The Effect of Sandpaper Choice on Jewelry Finishing

When it comes to jewelry finishing, the choice of sandpaper plays a crucial role in achieving the desired results. Whether you are a professional jeweler or a hobbyist, understanding the different types of sandpaper and their specific uses can greatly enhance the quality of your work. In this article, we will explore the various factors to consider when selecting sandpaper for jewelry finishing, the different types of sandpaper available, and how to use them effectively.

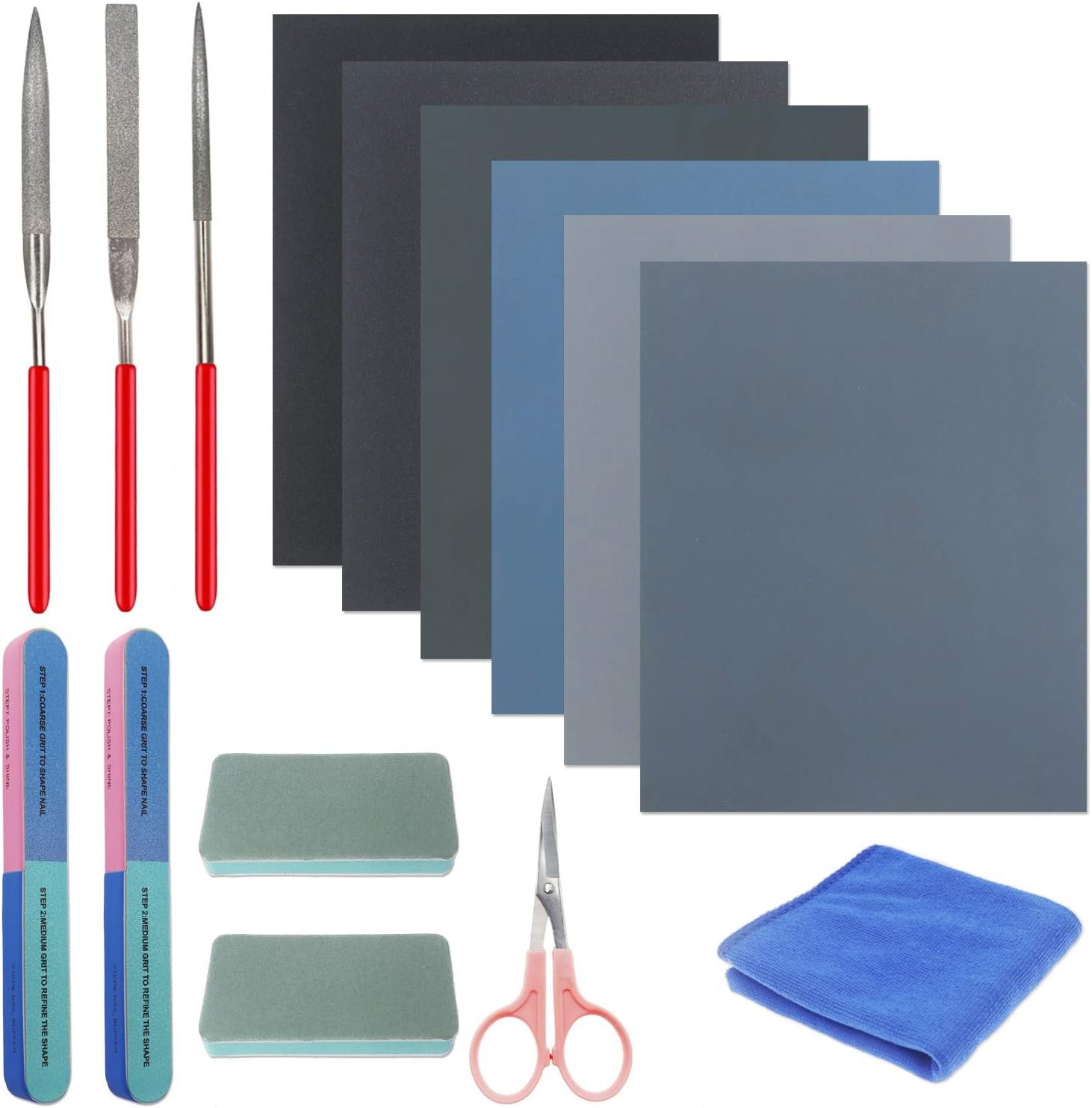

Best Sandpaper for Jewelry

Jewelry Sandpaper

Jewelry Cleaning Kit

Product Features

Factors to Consider when Selecting Sandpaper

Before delving into the different types of sandpaper, it is important to understand the factors that should influence your choice. These factors include:

- Grit Size

- Material Compatibility

- Surface Finish

- Wet or Dry Sanding

Grit Size

The grit size of sandpaper refers to the number of abrasive particles per square inch. It determines the coarseness or fineness of the sandpaper and plays a significant role in the rate of material removal. The higher the grit number, the finer the sandpaper. For jewelry finishing, it is important to consider the level of surface refinement required. Fine grit sandpaper, such as 400 to 600 grit, is ideal for achieving a smooth and polished finish on delicate jewelry pieces. Coarse grit sandpaper, on the other hand, is better suited for removing larger imperfections or shaping metal.

