Pros and Cons of Various Sandpaper Types for Jewelry Work

Sandpaper is an essential tool for jewelry work, allowing artisans to shape, smooth, and polish their creations. However, with a wide range of sandpaper types available, it can be challenging to determine which one is best suited for specific jewelry projects. In this article, we will explore the pros and cons of various sandpaper types commonly used in jewelry work, including abrasive paper, sandpaper sheets, sanding blocks, and more. By understanding the characteristics of each type, jewelers can make informed decisions and achieve the desired results.

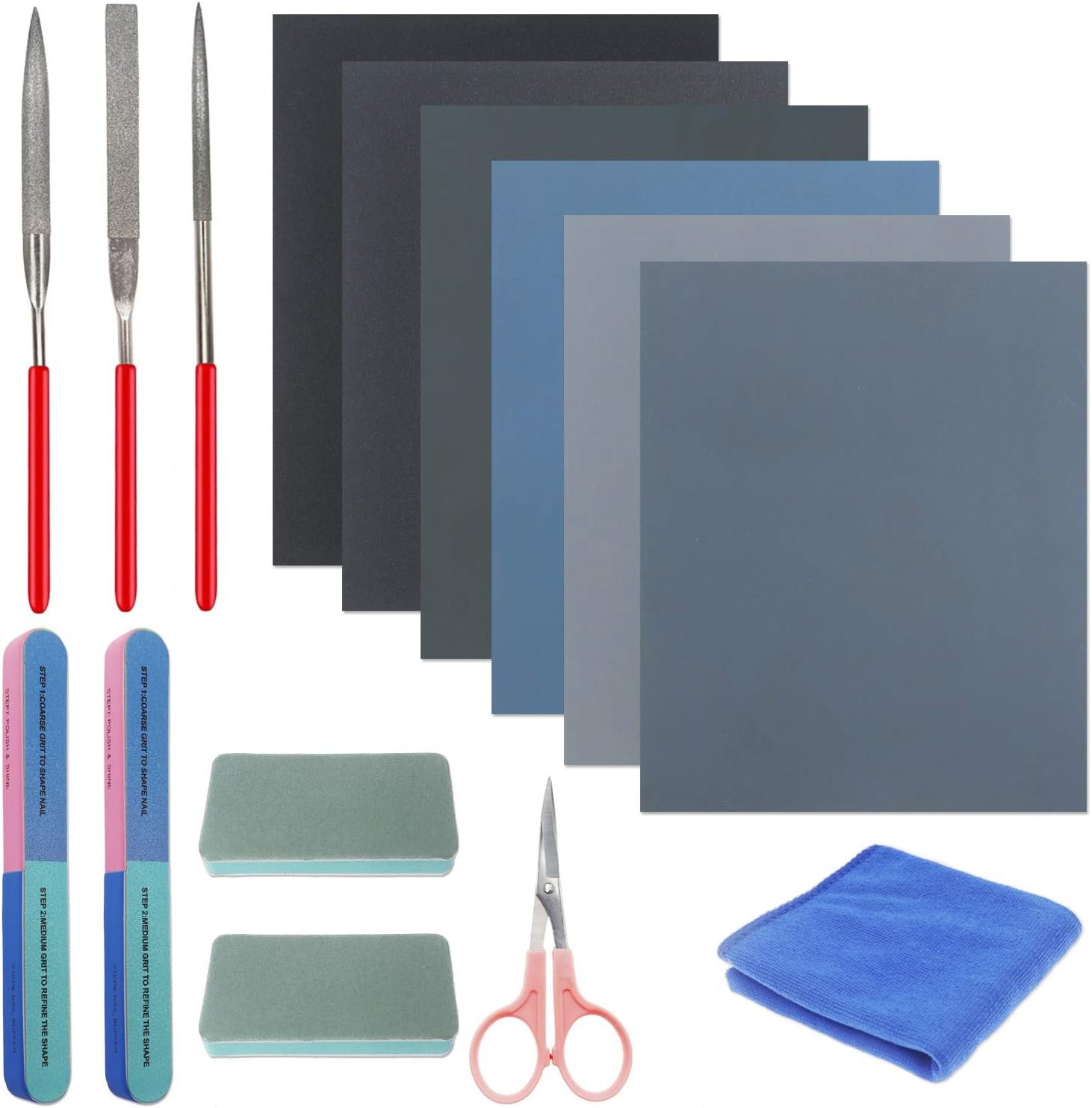

Best Sandpaper for Jewelry

Jewelry Sandpaper

Jewelry Cleaning Kit

Product Features

Abrasive Paper

Abrasive paper, also known as sandpaper, is a versatile option for jewelry work. It consists of a backing material coated with abrasive particles, such as silicon carbide or aluminum oxide. Abrasive paper is available in various grit sizes, which determine its coarseness or fineness. Here are the pros and cons of using abrasive paper for jewelry work:

Pros:

- Abrasive paper is widely accessible and affordable, making it a cost-effective choice for jewelers.

