How to Achieve the Perfect Shine: Best Sandpapers for Jewelry Polishing

When it comes to jewelry polishing, achieving the perfect shine is essential. Whether you are a professional jeweler or a hobbyist, using the right sandpaper can make all the difference in the final result. In this article, we will explore the best sandpapers for jewelry polishing, including their different types, grit sizes, and applications. We will also provide valuable insights and tips to help you achieve the perfect shine for your precious pieces.

Best Sandpaper for Jewelry

Jewelry Sandpaper

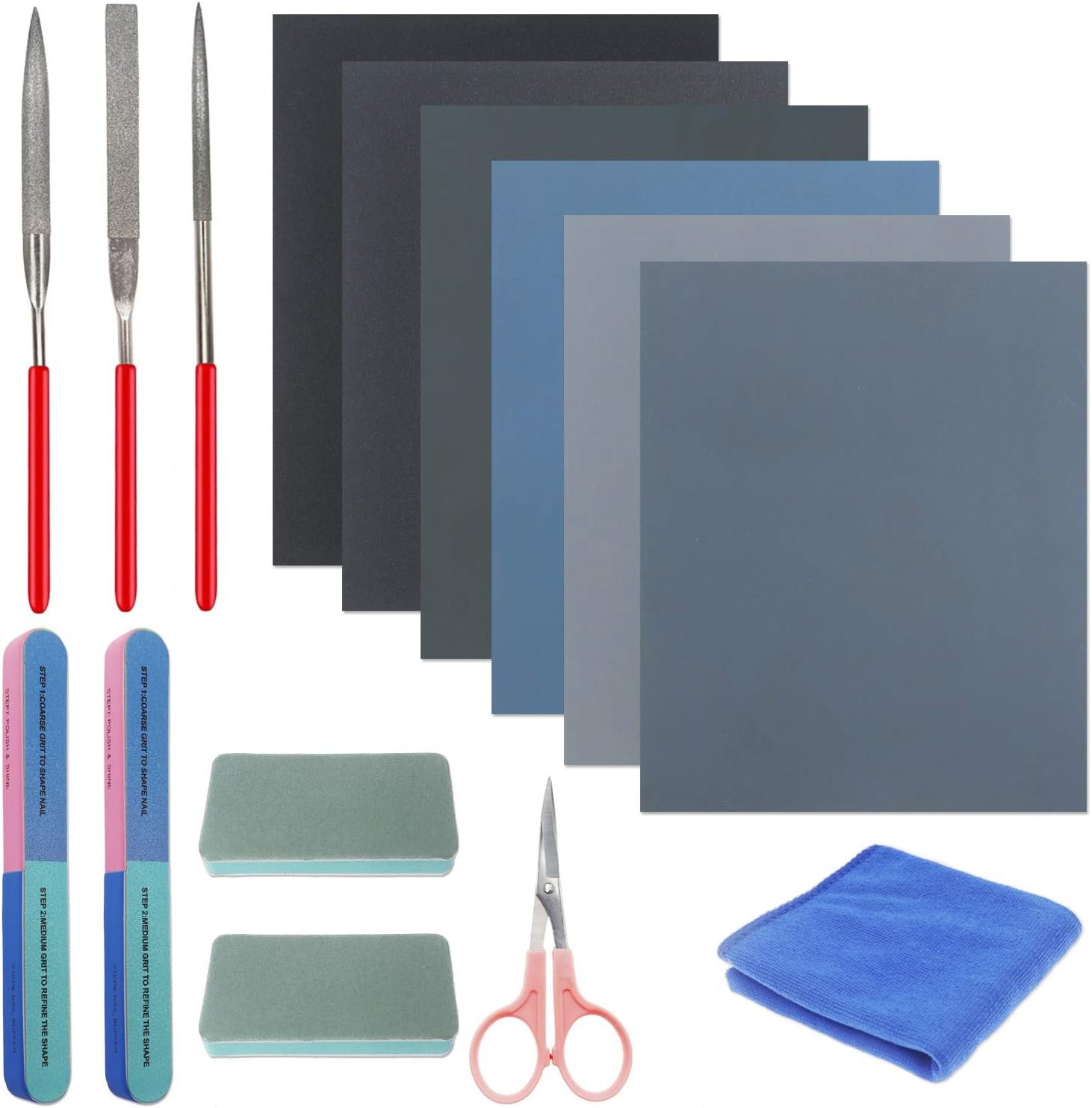

Jewelry Cleaning Kit

Product Features

The Importance of Sandpaper in Jewelry Polishing

Sandpaper, also known as abrasive paper, is a versatile tool used in various industries, including jewelry making. It consists of a backing material coated with abrasive particles, which are responsible for removing imperfections and creating a smooth surface. In jewelry polishing, sandpaper is used to remove scratches, blemishes, and oxidation from metal surfaces, resulting in a high-quality finish.

