Алмазные диски по бетону и кирпичной кладке

- Главная

- Алмазные диски по бетону и кирпичной кладке

Категории

Алмазные диски по бетону и кирпичной кладке

Позиционирование продукта

Jobsite heavy-load consumable—built for throughput, cooling, and anti-glazing under dust, heat, and variable aggregate

High-cooling, high-evacuation diamond blades for concrete & masonry—segmented rims and bond-grade matching deliver fast cutting and predictable life across aggregate types

Concrete/masonry cutting is dominated by abrasiveness, dust, and heat. Priorities are speed, continuity, heat resistance, and glazing resistance, with predictable life across variable aggregates. Unlike tile blades, throughput and robustness are primary; edge finish is secondary.

Описание продукта

Позиционирование продукта

Jobsite heavy-load consumable—built for throughput, cooling, and anti-glazing under dust, heat, and variable aggregate

Concrete/masonry cutting is dominated by abrasiveness, dust, and heat. Priorities are speed, continuity, heat resistance, and glazing resistance, with predictable life across variable aggregates. Unlike tile blades, throughput and robustness are primary; edge finish is secondary.

————————————————————————————————————————————————————————————————————————————————————

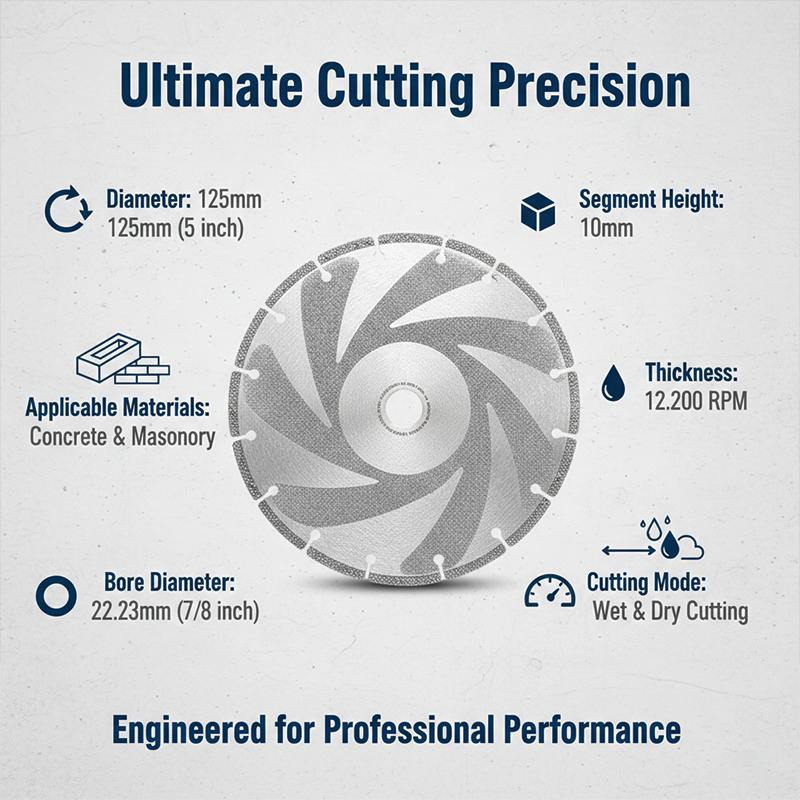

Технические характеристики

Three decisive levers: segmented/slot design, segment height, and bond grade (soft/medium/hard)

|

Спецификация |

Engineering Notes |

| Target Materials |

Concrete, brick, block, masonry (Asphalt requires specific bond formulas) |

|

Rim Type |

Primarily Segmented (best for cooling/debris removal); Turbo rim optional for specific apps |

| Slots/Cooling |

Efficient slotting improves heat & clog resistance while maintaining core strength |

|

Segment Height |

Higher segments usually mean longer life; must match tool power & cooling conditions |

| Bond Grade |

Selection based on aggregate abrasiveness, strength, and rebar presence |

|

Dry/Wet Cut |

Wet cutting offers superior thermal control; dry cutting requires dust & heat management |

| Rebar Suitability |

Requires a stable core, impact resistance, and enhanced thermal management |

————————————————————————————————————————————————————————————————————————————————————

Key Features

Anti-glazing, heat-resilient, aggregate-tolerant—keep cutting without burn-out or frequent stops

- High cooling/evacuation via segments and slots;

- Glazing resistance through bond/diamond matching;

- Stable plates reduce binding and abnormal wear;

- Tolerant to aggregate variability—bond grade matters most.

————————————————————————————————————————————————————————————————————————————————————

Логика обработки

Speed and life hinge on whether matrix wear stays synchronized with diamond consumption

- Bond too soft: abrasive aggregate consumes segments fast → short life;

- Bond too hard: diamonds don’t expose → glazing → speed collapse;

- Uncontrolled heat in dry heavy cutting causes thermal degradation;

- Rebar introduces impact and instability—requires stable plates and conservative feed.

————————————————————————————————————————————————————————————————————————————————————

Machine Compatibility

Grinders, cut-off saws, floor saws—more stable power/RPM better leverages higher segments and life-focused designs

- Angle grinders: rely on operator control and dust extraction—segmented rims preferred;

- Cut-off/bench saws: stable feed supports higher segments for life;

- Floor saws: wet cutting and correct bond grade are critical.

————————————————————————————————————————————————————————————————————————————————————

Инженерное сравнение

Segmented vs turbo—segmented runs coolest and resists glazing; turbo balances; continuous is generally not for heavy dry cutting

- Segmented: best cooling/evacuation for dry cutting and throughput;

- Turbo: smoother cutting with balanced performance;

- Continuous: generally prone to heat build-up in heavy dry concrete work.

————————————————————————————————————————————————————————————————————————————————————

Типовые применения и отрасли

Construction, MEP chasing, masonry cutting, renovation/demolition, and municipal maintenance

Cutting concrete walls/floors, chasing masonry blocks, jobsite trimming, and renovation cuts.

————————————————————————————————————————————————————————————————————————————————————

Диапазон и рекомендуемое применение

4-step selection: aggregate abrasiveness → rebar risk → dry/wet → segment height and slot/cooling design

- Dry cutting: segmented + strong cooling slots + dust extraction;

- High rebar probability: prioritize stable plates and conservative technique;

- One-line rule: Concrete is about aggregate and heat—more abrasive aggregate needs tougher bond; dry cutting demands dust and heat control.

————————————————————————————————————————————————————————————————————————————————————

Customization (OEM/ODM)

OEM/ODM by aggregate abrasiveness, rebar risk, and dry/wet use—bond grade, segment height and cooling structure

OEM/ODM:

Diameter, arbor, segment height/thickness, segment geometry and gullets, slot design, bond grades, diamond system, private label packaging and assortments.

————————————————————————————————————————————————————————————————————————————————————

Почему выбирают нас

We build SKUs around aggregate-abrasiveness mapping—turn bond grade into actionable selection logic, reducing glazing and premature wear

Most failures come from mismatch, not defects. We help define reusable bond-grade systems and selection guides aligned to your market’s typical conditions, reducing misuse and returns.

————————————————————————————————————————————————————————————————————————————————————

Рекомендации по использованию и хранению

Dry-cut essentials: dust extraction, intermittent feed, avoid side load—plus silica exposure control

- Use shroud + extractor to control silica dust;

- Intermittent cutting manages heat;

- Avoid side pressure to prevent binding and plate damage;

- Rebar contact: conservative feed and stable RPM;

- Store dry and protect from impacts/deformation.