When it comes to working with stone surfaces, whether it’s for a DIY project or professional use, selecting the right sandpaper is crucial. The right sandpaper can make all the difference in achieving a smooth and polished finish. With a wide range of options available, it can be overwhelming to choose the right sandpaper for your specific needs. In this article, we will explore the different types of sandpaper, their grit levels, and how to select the best sandpaper for stone surfaces.

The Best Sandpaper for Stone

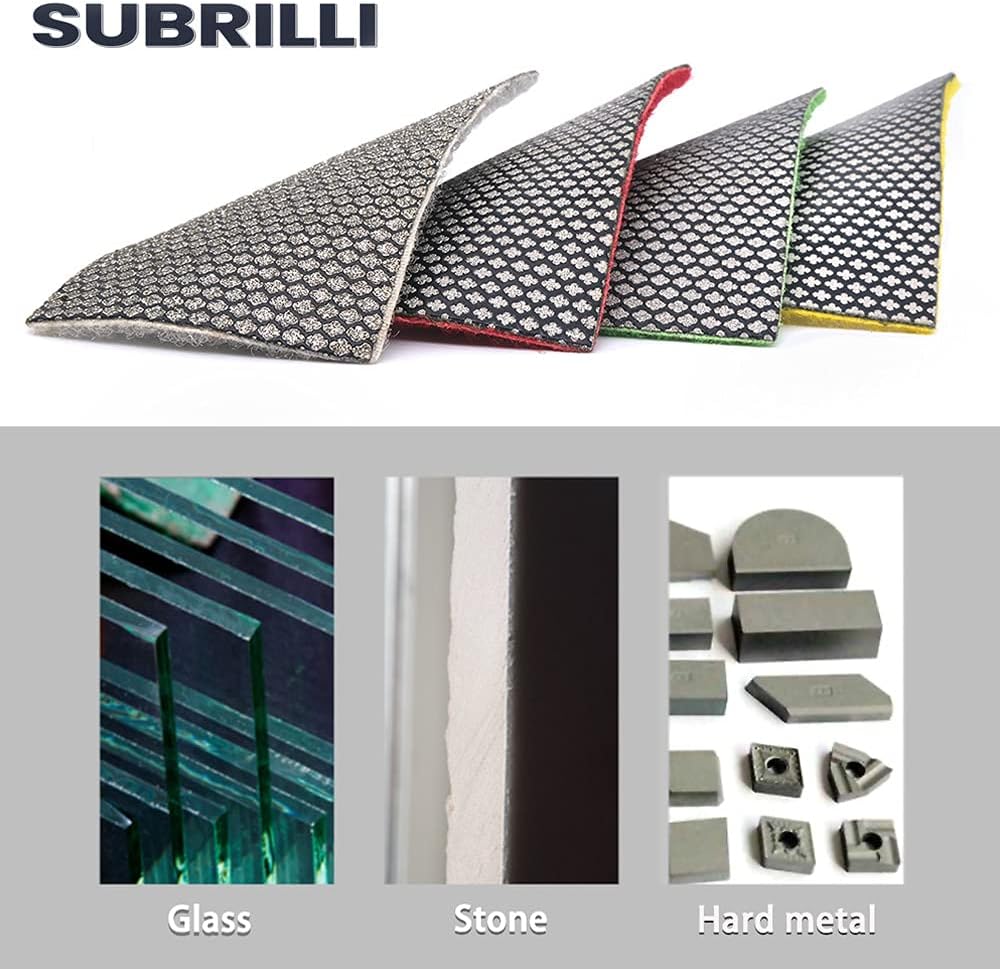

SUBRILLI Diamond Sandpaper 2-Pack

BLACK+DECKER 2.0 Amp Electric 1/4 Sheet Orbit Sander

Aouker HS85180 Hand Sander

The Basics of Sandpaper

Sandpaper, also known as abrasive paper, is a versatile tool used for smoothing and polishing various surfaces. It consists of a backing material coated with abrasive particles. The abrasive particles are typically made of minerals such as aluminum oxide, silicon carbide, or garnet. These minerals are chosen for their hardness and durability.

