Цилиндрические лепестковые круги

- Главная

- Цилиндрические лепестковые круги

Категории

Цилиндрические лепестковые круги

Обзор продукта

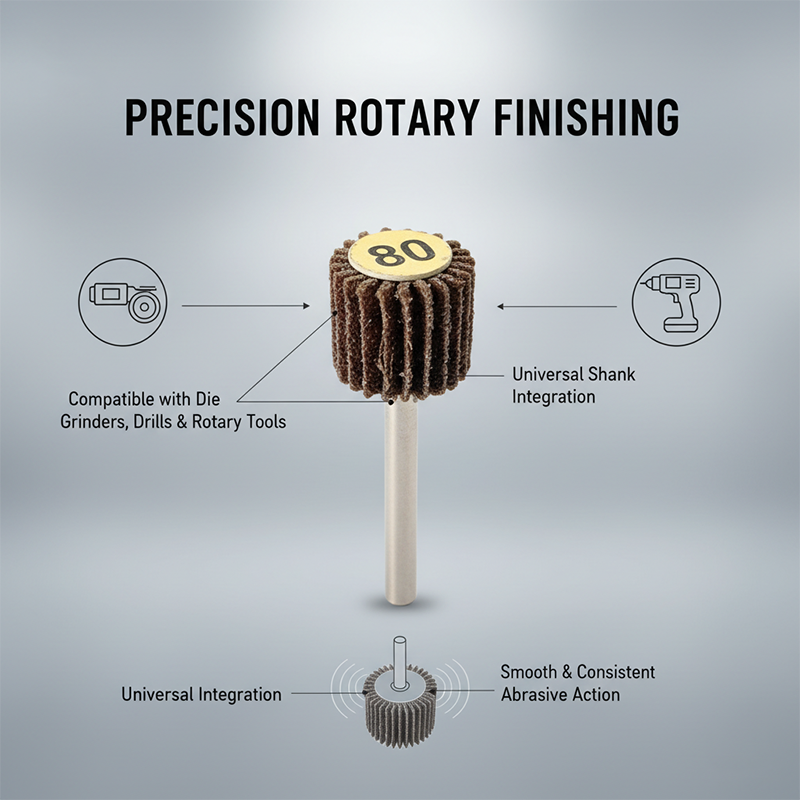

Радиальные лепестки на цилиндрическом сердечнике — для равномерного контакта и плавного блендинга

Цилиндрические лепестковые круги состоят из радиально расположенных абразивных лепестков вокруг цилиндрического сердечника и обычно устанавливаются через посадочное отверстие на финишные станки или специальные оправки.

Их «податливый» контакт обеспечивает снятие заусенцев, выравнивание риски, блендинг швов и доводку поверхности с хорошей «прощаемостью», не вызывая чрезмерного изменения размеров детали.

Описание продукта

Позиционирование продукта

Круги для финишной обработки плоскостей, наружных (OD) и внутренних (ID) диаметров

Цилиндрические лепестковые круги позиционируются как инструменты для доводки поверхности и блендинга с акцентом на равномерную риску и плавные переходы.

По сравнению с лепестковыми кругами на оправке они имеют большую площадь контакта и более ровный «ритм» процесса; по сравнению с лепестковыми дисками для УШМ лучше подходят для стабильной финишной обработки плоскостей, наружных (OD) и внутренних (ID) диаметров и профилированных поверхностей.

—————————————————————————————————————————————————————————————————————————————————————————-

Технические характеристики

Конфигурации по посадочному отверстию, ширине, плотности и абразивной системе

|

Параметр |

Спецификация |

|

Тип продукта |

Цилиндрические лепестковые круги |

| Абразив |

Варианты абразива: AO / zirconia / ceramic |

|

Конструкция |

Радиальная лепестковая конструкция |

| Наружный диаметр |

Наружный диаметр 3/4″–12″ (20–300 мм) (возможно расширение) |

|

Ширина |

Ширина 3/8″–8″ (10–200 мм) (возможно расширение) |

| Посадочное отверстие |

Посадочное отверстие 1/4″–2″ (на заказ) |

|

Диапазон зернистости |

P60–P240 (возможно расширение) |

| Макс. об/мин (Max RPM) |

Маркировка по размеру и стандарту |

—————————————————————————————————————————————————————————————————————————————————————————-

Логика обработки

Податливый радиальный контакт — для равномерной риски и плавных переходов

Цилиндрические лепестковые круги формируют стабильную текстуру за счёт податливого контакта:

- Лепестки подстраиваются под небольшую кривизну и профиль;

- Непрерывная работа множества лепестков даёт равномерную и контролируемую риску;

- Они сильны в блендинге и доводке, а не в тяжёлом съёме.

