Sanding stone is an essential process in various industries, including construction, sculpture, and jewelry making. It involves smoothing and shaping rough surfaces to achieve a desired finish. Whether you are working with natural stone, such as granite or marble, or artificial stone, like concrete or terrazzo, understanding the basics of sanding stone is crucial for achieving professional results. In this article, we will explore the tools, techniques, and sandpaper types used in the process of sanding stone.

The Best Sandpaper for Stone

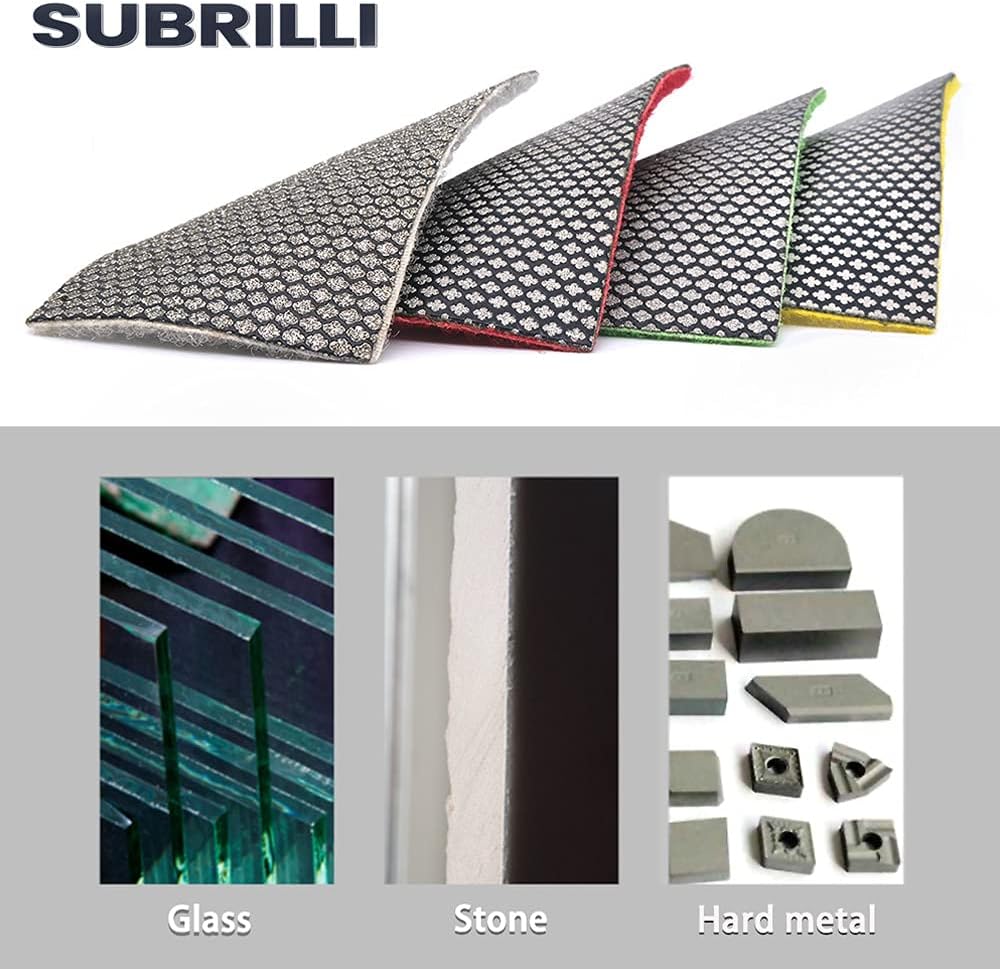

SUBRILLI Diamond Sandpaper 2-Pack

BLACK+DECKER 2.0 Amp Electric 1/4 Sheet Orbit Sander

Aouker HS85180 Hand Sander

Tools for Sanding Stone

Before diving into the sandpaper types, let’s first discuss the tools you will need for sanding stone. These tools are designed to remove material from the surface, creating a smooth and even finish. Here are some commonly used tools:

- Sanding Blocks: Sanding blocks are handheld tools that provide a stable surface for sanding. They come in various shapes and sizes, allowing you to reach different areas of the stone.

- Orbital Sander: An orbital sander is a power tool that uses a circular motion to sand the surface. It is particularly useful for larger areas and can be fitted with different grit sandpaper discs.

- Belt Sander: A belt sander is another power tool that uses a continuous loop of sandpaper to sand the surface. It is ideal for removing larger amounts of material quickly.

- Drum Sander: A drum sander is a heavy-duty tool commonly used for sanding wooden floors. It consists of a rotating drum covered in sandpaper, which can be adjusted to different grits.

- Sandpaper Sponge: A sandpaper sponge is a versatile tool that combines the flexibility of a sponge with the abrasive properties of sandpaper. It is great for sanding curved or irregular surfaces.

Techniques for Sanding Stone

Now that you are familiar with the tools, let’s explore some techniques for sanding stone. These techniques will help you achieve the desired finish while minimizing the risk of damaging the stone:

- Start with Coarse Grit Sandpaper: When sanding stone, it is important to start with a coarse grit sandpaper to remove any rough or uneven areas. This will help you achieve a smooth and level surface.

- Use Light Pressure: Applying too much pressure while sanding can cause the sandpaper to dig into the stone, leaving deep scratches. Instead, use light pressure and let the sandpaper do the work.

- Sand in a Circular Motion: Sanding in a circular motion helps to evenly distribute the pressure and prevent the formation of grooves. It also allows you to cover a larger area more efficiently.

- Change Direction: After sanding in a circular motion, change the direction to a back-and-forth or side-to-side motion. This will help remove any circular scratches and create a smoother finish.

- Progress to Finer Grits: As you sand the stone, gradually progress to finer grit sandpaper. This will help refine the surface and remove any remaining scratches from the previous grit.

- Wet Sanding: Wet sanding involves using water or a lubricant to reduce friction and prevent the sandpaper from clogging. It is particularly useful for softer stones, such as marble or limestone.

Sandpaper Types for Sanding Stone

Now that you understand the tools and techniques, let’s explore the different sandpaper types used for sanding stone. The choice of sandpaper depends on the type of stone, the desired finish, and the level of abrasiveness required. Here are some commonly used sandpaper types:

- Silicon Carbide Sandpaper: Silicon carbide sandpaper is a popular choice for sanding stone due to its high cutting power. It is available in various grits and is particularly effective for removing material quickly.

- Aluminum Oxide Sandpaper: Aluminum oxide sandpaper is another commonly used option for sanding stone. It is durable and provides a consistent finish. It is available in different grits for various sanding applications.

- Garnet Sandpaper: Garnet sandpaper is a natural abrasive that is often used for sanding wood. However, it can also be used for sanding stone, especially softer stones like limestone or sandstone.

- Waterproof Sandpaper: Waterproof sandpaper is designed to be used with water or a lubricant. It is particularly useful for wet sanding stone, as it resists clogging and provides a smooth finish.

Conclusion

Sanding stone is a fundamental process in various industries, and understanding the basics is essential for achieving professional results. By using the right tools, employing the correct techniques, and choosing the appropriate sandpaper types, you can achieve a smooth and even finish on any stone surface. Whether you are working with natural stone or artificial stone, the principles of sanding remain the same. Remember to start with a coarse grit sandpaper, use light pressure, and progress to finer grits for a refined finish. Experiment with different sandpaper types to find the one that works best for your specific application. With practice and patience, you can master the art of sanding stone and create stunning results.