Sandpaper comes in various forms, including sheets, sanding blocks, rolls, discs, and sponges. Each form has its own advantages and is suitable for different applications. For stone surfaces, sandpaper sheets and sanding blocks are commonly used.

Grit Levels: Understanding the Numbers

One of the most important factors to consider when selecting sandpaper is the grit level. Grit refers to the size of the abrasive particles on the sandpaper. The higher the grit number, the finer the particles and the smoother the finish.

Common grit levels for sandpaper range from coarse to fine, typically starting from 40 grit and going up to 2000 grit or higher. Coarse grit sandpaper, such as 40 or 60 grit, is used for heavy material removal and shaping rough surfaces. Fine grit sandpaper, such as 400 or 600 grit, is used for final smoothing and polishing.

It’s important to note that different materials require different grit levels. For stone surfaces, a range of grit levels may be needed depending on the type of stone and the desired finish. Harder stones like granite or marble may require coarser grits, while softer stones like limestone or sandstone may require finer grits.

Types of Sandpaper for Stone Surfaces

There are several types of sandpaper available for stone surfaces, each with its own characteristics and applications. Let’s explore some of the most commonly used types:

1. Silicon Carbide Sandpaper

Silicon carbide sandpaper is a popular choice for stone surfaces due to its aggressive cutting action and durability. It is available in various grit levels and is suitable for both wet and dry sanding. Silicon carbide sandpaper is particularly effective for shaping and smoothing hard stones like granite or concrete.

2. Aluminum Oxide Sandpaper

Aluminum oxide sandpaper is another commonly used option for stone surfaces. It is known for its versatility and durability. Aluminum oxide sandpaper is available in a wide range of grit levels and is suitable for both hand sanding and power sanding. It is effective for smoothing and polishing various types of stones.

3. Garnet Sandpaper

Garnet sandpaper is a natural abrasive that is often used for wood sanding but can also be used for stone surfaces. It is available in various grit levels and is known for its excellent finish. Garnet sandpaper is less aggressive compared to silicon carbide or aluminum oxide, making it suitable for final smoothing and polishing of softer stones.

Factors to Consider When Selecting Sandpaper

When selecting sandpaper for stone surfaces, there are several factors to consider:

1. Material Hardness

The hardness of the stone surface plays a significant role in determining the appropriate grit level. Harder stones require coarser grits for effective material removal, while softer stones require finer grits for a smoother finish.

2. Desired Finish

Consider the desired finish for your stone surface. If you are looking for a rougher texture or need to remove a significant amount of material, a coarser grit may be suitable. For a smoother and polished finish, a finer grit is recommended.

3. Wet or Dry Sanding

Some sandpapers are designed for wet sanding, while others are suitable for dry sanding. Wet sanding is often preferred for stone surfaces as it helps to reduce dust and provides better lubrication. Consider whether you will be sanding the stone surface wet or dry and choose the appropriate sandpaper accordingly.

4. Application Method

Consider the application method you will be using. If you are sanding by hand, sandpaper sheets or sanding blocks may be more suitable. If you are using a power sander, sandpaper discs or rolls may be more convenient.

Tips for Sanding Stone Surfaces

Here are some tips to keep in mind when sanding stone surfaces:

- Always wear protective gear, including safety goggles and a dust mask, to protect yourself from flying debris and dust particles.

- Start with a coarser grit sandpaper to remove any roughness or imperfections on the stone surface.

- Use light pressure and make even strokes to ensure an even and consistent finish.

- Regularly check the sandpaper for wear and replace it when necessary to maintain optimal performance.

- After sanding, clean the stone surface thoroughly to remove any dust or debris before proceeding to the next grit level.

Conclusion

Selecting the right sandpaper for stone surfaces is essential for achieving a smooth and polished finish. Understanding the different types of sandpaper and their grit levels is crucial in making an informed decision. Consider factors such as material hardness, desired finish, wet or dry sanding, and application method when selecting sandpaper. By following the tips and guidelines provided in this article, you can confidently choose the appropriate sandpaper for your stone surface projects and achieve professional-quality results.