Factors to Consider When Buying Sandpaper for Jewelry

When it comes to jewelry making, sandpaper is an essential tool that can help you achieve a smooth and polished finish on your creations. Whether you are working with metal, wood, or glass, choosing the right sandpaper can make a significant difference in the quality of your final product. However, with so many options available in the market, it can be overwhelming to select the best sandpaper for your specific needs. In this article, we will explore the factors you should consider when buying sandpaper for jewelry, including the different types of sandpaper, grit sizes, backing materials, and more.

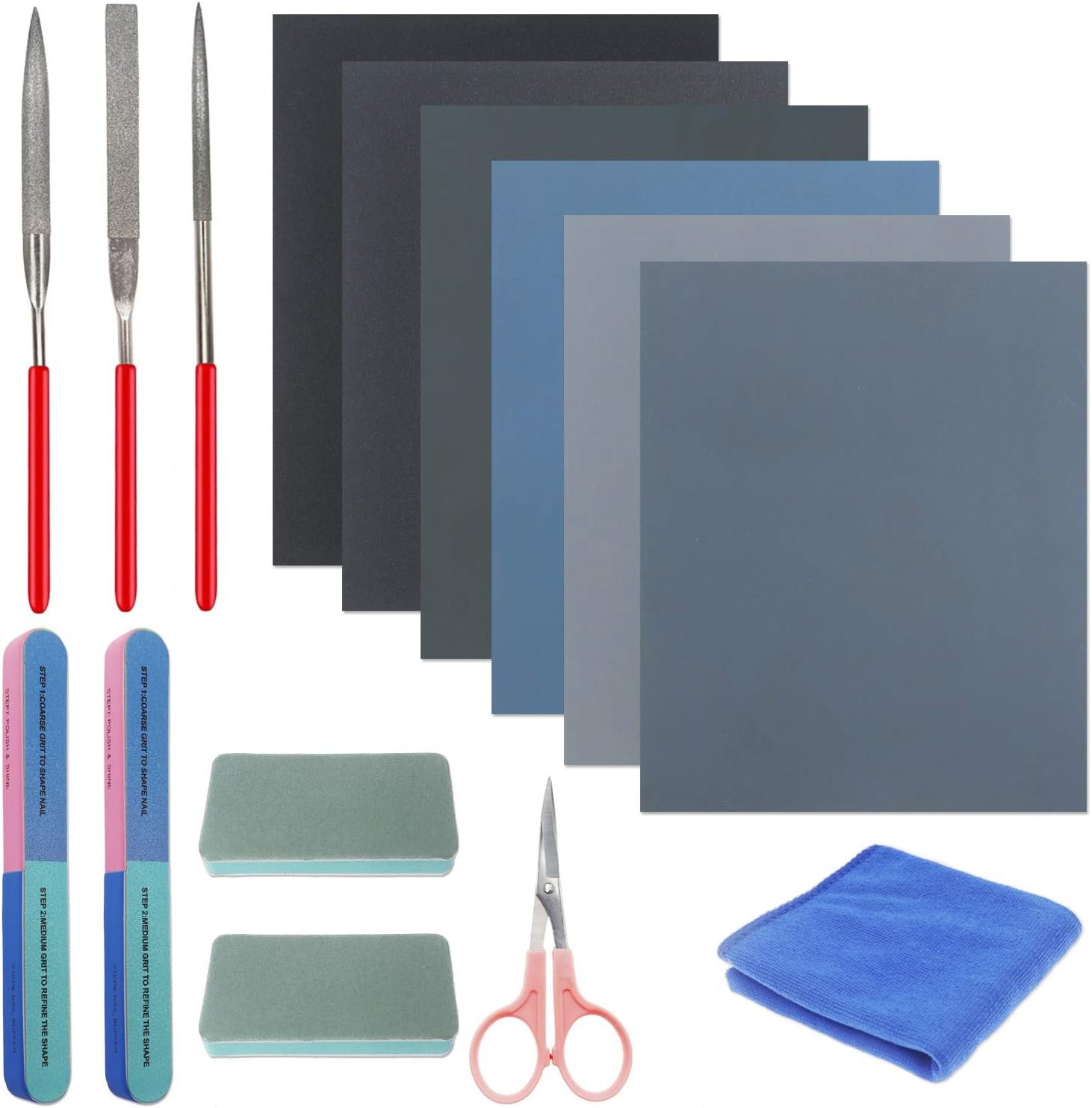

Best Sandpaper for Jewelry

Jewelry Sandpaper

Jewelry Cleaning Kit

Product Features

Types of Sandpaper

Before diving into the factors to consider, it is important to understand the different types of sandpaper available. Each type has its own unique characteristics and is designed for specific applications. Here are some common types of sandpaper:

- Abrasive Paper: This is a general term used to describe any type of sandpaper that contains abrasive particles.