Material Compatibility

Another important factor to consider when selecting sandpaper for jewelry finishing is material compatibility. Different metals and gemstones have varying hardness levels, and using the wrong sandpaper can result in scratches or damage to the jewelry piece. It is essential to choose sandpaper that is specifically designed for the material you are working with. For example, silicon carbide sandpaper is ideal for sanding metals like stainless steel and aluminum, while garnet sandpaper is better suited for softer materials like wood and plastic.

Surface Finish

The desired surface finish also plays a role in determining the type of sandpaper to use. If you are looking for a smooth and polished finish, fine grit sandpaper is the way to go. However, if you want to achieve a textured or matte finish, a coarser grit sandpaper may be more suitable. It is important to experiment with different grit sizes and techniques to achieve the desired surface finish for your jewelry piece.

Wet or Dry Sanding

Depending on the material and the desired outcome, you may need to choose between wet or dry sanding. Wet sanding involves using water or a lubricant to reduce friction and prevent clogging of the sandpaper. It is particularly useful for working with soft metals and delicate gemstones, as it helps to prevent overheating and damage. Dry sanding, on the other hand, is suitable for harder materials and can be more efficient for removing larger imperfections.

Types of Sandpaper for Jewelry Finishing

Now that we have discussed the factors to consider when selecting sandpaper, let’s explore the different types of sandpaper available for jewelry finishing:

1. Aluminum Oxide Sandpaper

Aluminum oxide sandpaper is one of the most commonly used types of sandpaper for jewelry finishing. It is versatile and can be used on a wide range of materials, including metals, wood, and plastics. Aluminum oxide sandpaper is available in various grit sizes, making it suitable for both rough shaping and fine polishing.

2. Silicon Carbide Sandpaper

Silicon carbide sandpaper is known for its exceptional hardness and durability. It is particularly effective for sanding hard metals like stainless steel and titanium. Silicon carbide sandpaper is available in both wet and dry forms, making it suitable for a variety of jewelry finishing applications.

3. Garnet Sandpaper

Garnet sandpaper is a natural abrasive that is ideal for sanding softer materials like wood and plastic. It is less aggressive than aluminum oxide or silicon carbide sandpaper, making it suitable for delicate jewelry pieces. Garnet sandpaper is available in various grit sizes and can be used for both rough shaping and fine finishing.

4. Wet Dry Sandpaper

As the name suggests, wet dry sandpaper can be used for both wet and dry sanding applications. It is particularly useful for jewelry finishing, as it can be used to achieve a smooth and polished finish on a variety of materials. Wet dry sandpaper is available in different grit sizes and can be used with water or a lubricant for wet sanding.

Using Sandpaper Effectively

Now that we have explored the different types of sandpaper available for jewelry finishing, let’s discuss some tips for using sandpaper effectively:

1. Start with a Coarse Grit

If you are working on a jewelry piece that requires shaping or removing larger imperfections, start with a coarse grit sandpaper. This will help you achieve the desired shape and remove any unwanted material quickly. Once you have achieved the desired shape, gradually move to finer grits for smoothing and polishing.

2. Use Light Pressure

When sanding jewelry, it is important to use light pressure to avoid damaging the piece. Applying too much pressure can result in scratches or uneven surfaces. Let the sandpaper do the work and allow the abrasive particles to remove the material gradually.

3. Change Sandpaper Regularly

As you sand, the sandpaper can become clogged with debris, reducing its effectiveness. It is important to change the sandpaper regularly to ensure optimal performance. A clogged sandpaper can also cause scratches or leave unwanted marks on the jewelry piece.

4. Use a Sanding Block

Using a sanding block can help distribute the pressure evenly and prevent uneven sanding. It also provides a flat surface for sanding, ensuring a consistent finish. A sanding block can be particularly useful when working on larger jewelry pieces or when shaping metal.

Conclusion

The choice of sandpaper plays a crucial role in achieving the desired finish in jewelry finishing. By considering factors such as grit size, material compatibility, surface finish, and wet or dry sanding, you can select the most appropriate sandpaper for your specific needs. Whether you are shaping metal, removing imperfections, or achieving a smooth and polished finish, choosing the right sandpaper will greatly enhance the quality of your jewelry work. Remember to experiment with different grit sizes and techniques to achieve the desired results, and always use light pressure to avoid damaging the jewelry piece. With the right sandpaper and proper technique, you can take your jewelry finishing skills to the next level.