Choosing the right sandpaper for jewelry polishing is crucial as different types and grit sizes offer varying levels of abrasiveness. Using the wrong sandpaper can lead to uneven surfaces, scratches, or even damage to your jewelry. Therefore, it is essential to understand the different types of sandpapers available and their specific applications.

Types of Sandpapers for Jewelry Polishing

There are several types of sandpapers commonly used in jewelry polishing. Each type has its own unique characteristics and is suitable for specific materials and applications. Let’s explore some of the most popular types:

1. Silicon Carbide Sandpaper

Silicon carbide sandpaper is one of the most commonly used types for jewelry polishing. It is highly abrasive and works well on metals such as gold, silver, and platinum. Silicon carbide sandpaper is available in various grit sizes, ranging from coarse to fine. Coarse grits, such as 80 or 120, are ideal for removing deep scratches or oxidation, while finer grits, such as 400 or 600, are perfect for achieving a smooth, polished finish.

2. Aluminum Oxide Sandpaper

Aluminum oxide sandpaper is another popular choice for jewelry polishing. It is less abrasive than silicon carbide sandpaper and is suitable for softer metals like copper or brass. Aluminum oxide sandpaper is available in different grit sizes, allowing you to choose the right level of abrasiveness for your specific needs. Coarse grits, such as 120 or 180, are ideal for initial shaping and removing scratches, while finer grits, such as 320 or 400, can be used for final polishing.

3. Garnet Sandpaper

Garnet sandpaper is a natural abrasive that is commonly used for woodworking but can also be used for jewelry polishing. It is less aggressive than silicon carbide or aluminum oxide sandpaper, making it suitable for delicate metals like silver or gold. Garnet sandpaper is available in various grit sizes, ranging from coarse to fine. Coarse grits, such as 80 or 120, can be used for initial shaping, while finer grits, such as 220 or 320, are perfect for achieving a smooth finish.

Choosing the Right Grit Size

When it comes to sandpaper, the grit size refers to the number of abrasive particles per square inch. The higher the grit number, the finer the abrasive particles and the smoother the finish. Choosing the right grit size is crucial for achieving the desired level of polish. Here are some general guidelines:

- Coarse Grit Sandpaper (80-120): Ideal for removing deep scratches, oxidation, or shaping metal surfaces.

- Medium Grit Sandpaper (180-320): Suitable for refining the surface, removing smaller scratches, and preparing for final polishing.

- Fine Grit Sandpaper (400-600): Perfect for achieving a smooth, polished finish and removing any remaining imperfections.

It is important to note that the specific grit sizes may vary depending on the manufacturer and the type of sandpaper. Always refer to the manufacturer’s recommendations for the best results.

Applications of Sandpapers in Jewelry Polishing

Sandpapers can be used in various applications during the jewelry polishing process. Here are some common applications:

1. Surface Preparation

Before polishing your jewelry, it is essential to prepare the surface by removing any scratches, blemishes, or oxidation. Coarse grit sandpapers, such as 80 or 120, are ideal for this initial stage. Start by sanding the surface in a circular motion, applying even pressure. Gradually move to finer grits, such as 180 or 320, to refine the surface and remove smaller scratches.

2. Polishing

Once the surface is prepared, it is time to move on to the polishing stage. Fine grit sandpapers, such as 400 or 600, are perfect for achieving a smooth, polished finish. Use a gentle circular motion and apply light pressure to avoid creating new scratches. Keep in mind that polishing compounds or pastes can also be used in conjunction with sandpaper to enhance the shine and remove any remaining imperfections.

3. Final Touches

After polishing, you may notice some fine scratches or imperfections on the surface. To remove these, you can use ultra-fine grit sandpapers, such as 800 or 1000. Be careful not to over-sand the surface, as this can result in a dull finish. Always follow up with a final polishing step using a soft cloth or a polishing wheel to achieve the perfect shine.

Tips for Using Sandpapers in Jewelry Polishing

Here are some valuable tips to keep in mind when using sandpapers for jewelry polishing:

- Always start with a coarser grit sandpaper and gradually move to finer grits for the best results.

- Use a sanding block or a sanding stick to ensure even pressure and avoid uneven surfaces.

- Wet sanding can be beneficial for certain materials, such as wood or acrylic, as it helps to prevent clogging and provides a smoother finish.

- Regularly clean the sandpaper surface or replace it when it becomes clogged with debris or metal particles.

- Always wear protective gloves and eyewear when working with sandpapers to avoid injury.

Conclusion

Choosing the right sandpaper is essential for achieving the perfect shine in jewelry polishing. Silicon carbide, aluminum oxide, and garnet sandpapers are some of the most popular types used in the industry. The grit size of the sandpaper determines its level of abrasiveness, with coarse grits suitable for initial shaping and fine grits ideal for achieving a smooth, polished finish. By understanding the different types of sandpapers and their applications, as well as following the tips provided, you can confidently polish your jewelry to perfection.