- Sandpaper Sheets: These are large sheets of sandpaper that can be cut into smaller pieces for various applications.

- Sanding Blocks: These are blocks made of foam or rubber that are used to hold sandpaper securely in place.

- Sandpaper Roll: This is a continuous roll of sandpaper that can be cut to the desired length.

- Sandpaper Discs: These are circular discs that can be attached to power tools such as sanders or grinders.

- Sandpaper Sponge: This is a sponge with sandpaper attached to one side, providing flexibility and ease of use.

Grit Sizes

One of the most important factors to consider when buying sandpaper is the grit size. Grit refers to the size of the abrasive particles on the sandpaper, and it determines how coarse or fine the sandpaper is. The grit size is usually indicated by a number, with higher numbers representing finer grits. Here are some common grit sizes and their recommended uses:

- Coarse Grit Sandpaper (40-60 grit): This type of sandpaper is ideal for removing heavy material, such as paint or rust, from metal surfaces.

- Medium Grit Sandpaper (80-120 grit): This grit size is suitable for smoothing rough surfaces and preparing them for further finishing.

- Fine Grit Sandpaper (150-180 grit): Fine grit sandpaper is used for sanding between coats of paint or varnish to achieve a smooth finish.

- Extra Fine Grit Sandpaper (220-400 grit): This grit size is perfect for final sanding and polishing of jewelry pieces.

Backing Materials

The backing material of sandpaper plays a crucial role in its performance and durability. There are several types of backing materials available, each with its own advantages and disadvantages. Here are some common backing materials used in sandpaper:

- Aluminum Oxide Sandpaper: This is the most commonly used backing material and is suitable for a wide range of applications. It is durable and can be used on both metal and wood surfaces.

- Silicon Carbide Sandpaper: This backing material is ideal for sanding hard materials such as glass or stone. It is also commonly used for wet sanding.

- Garnet Sandpaper: Garnet sandpaper is a natural abrasive that is gentle on delicate surfaces. It is often used for sanding wood and is less aggressive than aluminum oxide or silicon carbide.

- Waterproof Sandpaper: As the name suggests, this type of sandpaper is designed to be used with water or other liquids. It is commonly used for wet sanding and is more durable than regular sandpaper.

Application

Another important factor to consider when buying sandpaper for jewelry is the specific application you will be using it for. Different materials and projects require different types of sandpaper. For example, if you are working with metal, you may need a more aggressive sandpaper to remove scratches or imperfections. On the other hand, if you are working with delicate gemstones, you will need a finer grit sandpaper to avoid damaging the surface. It is essential to assess your specific needs and choose the appropriate sandpaper accordingly.

Quality and Durability

When purchasing sandpaper for jewelry making, it is crucial to consider the quality and durability of the product. Low-quality sandpaper may wear out quickly or lose its abrasive properties, resulting in a poor finish. Look for reputable brands that are known for their quality products. Reading customer reviews and checking for certifications can also help you determine the reliability of the sandpaper.

Cost

Cost is another factor to consider when buying sandpaper for jewelry. While it is tempting to opt for the cheapest option available, it is important to remember that quality and performance should be prioritized over cost. Investing in high-quality sandpaper may cost more initially, but it will save you time and money in the long run by providing better results and lasting longer.

Conclusion

Choosing the right sandpaper for jewelry making is essential for achieving a professional and polished finish. By considering factors such as the type of sandpaper, grit size, backing material, application, quality, and cost, you can make an informed decision and select the best sandpaper for your specific needs. Remember to assess your project requirements and choose the appropriate sandpaper accordingly. With the right sandpaper in hand, you can take your jewelry making skills to the next level and create stunning pieces that will impress your customers.