Exploring Different Sandpaper Types for Jewelry Making

When it comes to jewelry making, achieving a smooth and polished finish is essential. One of the most effective tools for achieving this is sandpaper. Sandpaper, also known as abrasive paper, is a versatile tool that can be used to shape, smooth, and polish various materials, including metals, gemstones, and even glass. In this article, we will explore different types of sandpaper that are commonly used in jewelry making, their characteristics, and how to choose the right sandpaper for your specific needs.

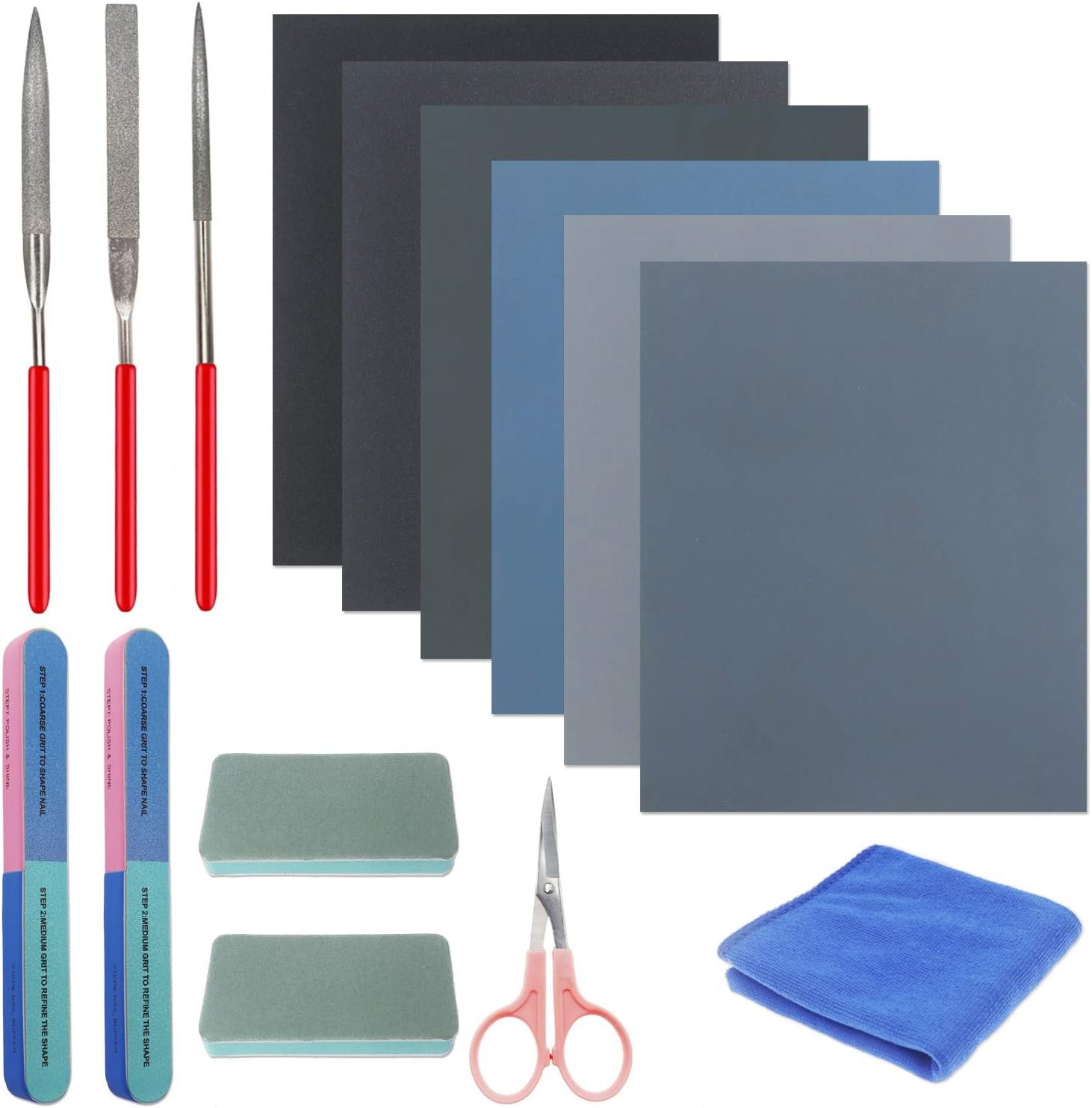

Best Sandpaper for Jewelry

Jewelry Sandpaper

Jewelry Cleaning Kit

Product Features

1. Understanding Grit

Grit is a term used to describe the coarseness or fineness of sandpaper. It refers to the number of abrasive particles per square inch on the sandpaper’s surface. The higher the grit number, the finer the sandpaper. Grit numbers typically range from 40 to 2000, with lower numbers being coarser and higher numbers being finer.

