zirconia belts perform best under high contact pressure, heavy feed rates, and elevated belt speeds, making them ideal for continuous heavy grinding processes.

- Effective for large material removal

- Performs well under high feed pressure

- Outperforms aluminum oxide belts in heavy-load conditions

————————————————————————————————————————————————————————————————————————————————————

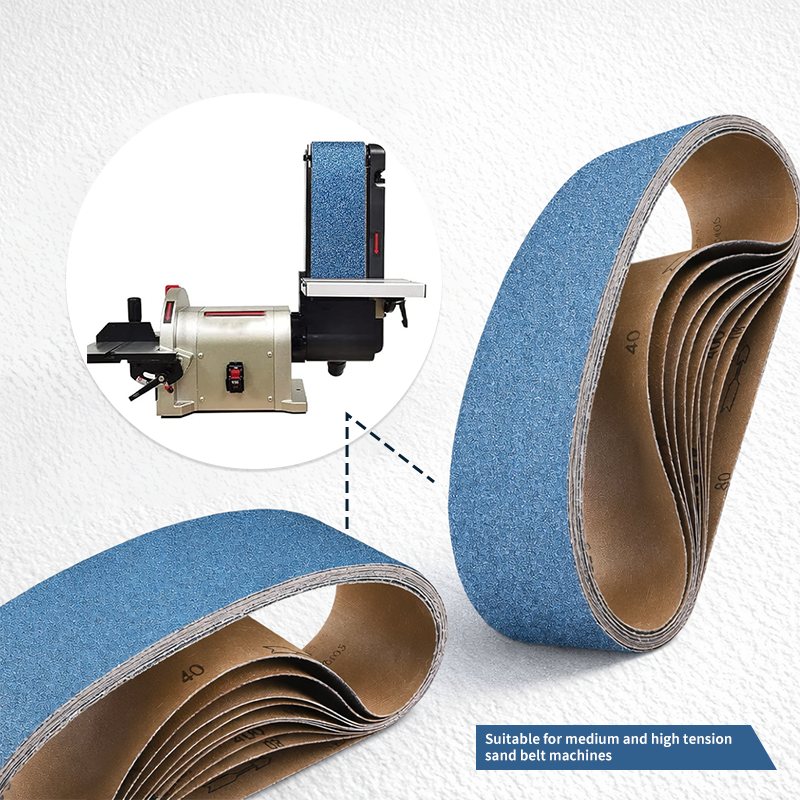

Backing Selection & Tension Compatibility

Ensuring Structural Stability Under Heavy Loads

X-weight cloth backing: Suitable for medium to high tension machines

Y-weight cloth backing: Designed for high-tension wide belt sanders

Backing strength is critical for preventing belt failure under heavy load conditions.

————————————————————————————————————————————————————————————————————————————————————

Tension, Speed & Self-Sharpening

Activating Zirconia Performance

Zirconia self-sharpening requires sufficient pressure and speed to activate:

- Low tension: Insufficient self-sharpening

- Low pressure: Grain polishing instead of fracturing

- Proper load: Continuous sharp cutting

————————————————————————————————————————————————————————————————————————————————————

Engineering Comparison with Aluminum Oxide Belts

|

Comparison |

Zirconia Belts | Aluminum Oxide Belts |

| Load capacity | ★★★★★ |

★★★ |

|

Self-sharpening |

Strong | Moderate |

| Service life | Long |

Medium |

|

Optimal conditions |

High pressure, heavy feed | Medium to low load |

| Cost | Higher |

Lower |

————————————————————————————————————————————————————————————————————————————————————

Typical Applications & Industries

- Heavy metal fabrication

- Weld removal and chamfering

- Industrial plate and structural component processing

————————————————————————————————————————————————————————————————————————————————————

Grit Range & Recommended Use

- P24 – P36: Heavy grinding and weld removal

- P40 – P80: Rapid material removal

- P100 – P150: Medium shaping

————————————————————————————————————————————————————————————————————————————————————

OEM & ODM Capability

Heavy-Duty Belt Customization

We provide OEM and ODM customization for zirconia belts based on machine load capacity, tension range, and process objectives, including backing grade, abrasive composition, splice structure, and dimensions.

————————————————————————————————————————————————————————————————————————————————————

Why Choose Our Zirconia Sanding Belts

Engineered for Heavy Grinding Stability

With proven heavy-duty belt manufacturing expertise, stable splicing technology, and strict quality control, we deliver high-efficiency, long-life grinding solutions.

————————————————————————————————————————————————————————————————————————————————————

Usage and Storage Recommendations

- Apply sufficient load during initial use to activate self-sharpening

- Avoid prolonged low-pressure polishing

- Store in dry, temperature-controlled conditions