- It is available in different grit sizes, allowing jewelers to achieve the desired level of smoothness and polish.

- Abrasive paper can be used on various jewelry materials, including metals, wood, and glass.

- It is suitable for both wet and dry sanding, providing flexibility in different jewelry projects.

Cons:

- Abrasive paper may wear out quickly, especially when used on harder materials, requiring frequent replacements.

- Using abrasive paper with a coarse grit size can leave visible scratches on jewelry surfaces, requiring additional polishing steps.

- It may not be suitable for intricate jewelry designs or delicate gemstones, as it can remove material quickly.

Sandpaper Sheets

Sandpaper sheets are another popular option for jewelry work. They are typically sold in large rectangular sheets and can be easily cut into smaller pieces for specific projects. Here are the pros and cons of using sandpaper sheets for jewelry work:

Pros:

- Sandpaper sheets offer a large surface area, allowing jewelers to work on multiple pieces or larger jewelry items.

- They are available in various grit sizes, providing versatility for different stages of jewelry making.

- Sandpaper sheets can be easily folded or wrapped around sanding blocks or other tools, enhancing control and precision.

- They are suitable for both hand sanding and use with power tools, such as orbital sanders or belt sanders.

Cons:

- Using sandpaper sheets without proper support, such as a sanding block, can result in uneven sanding and potential damage to jewelry surfaces.

- They may require frequent replacements, especially when used on harder materials or for extensive sanding.

- Sandpaper sheets can be challenging to store and organize, as they tend to curl or become damaged if not properly protected.

Sanding Blocks

Sanding blocks are tools designed to hold sandpaper securely and provide a stable surface for sanding. They come in various shapes and sizes, including rectangular blocks, foam blocks, and sponge blocks. Here are the pros and cons of using sanding blocks for jewelry work:

Pros:

- Sanding blocks offer stability and control, ensuring even sanding and preventing accidental damage to jewelry surfaces.

- They can be used with different types of sandpaper, including sheets, rolls, and discs, providing versatility for various jewelry projects.

- Sanding blocks with foam or sponge surfaces can conform to curved or irregular jewelry shapes, allowing for precise sanding.

- They are reusable and durable, making them a long-term investment for jewelers.

Cons:

- Sanding blocks may require additional storage space compared to individual sheets or rolls of sandpaper.

- Using sanding blocks with worn-out or damaged sandpaper can result in uneven sanding and potential scratches on jewelry surfaces.

- Some sanding blocks may not be suitable for wet sanding, limiting their use in certain jewelry projects.

Silicon Carbide Sandpaper

Silicon carbide sandpaper is a popular choice for jewelry work due to its excellent cutting ability and durability. It is commonly used for shaping and smoothing metal surfaces. Here are the pros and cons of using silicon carbide sandpaper for jewelry work:

Pros:

- Silicon carbide sandpaper is highly effective in removing material quickly, making it ideal for shaping jewelry pieces.

- It is available in various grit sizes, allowing jewelers to achieve different levels of smoothness and surface finish.

- Silicon carbide sandpaper is durable and long-lasting, reducing the need for frequent replacements.

- It can be used for both wet and dry sanding, providing flexibility in different jewelry projects.

Cons:

- Using silicon carbide sandpaper with a coarse grit size can leave deep scratches on jewelry surfaces, requiring additional polishing steps.

- It may not be suitable for delicate gemstones or intricate jewelry designs, as it can remove material quickly.

- Silicon carbide sandpaper tends to be more expensive compared to other types of sandpaper.

Conclusion

Choosing the right sandpaper type for jewelry work is crucial for achieving desired results. While abrasive paper, sandpaper sheets, sanding blocks, and silicon carbide sandpaper all have their pros and cons, jewelers should consider the specific requirements of their projects and materials. For general jewelry work, abrasive paper and sandpaper sheets offer versatility and affordability. Sanding blocks provide stability and control, while silicon carbide sandpaper excels in shaping and smoothing metal surfaces. By understanding the characteristics of each sandpaper type, jewelers can make informed decisions and enhance their jewelry-making process.