Поэтому их часто используют для блендинга после сварки, переходов под «сатин/шлифованный» финиш, снятия заусенцев и лёгкого притупления кромки.

—————————————————————————————————————————————————————————————————————————————————————————-

Конструкция основы и пределы применения

Финишная ориентация — не замена лентам или жёстким кругам

- Плюсы: Равномерный финиш, плавный блендинг, щадящий контакт с поверхностью

- Ограничения / пределы применения :Не для тяжёлого съёма и ударных режимов; для быстрого съёма используйте ленты или тяжёлые лепестковые круги/шлифкруги

Чрезмерный прижим или задержка на месте могут привести к перегреву и неравномерному износу — требуется стабильная подача

—————————————————————————————————————————————————————————————————————————————————————————-

Совместимость с оборудованием и условия работы

Круги с посадочным отверстием для финишных станков и производственной оснастки

- Оборудование: Финишные станки, полировально-шлифовальные машины, специальные оправки (установка через отверстие)

- Рекомендуемые условия: Средний–низкий прижим, стабильная окружная скорость, непрерывная подача

- Обязательно: Соответствие диаметра отверстия оправке, ширины круга и скоростного класса (не превышать Max RPM)

—————————————————————————————————————————————————————————————————————————————————————————-

Инженерное сравнение

|

Сравнение |

Цилиндрические лепестковые круги | Шлифовальные ленты | Нетканые круги |

| Способность к съёму материала | Низкий–средний | Высокая |

Низкая |

|

Стабильность риски |

Отличный | Хорошая (зависит от режимов) | Отличный |

| Блендинг | Отличный | Среднее–хорошее |

Отличный |

|

Влияние на размеры |

Низкая | Средний | Очень низкое |

| Типичное применение | Сатинирование/блендинг/снятие заусенцев | Выравнивание/съём |

Доводка/текстура |

—————————————————————————————————————————————————————————————————————————————————————————-

Типовые применения и отрасли

Стабильная финишная обработка металла, дерева и композитов

- Выравнивание «сатина» и блендинг на нержавейке/алюминии

- Блендинг швов, снятие заусенцев и лёгкое снятие фаски

- Доводка поверхности дерева/композитов (в зависимости от абразива)

- Непрерывная доводка фурнитуры, труб и профилей

—————————————————————————————————————————————————————————————————————————————————————————-

Диапазон зернистости и рекомендации по применению

Стратегия зернистости под финиш

Типовые рекомендации

- P60–P80: блендинг шва и поверхности (баланс)

- P100–P120: универсальное сатинирование и уточнение риски (самый распространённый)

- P150–P240: тонкий финиш, улучшение внешнего вида и исправление переделок

—————————————————————————————————————————————————————————————————————————————————————————-

Возможности OEM/ODM

Инженерная разработка кругов под производственный такт

OEM/ODM: стандарты наружного диаметра/ширины/посадки, плотность и жёсткость лепестков, угол укладки, абразивная система, материал сердечника и класс балансировки, упаковка и private label — инженерно под производственный такт и целевую текстуру.

—————————————————————————————————————————————————————————————————————————————————————————-

Почему выбирают нас

Равномерный финиш требует балансировки, стабильной укладки и контроля процесса

Для стабильного финиша необходимы: динамическая балансировка, равномерная укладка лепестков, контроль системы связки и стабильность партий.Балансировка влияет на вибрации и равномерность риски; укладка и связка задают кривую износа.Мы проектируем под производственную стабильность, чтобы финиш был воспроизводимым.

—————————————————————————————————————————————————————————————————————————————————————————-

Рекомендации по использованию и хранению

Лучший финиш достигается стабильной скоростью и подачей

- Не превышайте Max RPM; соблюдайте допустимые обороты и обеспечьте надёжный монтаж с правильной защитой

- Работайте со средним–низким прижимом и непрерывной подачей, чтобы избежать локального перегрева и неравномерного износа

- Для косметических деталей переходите по зернистостям ступенчато, чтобы уменьшить глубокую риску и переделки

- Храните в сухом месте в тени; избегайте влаги и сдавливания; после вскрытия повторно герметизируйте упаковку