For jewelry making, it is important to have a variety of sandpaper grits on hand to accommodate different stages of the jewelry making process. Coarse grit sandpaper, such as 40 or 60 grit, is ideal for shaping and removing excess material. Medium grit sandpaper, ranging from 80 to 120 grit, is suitable for smoothing and refining the surface. Fine grit sandpaper, around 220 to 400 grit, is used for polishing and achieving a smooth finish. Extra fine grit sandpaper, above 400 grit, is used for final polishing and achieving a mirror-like shine.

2. Types of Sandpaper

2.1 Silicon Carbide Sandpaper

Silicon carbide sandpaper is one of the most commonly used types of sandpaper in jewelry making. It is known for its durability and ability to cut through hard materials, such as metal and gemstones. Silicon carbide sandpaper is available in various grits, ranging from coarse to fine. It is particularly effective for shaping and smoothing metal surfaces, as well as removing scratches and imperfections.

2.2 Aluminum Oxide Sandpaper

Aluminum oxide sandpaper is another popular choice for jewelry making. It is known for its versatility and ability to work on a wide range of materials, including metal, wood, and glass. Aluminum oxide sandpaper is available in different grits, making it suitable for various stages of the jewelry making process. It is particularly effective for smoothing and polishing metal surfaces, as well as removing rust and corrosion.

2.3 Garnet Sandpaper

Garnet sandpaper is a natural abrasive that is often used for woodworking and metalworking. It is known for its sharpness and ability to produce a smooth finish. Garnet sandpaper is available in different grits, ranging from coarse to fine. It is particularly effective for shaping and smoothing wood surfaces, as well as removing old finishes and paint.

3. Choosing the Right Sandpaper

When choosing sandpaper for jewelry making, it is important to consider the material you are working with and the desired outcome. Here are some factors to consider:

3.1 Material

Different materials require different types of sandpaper. For example, if you are working with metal, silicon carbide or aluminum oxide sandpaper would be suitable. If you are working with wood, garnet sandpaper would be a good choice. Consider the hardness and texture of the material to determine the appropriate sandpaper.

3.2 Grit

Consider the stage of the jewelry making process and the level of smoothness you want to achieve. Coarse grit sandpaper is ideal for shaping and removing excess material, while fine grit sandpaper is suitable for polishing and achieving a smooth finish. Having a variety of grits on hand will allow you to work through different stages efficiently.

3.3 Wet or Dry Sanding

Some sandpapers are designed for wet sanding, which involves using water or a lubricant to reduce friction and prevent clogging. Wet sanding is particularly effective for achieving a smooth and polished finish. Dry sanding, on the other hand, is suitable for rough shaping and removing material. Consider the specific requirements of your jewelry making project to determine whether wet or dry sanding is more appropriate.

4. Tips for Using Sandpaper

Using sandpaper effectively requires proper technique and care. Here are some tips to keep in mind:

4.1 Use a Sanding Block

Using a sanding block can help distribute pressure evenly and prevent uneven sanding. It also provides a flat surface for more precise sanding. Choose a sanding block that is comfortable to hold and fits the size of the sandpaper.

4.2 Start with Coarse Grit

If you are shaping or removing excess material, start with a coarse grit sandpaper and gradually work your way up to finer grits. This will help you achieve a smoother finish and prevent unnecessary scratches or damage.

4.3 Sand in One Direction

When sanding, it is important to sand in one direction to achieve a consistent finish. Sanding back and forth can create uneven scratches and make it difficult to achieve a smooth surface.

4.4 Use Light Pressure

Applying too much pressure while sanding can cause the sandpaper to wear out quickly and may result in uneven sanding. Use light, even pressure and let the sandpaper do the work.

5. Conclusion

Sandpaper is an essential tool for jewelry making, allowing you to shape, smooth, and polish various materials. Understanding the different types of sandpaper and their characteristics is crucial for achieving the desired finish. Whether you are working with metal, wood, or glass, choosing the right sandpaper and using proper technique will help you create stunning jewelry pieces. Remember to consider the material, grit, and wet or dry sanding requirements when selecting sandpaper for your projects. With the right sandpaper and technique, you can take your jewelry making skills to the next level.